Constant torque boosting and pulling locker and chassis bracket device and cabinet

A technology of fixed torque and locker, which is applied in the direction of support structure installation, electrical equipment shell/cabinet/drawer, electrical components, etc., and can solve the problem that the locker cannot assist the insertion and removal of the chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

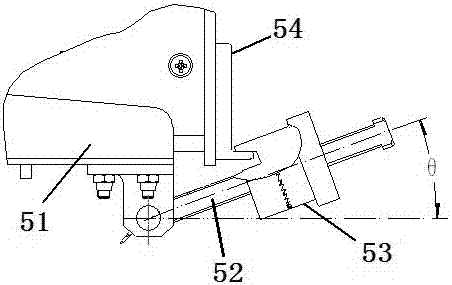

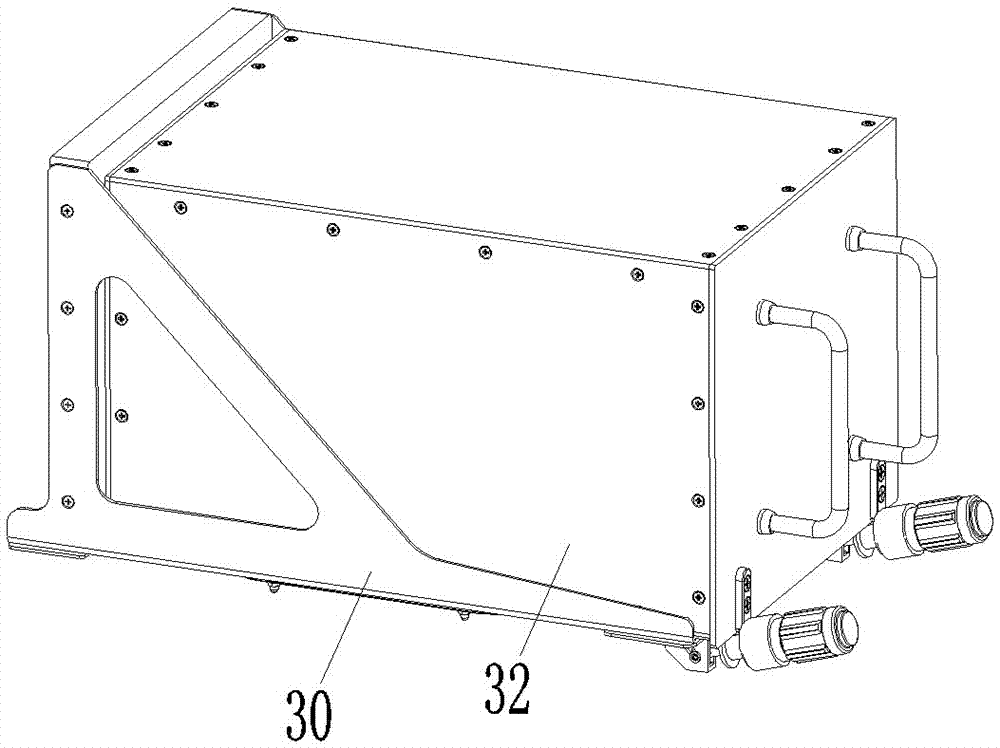

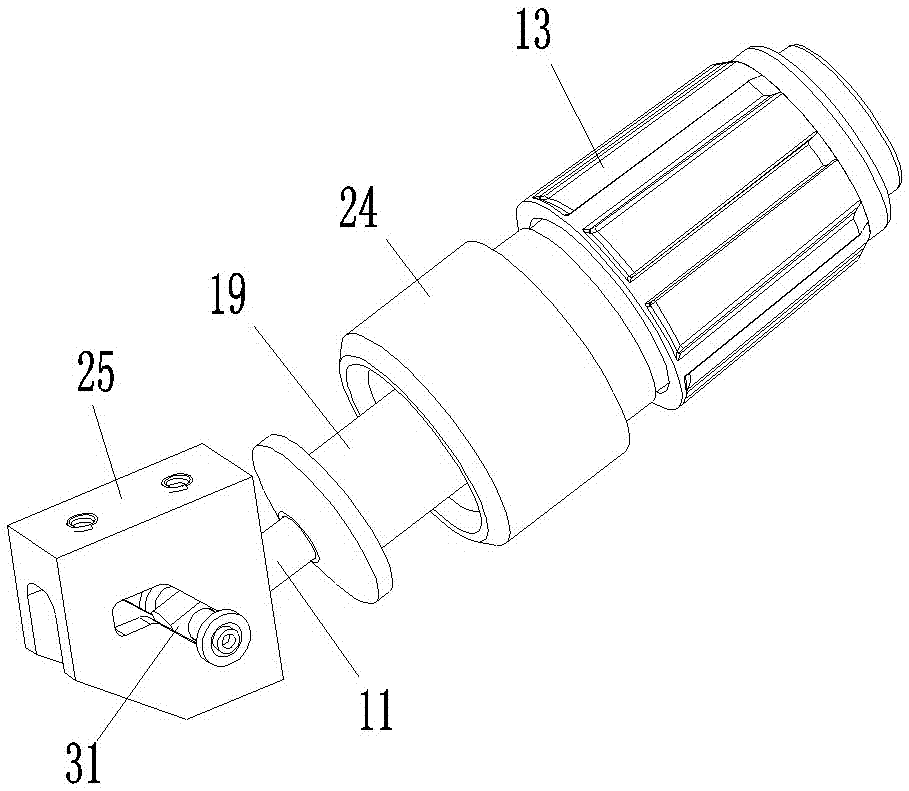

[0029] Embodiments of torque-assisted pull-out lockers, such as Figure 2-12 As shown, the locking device includes a lock rod 11, a screw sleeve 12, a screw cap 13, a transmission steel ball 14, a transmission piece 15, a pressing piece 16, a force limiting spring 17, a spring support sleeve 18, an output sleeve 19, and a transmission seat 20 , ball 21, push spring 22, drive sleeve 23, lock cap 24 and lock seat 25.

[0030] The front end of the locking rod 11 is provided with a hinge hole and a threaded section is provided between the two ends.

[0031] The position between the two ends of the screw sleeve 12 is provided with an internal thread segment, which corresponds to the thread segment on the lock bar 11, and the screw sleeve 12 is exactly through the connection between its internal thread segment and the thread segment of the lock bar 11. Cooperate and threadedly assembled on the lock rod 11, because both of them are not all provided with threads, so the rear end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com