Motor driving circuit

a technology of motor driving and circuit, which is applied in the direction of process and machine control, electronic commutators, instruments, etc., can solve the problems of increasing the circuit size of digital filters, and achieve the effect of suppressing the increase in the circuit size and enhancing the starting characteristi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

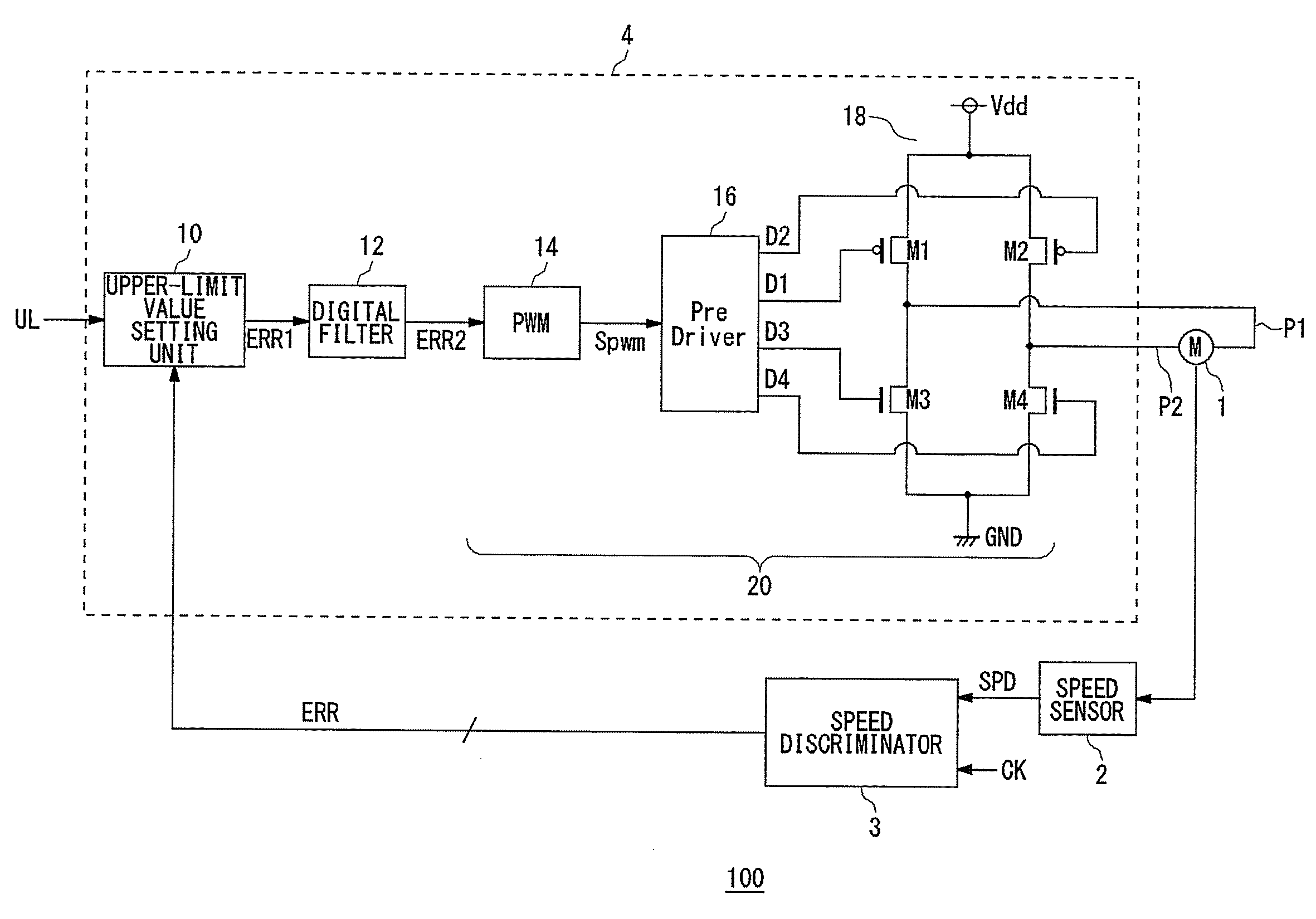

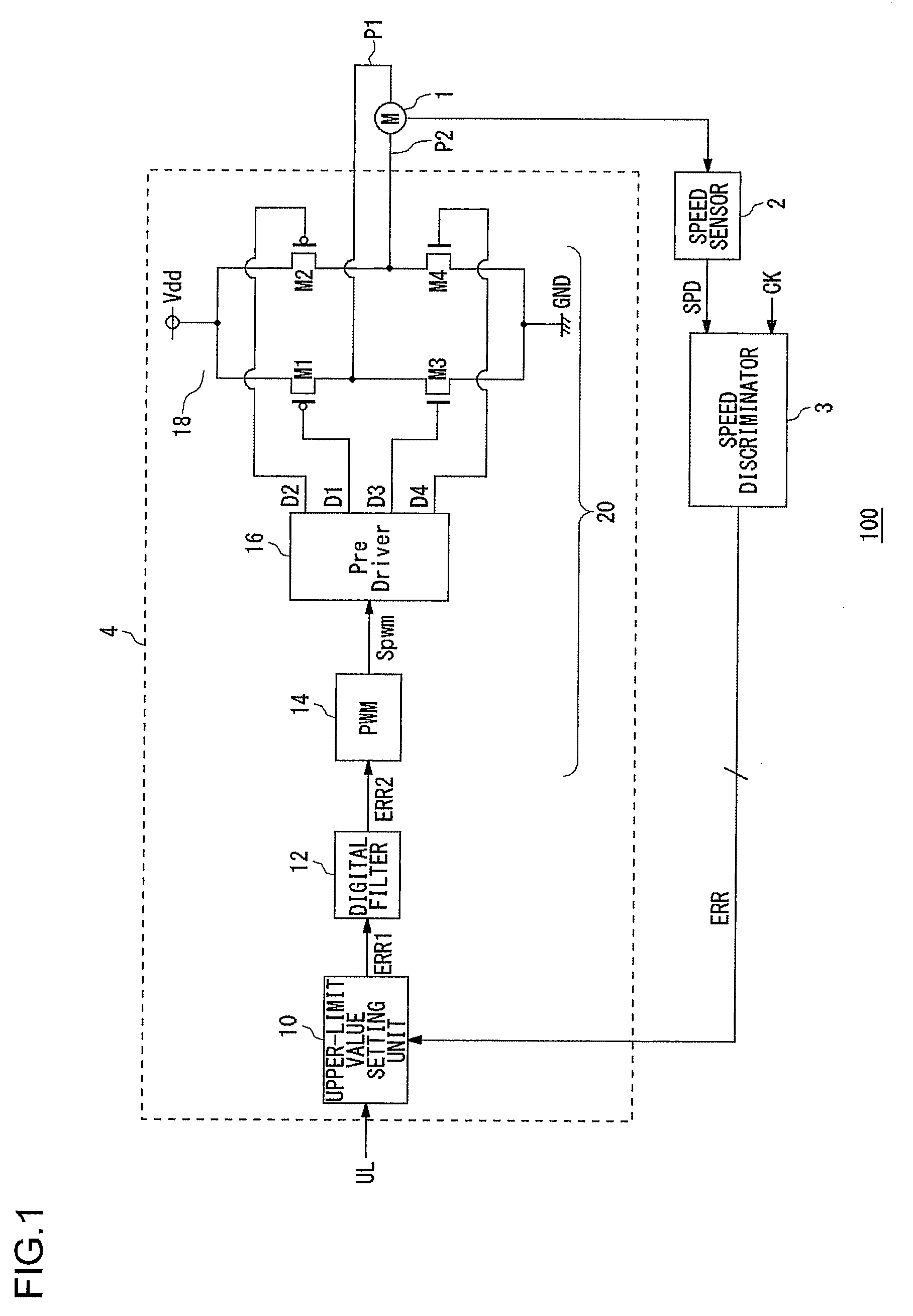

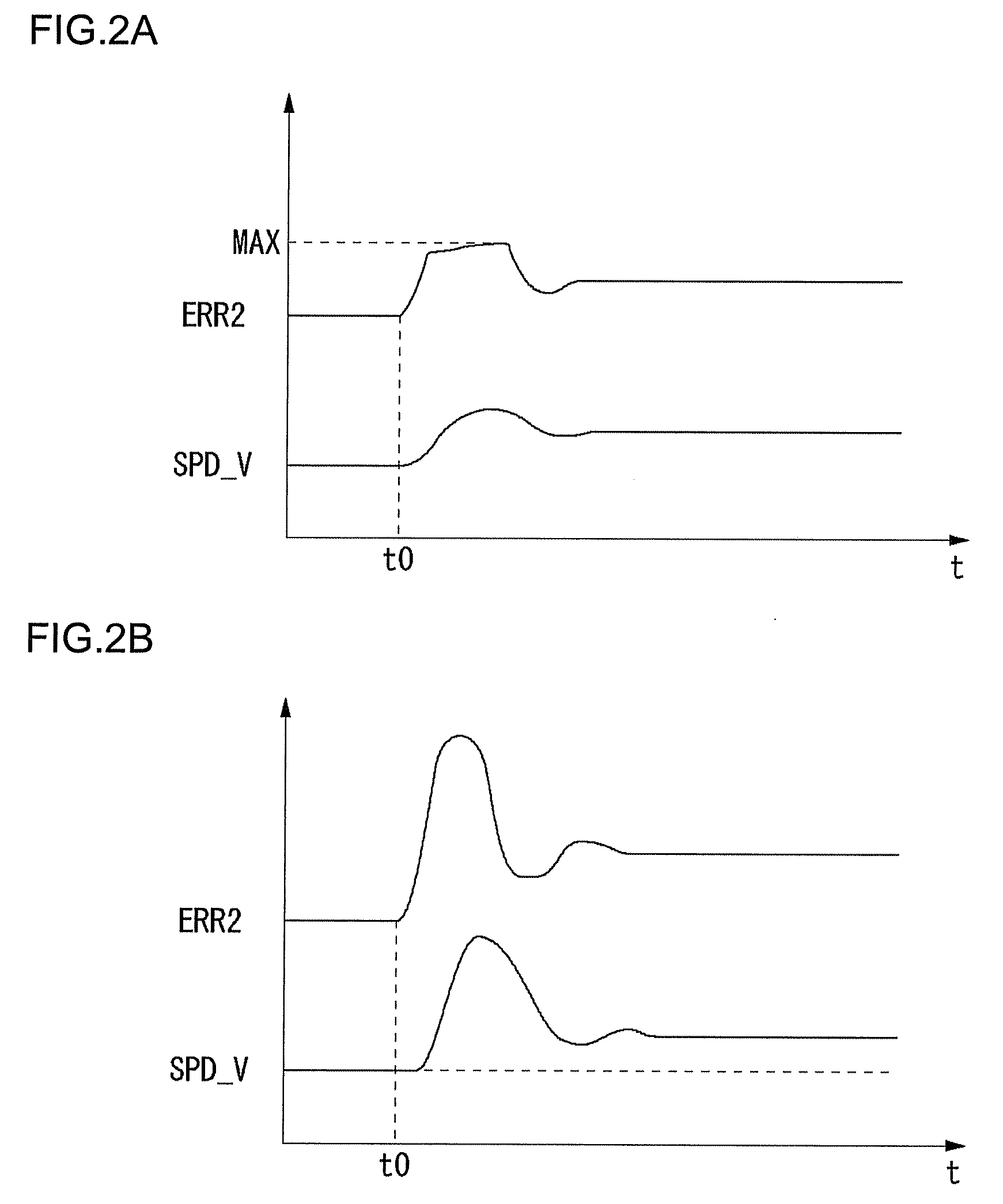

[0028]FIG. 1 is a block diagram showing a configuration of a motor driving apparatus 100 according to a first embodiment. FIG. 1 shows a motor 1, which a subject to be driven, together with the motor driving apparatus 100. The motor 1 and the motor driving apparatus 100 are mounted to an electronic apparatus having a movable unit. The motor 1 is connected to the movable unit of the electronic apparatus. The rotation speed of the motor 1 is controlled by the motor driving apparatus 100, whereby the motor 1 drives the movable unit. For example, the electronic apparatuses include a digital still camera or digital video camera, wherein the motor 1 is utilized for moving a lens or shutter.

[0029]The motor driving apparatus 100 drives the motor in such a manner that the rotation speed thereof approaches a desired target value, while monitoring the rotation speed of the motor 1. The motor driving apparatus 100 has a speed sensor 2, speed discriminator 3, and motor driving circuit 4.

[0030]Th...

second embodiment

[0051]In the motor driving apparatus 100 according to the above-mentioned first embodiment, the upper-limit value setting unit 10 is provided to set the upper limit value to the error signal ERR, whereby the prevention of the overshoot and the shortening of the starting time can be realized. The motor driving apparatus 100 according to the second embodiment has a feature in the digital filter 12, and the other configurations are the same as those of the motor driving apparatus 100 according to the first embodiment shown in the block diagram of FIG. 1.

[0052]FIGS. 3A and 3B are circuit diagrams showing the configuration of the digital filter 12 in the motor driving apparatus 100 according to the second embodiment. FIG. 3A is a diagram showing the configuration of the digital filter 12, and FIG. 3B shows the configuration of an analog filter that is equivalent to FIG. 3A.

[0053]An analog filter 12′ in FIG. 3B is a low-pass filter including capacitors C1 and C2 and resistor R1. The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com