Top and foldable end frame assembly for pallet container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

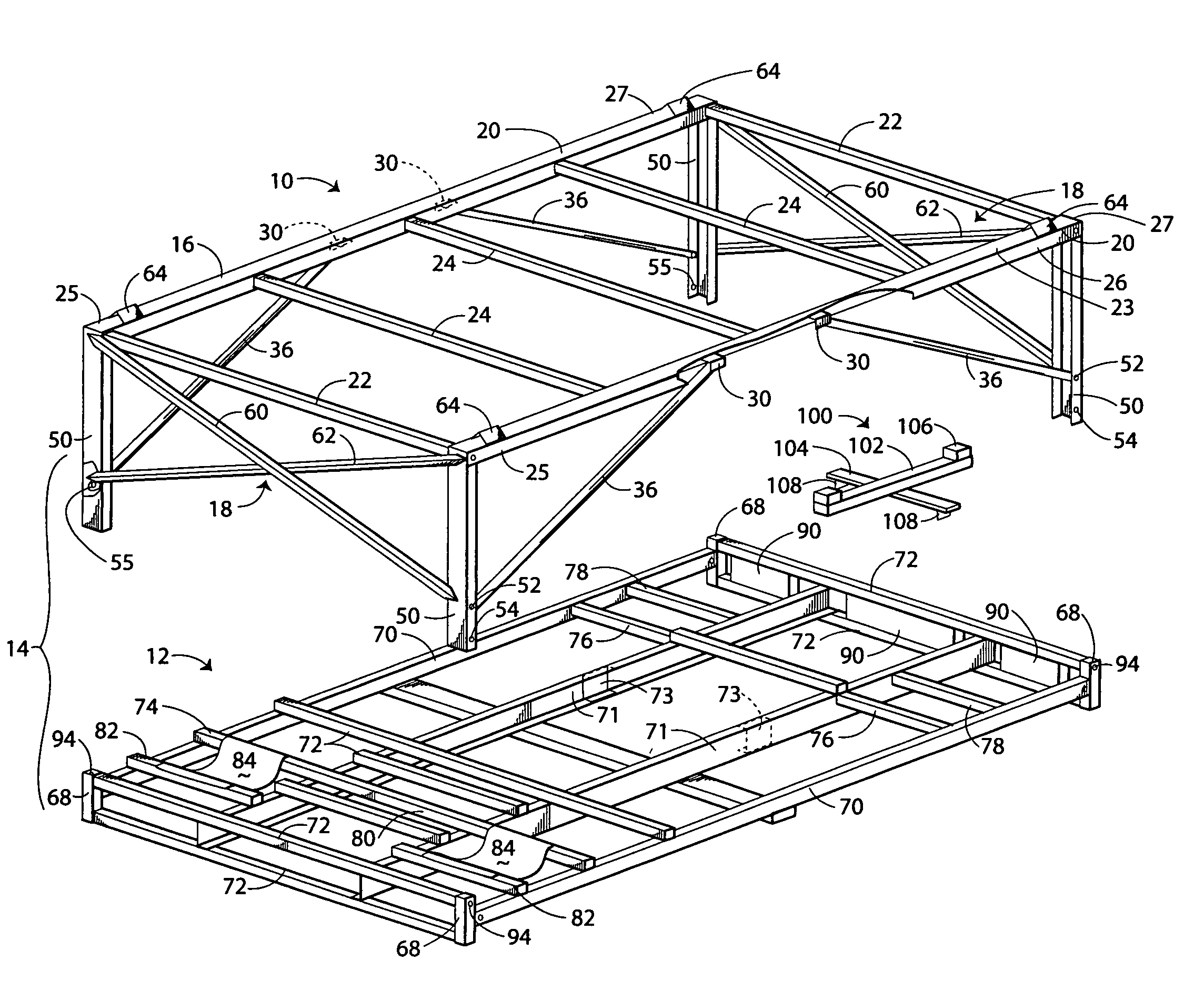

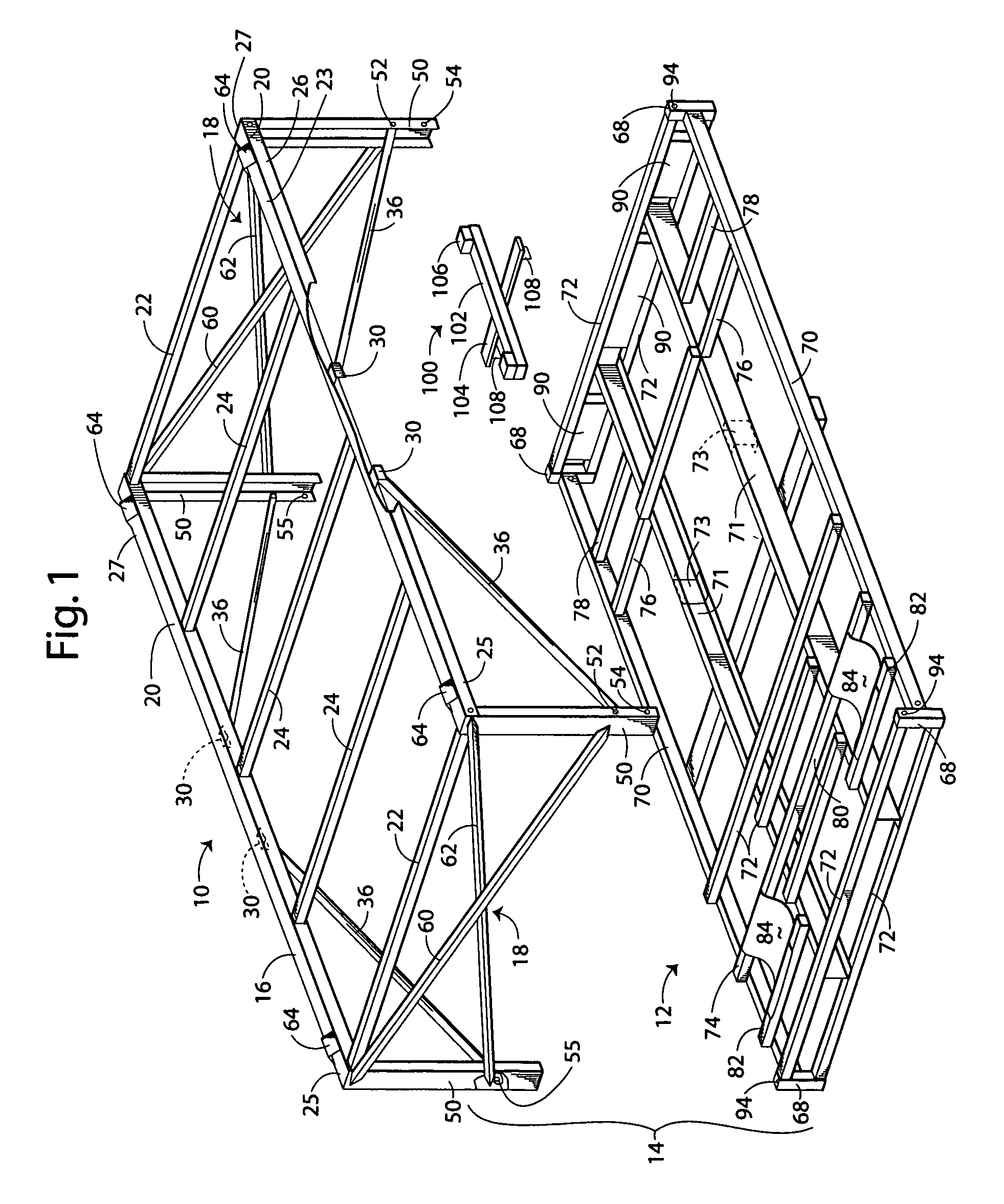

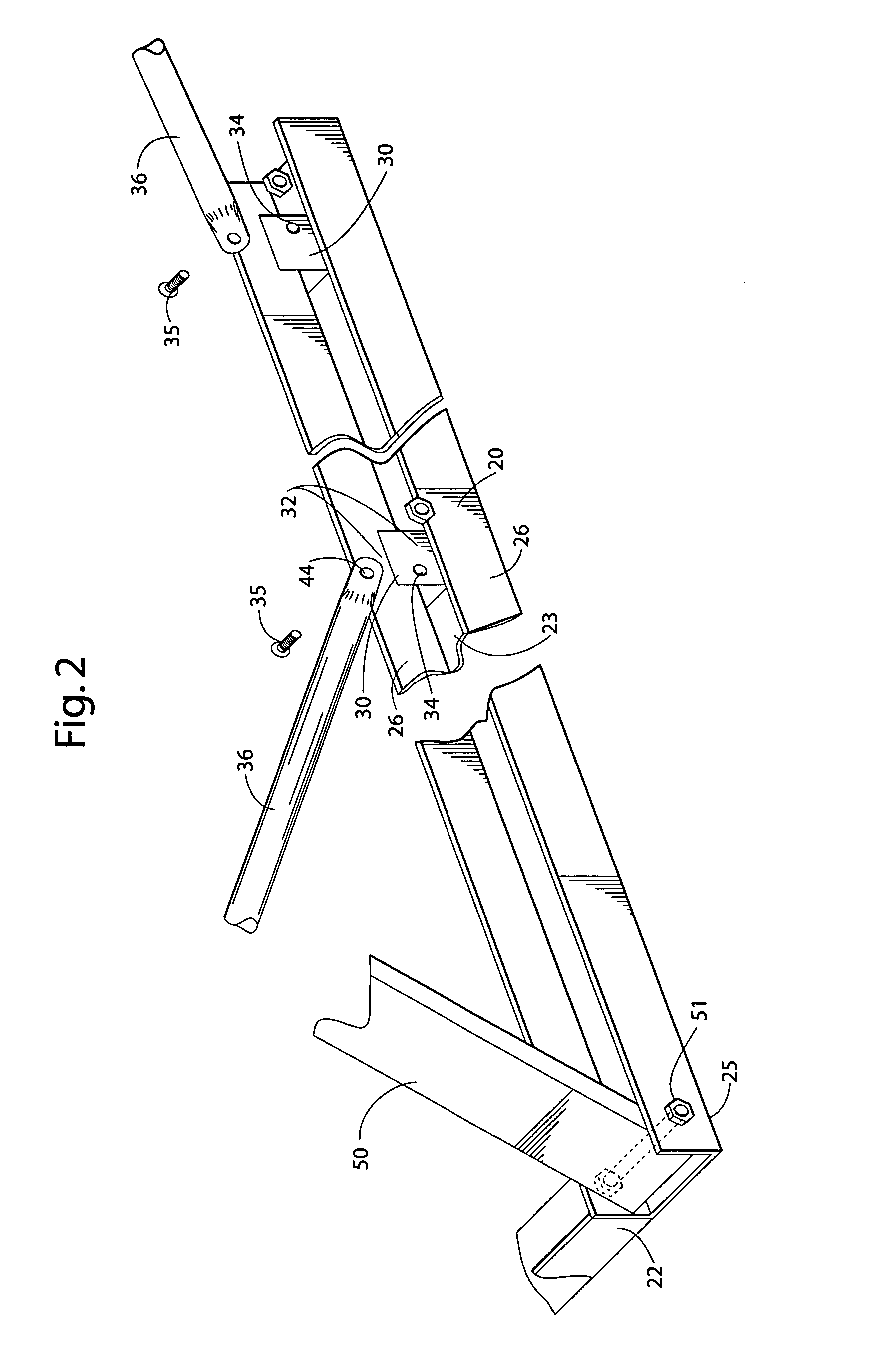

[0017]Referring now in more detail to the drawings, in which like numerals indicate like parts throughout the several views, FIG. 1 illustrates in perspective view a top and end frame assembly 10 according to the present invention and exploded from a pallet 12 for use in a frame crate generally 14 for packaging, storing, and shipping heavy durable goods, such as a wheeled lawn and garden tractor. The top and end frame assembly 10 comprises a top frame generally 16 and two opposing end frames generally 18. The top frame 16 includes a pair of spaced-apart stringers 20, which interconnect with spaced-apart transverse members 22, 24. The stringers 20 are open-sided U-shaped channels having a back 23 and opposing side walls 26 with opposing distal ends 25, 27. The “open” side of the stringers 20 face towards the pallet 12. The outer transverse members 22 are angle members. The inner transverse members 24 are angle members inverted to provide an apex 28 pointing in a vertical upward orien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com