Self-jacking construction platform integrating vertical transportation equipment and mold base

A technology of vertical transportation and construction platform, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc. It can solve the problem that the elevator cannot run above the structural construction layer, cannot place large construction equipment, and is suitable for supporting box beams. problems such as poor performance, to achieve the effect of safe and reliable construction operation, saving time and cost, and saving construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

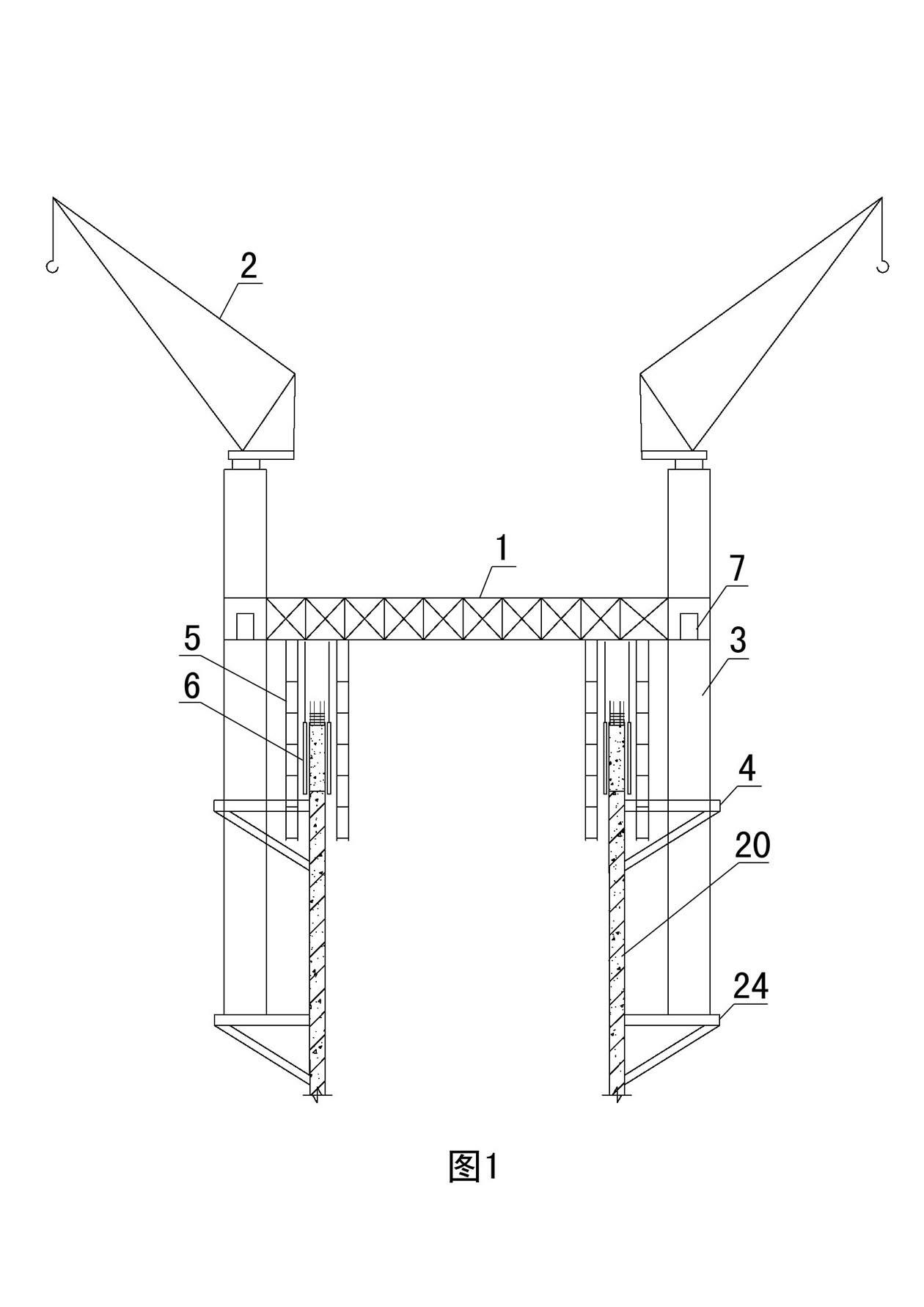

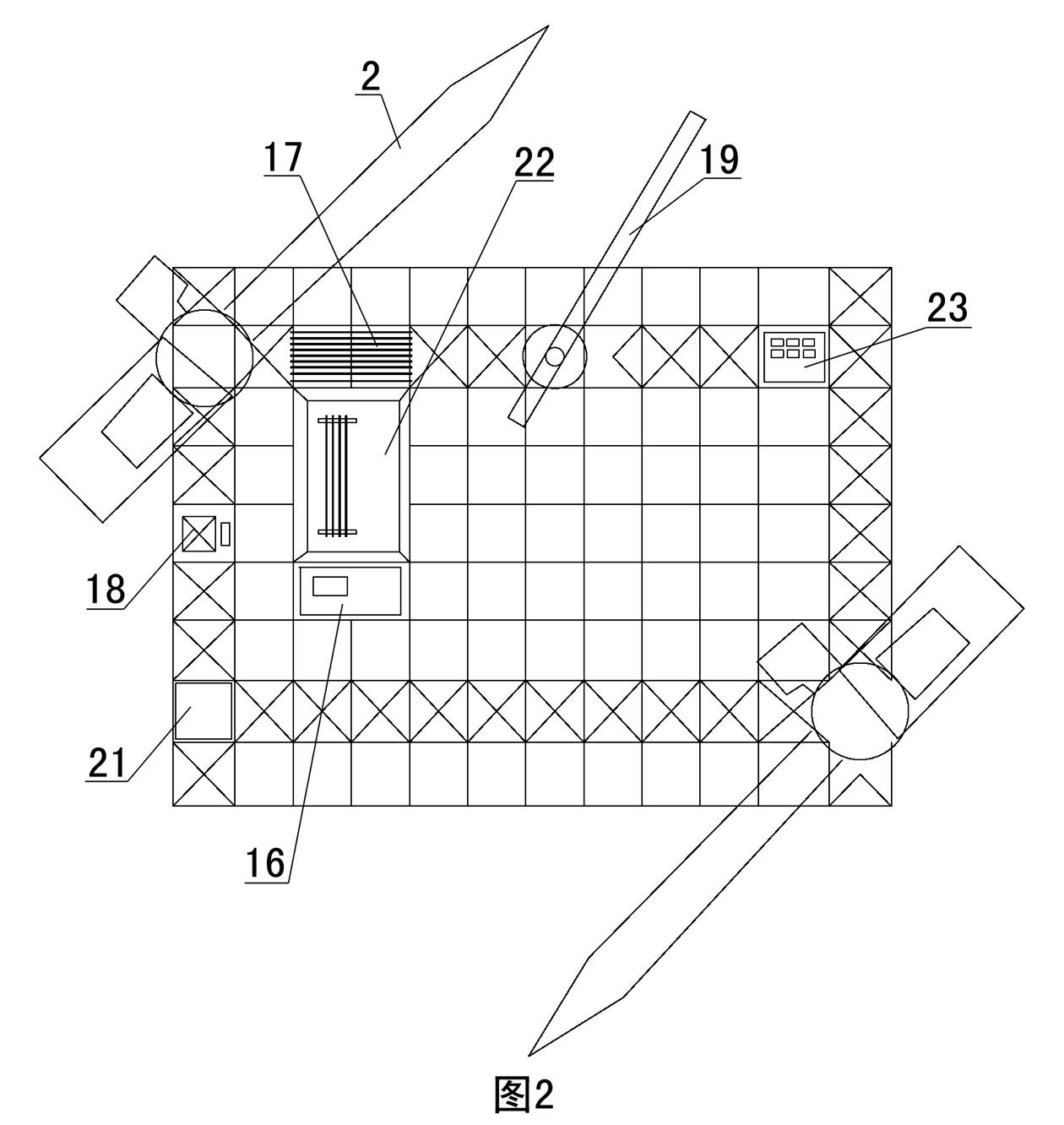

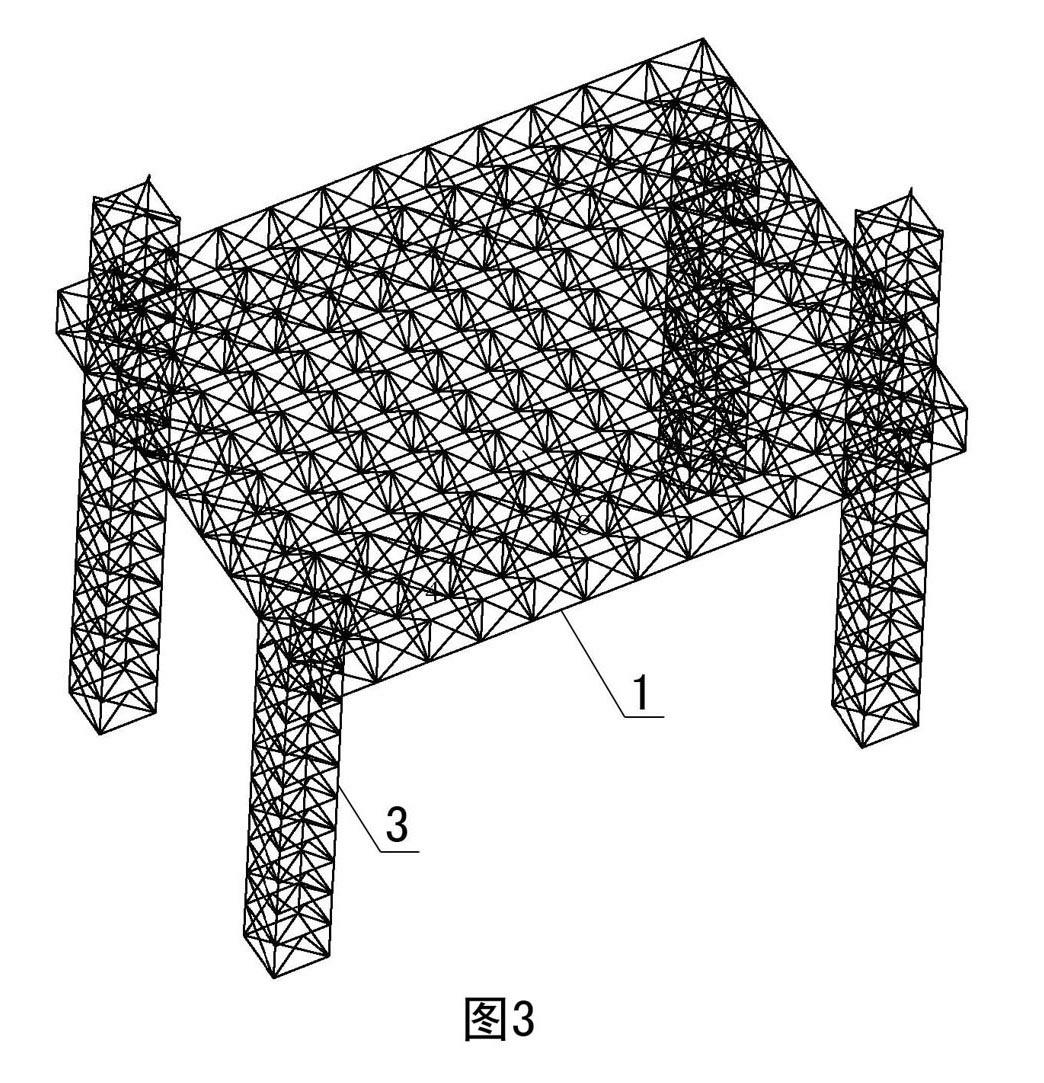

[0058] Examples see figure 1 , figure 2 As shown, this self-jacking construction platform integrating vertical transportation equipment and formwork includes a steel platform, construction equipment connected to the steel platform, and a core tube 20 that connects the steel platform to the high-rise building being constructed. The top supporting jacking system, the steel platform is a space steel truss platform 1; the construction equipment includes a hanger 5 and a template 6 hung on the space steel truss platform 1, Tower crane 2, concrete placing machine 19, office rest area 21, simple processing plant 22, monitoring and maintenance system 23, and construction elevator 18 connected between the space steel truss platform 1 and the core tube 20.

[0059] The tower crane 2 is the main hoisting equipment of the present invention, which can be used for the vertical transportation of materials and the installation of heavy components. The tower crane 2 and the space steel truss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com