Composite phosphorus-free corrosion and scale inhibitor and its application

A corrosion and scale inhibitor, phosphorus-free corrosion inhibition technology, applied in complex/solubilizer treatment, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problem of long-term operation without production equipment, damage Ecological balance, unfriendly environment and other issues, achieve the effect of reducing bacterial corrosion and moss growth, reducing dosage, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A compound non-phosphorus corrosion and scale inhibitor formula, which is composed of corrosion and scale inhibitor A and corrosion and scale inhibitor B, wherein:

[0025] Corrosion and scale inhibitor A is made by mixing polyepoxysuccinic acid (PESA), sodium gluconate, and water, and the weight ratio of each component is:

[0026] Polyepoxysuccinic acid (PESA) 10 parts

[0027] Sodium Gluconate 50 parts

[0028] 40 parts of water

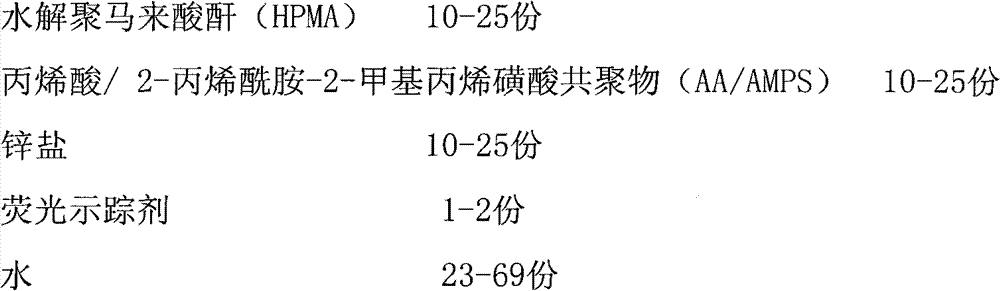

[0029] Corrosion and scale inhibitor B is made by mixing hydrolyzed polymaleic anhydride (HPMA), acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer (AA / AMPS), zinc salt, fluorescent tracer, and water , the weight ratio of each component is:

[0030]

[0031] The zinc salt is zinc sulfate.

[0032] The fluorescent tracer is fluorescent whitening agent ER-II.

[0033] The above-mentioned composite non-phosphorus corrosion and scale inhibitor formula is applied to circulating cooling water, and 30 mg of corr...

Embodiment 2

[0034] Embodiment 2: A compound non-phosphorus corrosion and scale inhibitor formula, which is composed of corrosion and scale inhibitor A and corrosion and scale inhibitor B, wherein:

[0035] Corrosion and scale inhibitor A is made by mixing polyepoxysuccinic acid (PESA), sodium gluconate, and water, and the weight ratio of each component is:

[0036] Polyepoxysuccinic acid (PESA) 20 parts

[0037] Sodium Gluconate 40 parts

[0038] 40 parts of water

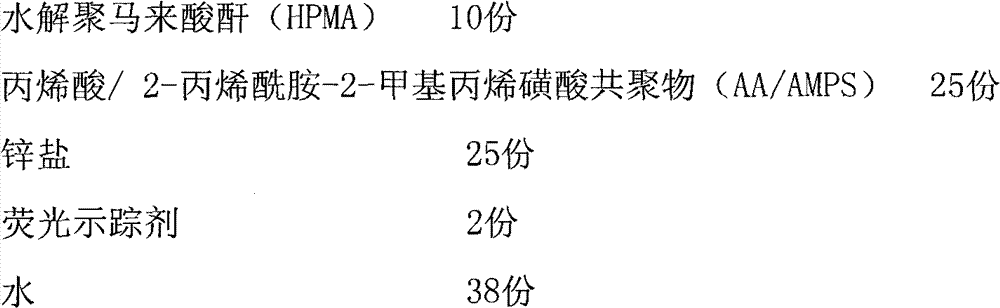

[0039] Corrosion and scale inhibitor B is made by mixing hydrolyzed polymaleic anhydride (HPMA), acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer (AA / AMPS), zinc salt, fluorescent tracer, and water , the weight ratio of each component is:

[0040]

[0041] The zinc salt is zinc sulfate.

[0042] The fluorescent tracer is fluorescent whitening agent BAC-H.

[0043] The above-mentioned composite non-phosphorus corrosion and scale inhibitor formula is applied to circulating cooling water, and 35 mg of corr...

Embodiment 3

[0044]Embodiment 3: A compound non-phosphorus corrosion and scale inhibitor formula, which is composed of corrosion and scale inhibitor A and corrosion and scale inhibitor B, wherein:

[0045] Corrosion and scale inhibitor A is made by mixing polyepoxysuccinic acid (PESA), sodium gluconate, and water, and the weight ratio of each component is:

[0046] Polyepoxysuccinic acid (PESA) 30 parts

[0047] Sodium Gluconate 30 parts

[0048] 40 parts of water

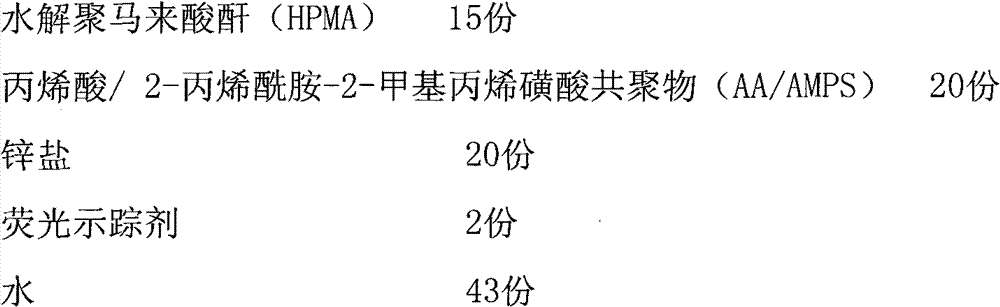

[0049] Corrosion and scale inhibitor B is made by mixing hydrolyzed polymaleic anhydride (HPMA), acrylic acid / 2-acrylamide-2-methylpropenesulfonic acid copolymer (AA / AMPS), zinc salt, fluorescent tracer, and water , the weight ratio of each component is:

[0050]

[0051] The zinc salt is zinc sulfate.

[0052] The fluorescent tracer is fluorescent whitening agent ER-II.

[0053] The above-mentioned composite non-phosphorus corrosion and scale inhibitor formula is applied to circulating cooling water, and 40 mg of corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com