Highly durable high slump loss resistant no-bleeding concrete pump delivering agent

A concrete pump and bleeding technology, which is applied in the field of building materials, can solve the problems of large concrete slump loss, single cementitious material components, and high production costs, and achieve good product homogeneity, good segregation resistance, and high product quality. The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

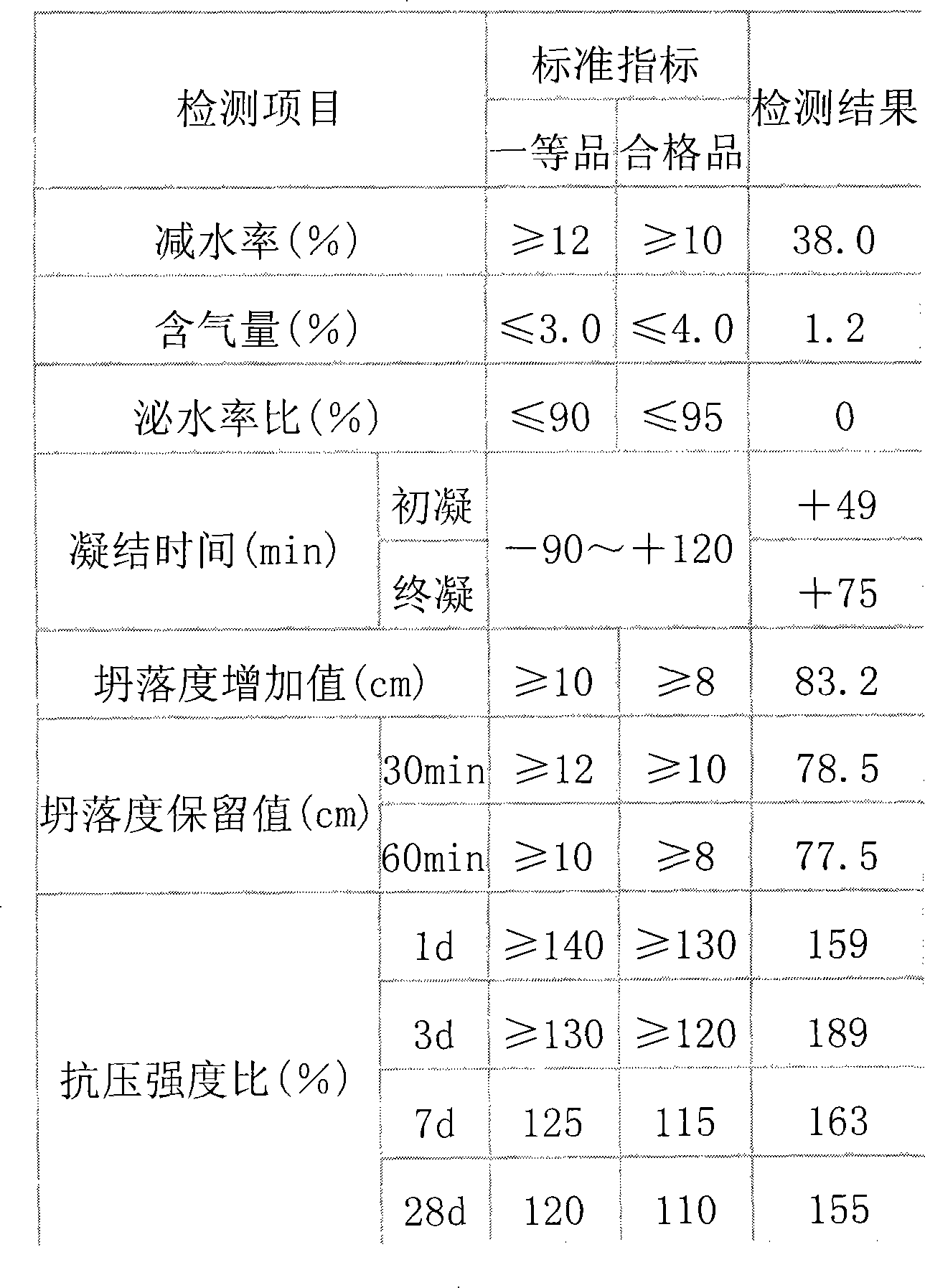

[0022] Embodiment 1: The raw material weight percentage of described high durable high slump and non-bleeding concrete pumping agent consists of: naphthalene series water reducer (β-naphthalene sulfonic acid methylene condensate) 40%, polycarboxylate water reducer 4%, sodium lignosulfonate 2%, sodium gluconate 1%, triterpene saponin 0.5%, carboxymethyl cellulose 1%, silicone oil (sodium methyl siliconate) 0.5%, water 51%; After uniform mixing, add in the cement concrete in the amount of 0.4% (weight ratio) of the cement consumption, and the performance of the concrete is detected as follows:

[0023] Table 1 Test results with standard cement

[0024]

[0025] 1. The water-reducing rate is 37%, which can control the concrete water-cement ratio and fluidity (slump and expansion); the concrete has good water retention, no bleeding, no segregation, and maintains good fluidity and cohesion. 1d concrete compressive strength can be increased by 80%, 28d strength ...

Embodiment 2

[0029] Embodiment 2: The raw material weight percentage of described high durable high slump non-bleeding concrete pumping agent is composed of: naphthalene series water reducer (β-naphthalene sulfonic acid methylene condensate) 38%, polycarboxylate water reducer 3.5%, sodium lignosulfonate 1.9%, sodium gluconate 1.2%, triterpene saponins 0.6%, carboxymethyl cellulose 1.2%, silicone oil (sodium methyl siliconate) 0.6%, water 53%.

[0030] After mixing the components evenly, add 0.4% (weight ratio) of cement into the cement concrete. The performance of the concrete is: the water reducing rate is 36%, the compressive strength of the concrete can be increased by 75% in 1d, and the strength can be increased in 28d. 70%. ;Concrete slump basically has no loss within 120min, and is not affected by temperature changes; the initial setting time is extended by 10h, which improves the early strength of concrete by 80%. The product has good adaptability to cement, and is compatible with ...

Embodiment 3

[0031] Embodiment 3: The raw material weight percent of described high durable high slump and non-bleeding concrete pumping agent is composed of: naphthalene series water reducer (β-naphthalenesulfonic acid methylene condensate) 40%, polycarboxylate water reducer 4%, sodium lignosulfonate 2%, sodium gluconate 0.8%, triterpene saponins 0.5%, carboxymethyl cellulose 0.9%, silicone oil (sodium methyl siliconate) 0.4%, water 51.4%.

[0032]After mixing all the components evenly, add 0.4% of the cement content (weight ratio) into the cement concrete. The performance of the concrete is: the water reducing rate is 36%, the compressive strength of the concrete can be increased by 76% in 1d, and the strength can be increased in 28d. 78%; the slump of concrete within 120 minutes is basically no loss, and is not affected by temperature changes; the initial setting time is extended by 7 hours, and the early strength of concrete is increased by 81%. The product has good adaptability to cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com