Scale and corrosion inhibitor for treating circulating cooling water

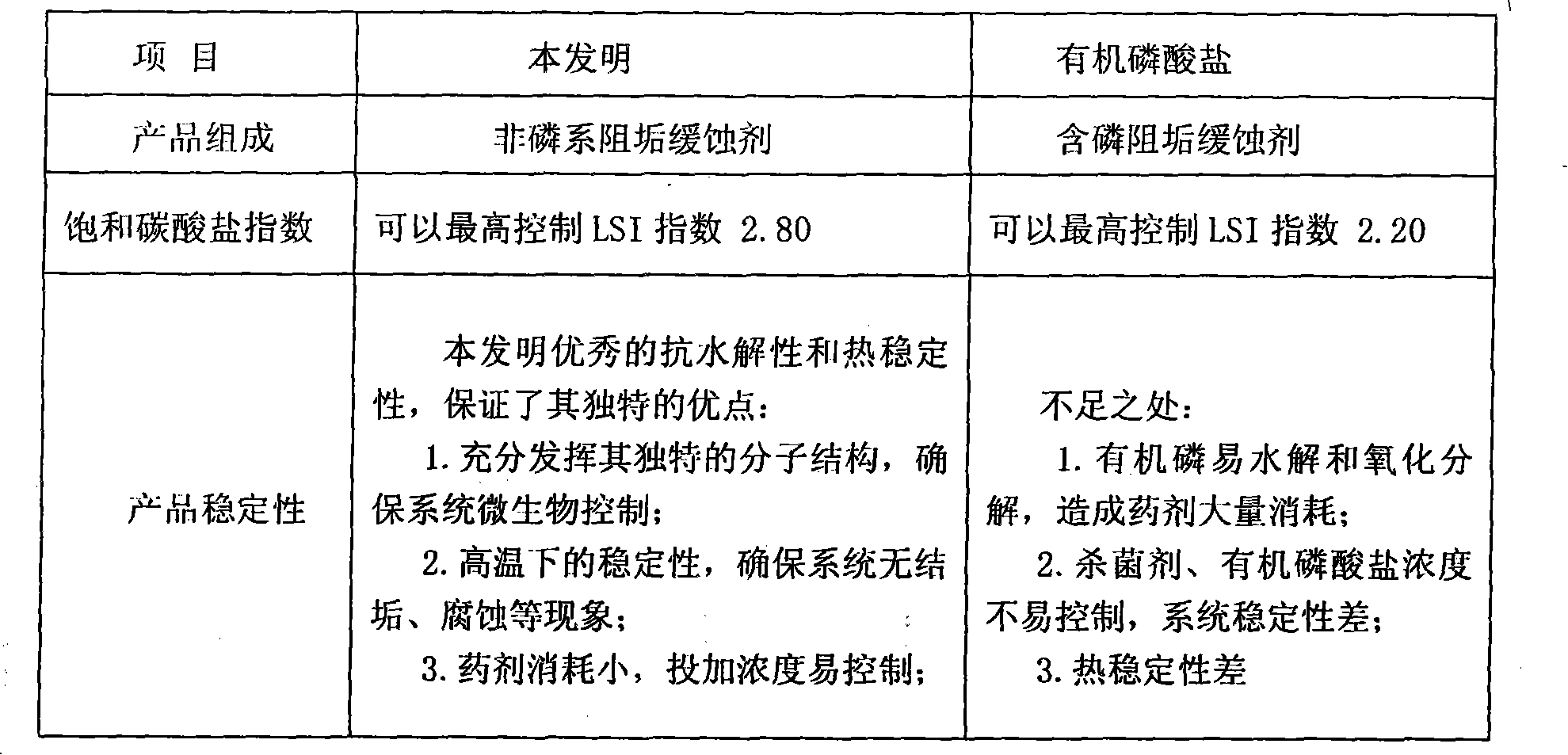

A scale and corrosion inhibitor, treatment cycle technology, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., can solve corrosion perforation, corrosion bacteria and algae, and efficiency reduction of heat exchange equipment and other problems, to achieve the effect of less dosage, stability at high temperature, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0025] Example 2, PESA 12%, sodium gluconate 15%, methyl benzotriazole 3%, imidazoline 1%, deionized 68%.

example 3

[0026] Example 3, PESA 15%, sodium gluconate 18%, methyl benzotriazole 3%, imidazoline 5%, deionized 59%.

[0027] Example 4, PASP 10%, sodium gluconate 10%, methyl benzotriazole 3%, imidazoline 5%, deionization 72%.

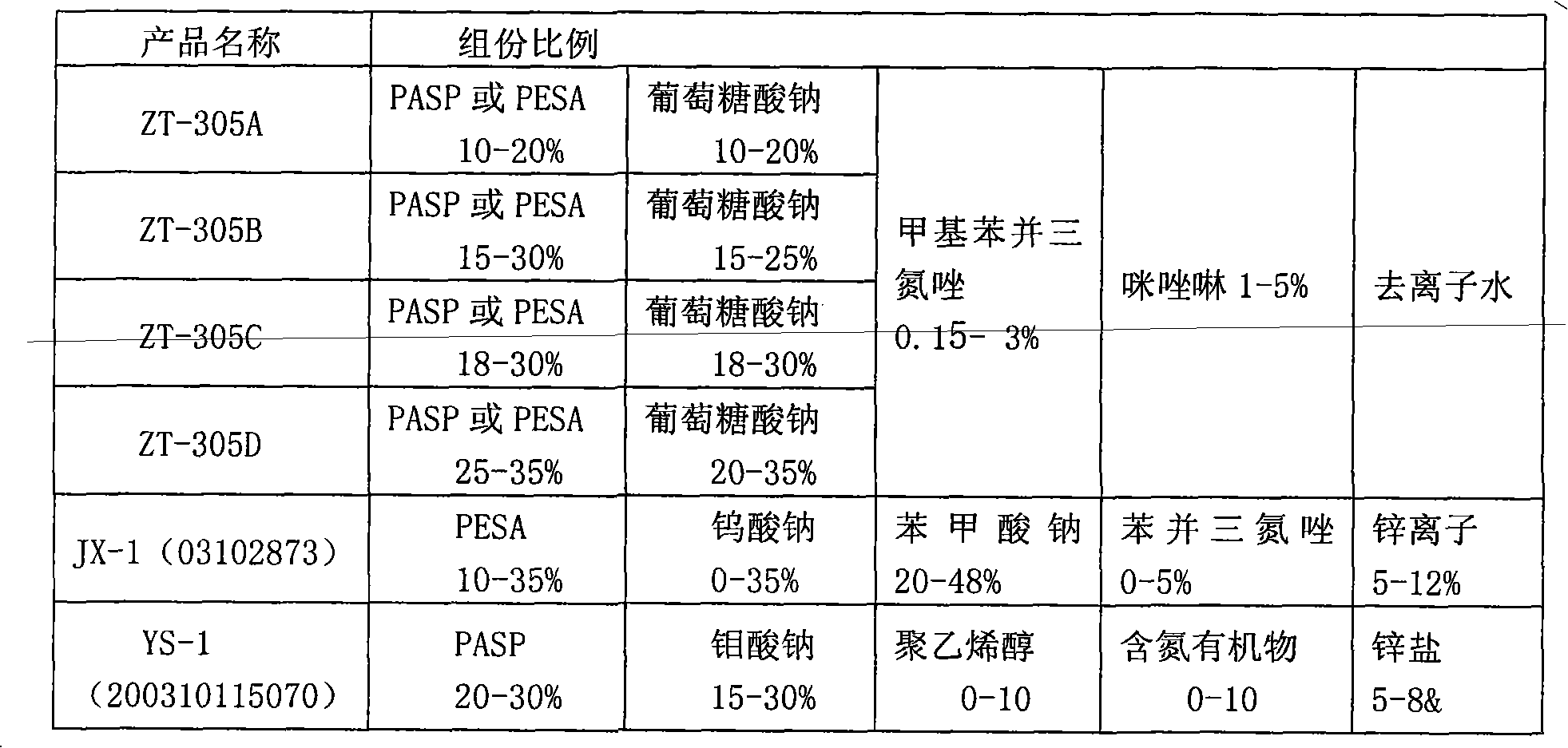

[0028] 2. The ratio of ZT-305B: PASP or PESA 15-30%, sodium gluconate 15-25%, methyl benzotriazole 0.15-3%, imidazoline 1-5%, deionized water balance.

example 1

[0029] Example 1, PASP 15%, sodium gluconate 15%, methyl benzotriazole 0.15%, imidazoline 2%, deionized 67.85%.

[0030] Example 2, PESA 18%, sodium gluconate 18%, methyl benzotriazole 1%, imidazoline 5%, deionized 58%.

[0031] Example 3, PESA 20%, sodium gluconate 22%, methyl benzotriazole 3%, imidazoline 5%, deionized 48%.

[0032] Example 4, PASP 25%, sodium gluconate 25%, methyl benzotriazole 4%, imidazoline 1%, deionized 45%.

[0033] 3. The ratio of ZT-305C: PASP or PESA 18-30%, sodium gluconate 18-30%, methyl benzotriazole 0.15-3%, imidazoline 1-5%, deionized water balance.

[0034] Example 1, PASP 20%, sodium gluconate 18%, methyl benzotriazole 0.15%, imidazoline 1%, deionized 58.85%.

[0035] Example 2, PESA 18%, sodium gluconate 20%, methyl benzotriazole 2%, imidazoline 3%, deionized 57%.

[0036] Example 3, PESA 25%, sodium gluconate 20%, methyl benzotriazole 3%, imidazoline 5%, deionized 47%.

[0037] Example 4, PASP 30%, sodium gluconate 25%, methyl benzotria...

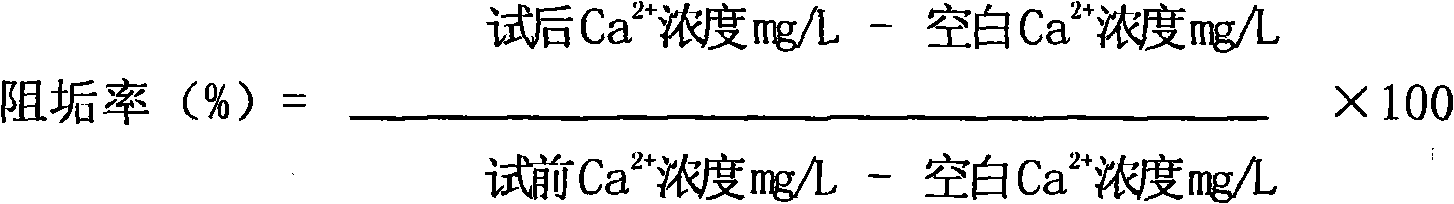

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com