High-strength recycled concrete and preparation method thereof

A recycled concrete, high-strength technology, applied in the field of building materials, can solve the problems of high water absorption, low compressive strength, and increased water consumption of recycled coarse aggregates, and achieves reduced porosity, improved wear resistance and compressive strength. , the effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

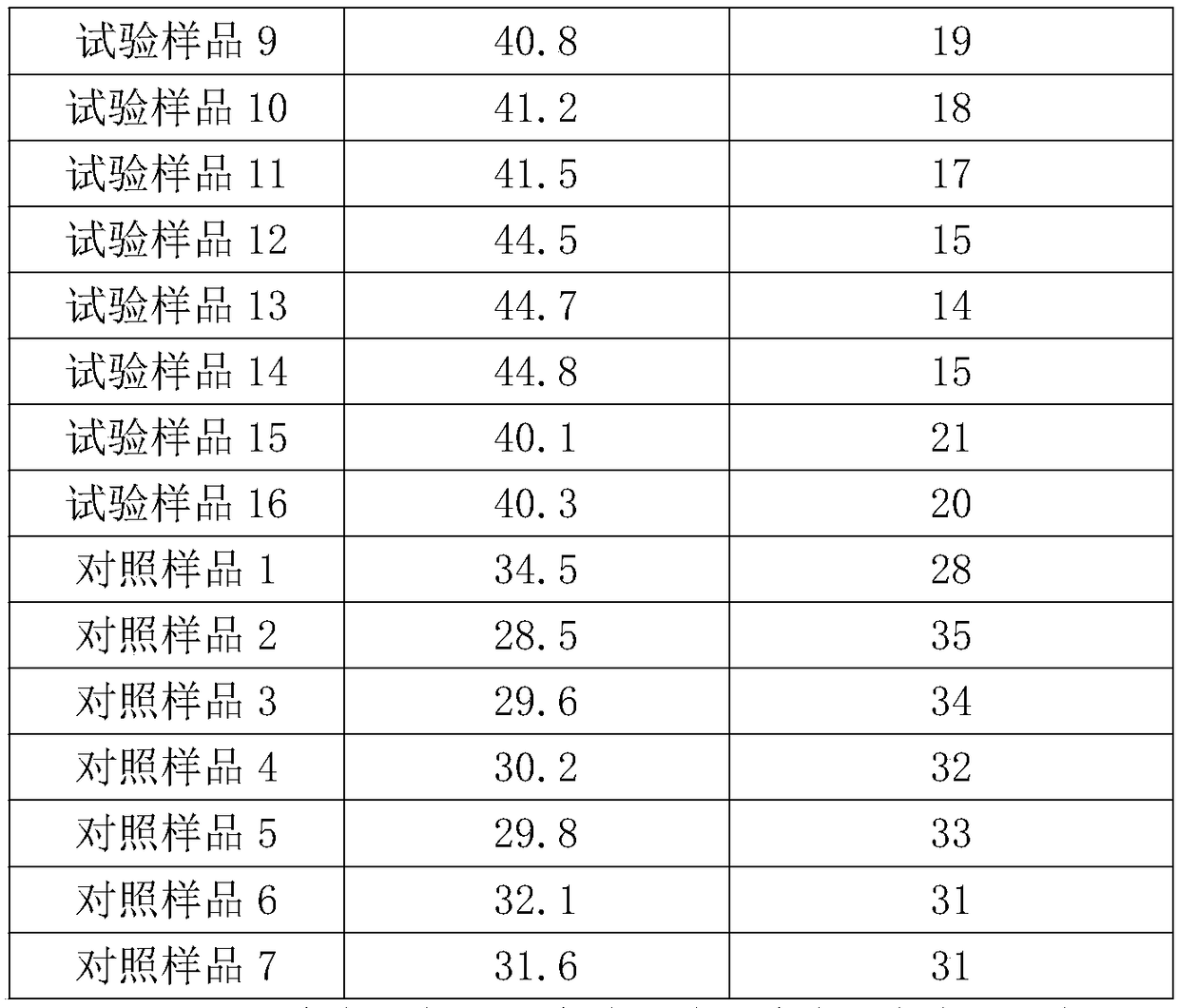

Examples

Embodiment 1

[0051] Embodiment 1: a kind of high-strength recycled concrete, its raw material comprises the component of following parts by weight:

[0052] Ordinary Portland cement 75 parts;

[0053] 60 parts of natural fine aggregate;

[0054] 90 parts of modified recycled coarse aggregate;

[0055] 8 parts of fly ash;

[0056]10 parts of microsilica fume;

[0057] 1 part of polycarboxylate superplasticizer;

[0058] Sodium gluconate 8 parts;

[0059] 5 parts of carbon nanofiber;

[0060] 8 parts of stainless steel fiber;

[0061] 35 parts of water;

[0062] The preparation method of modified recycled coarse aggregate is as follows:

[0063] (1) breaking the discarded concrete into aggregates of 5-40mm, then washing the broken aggregates with water, and drying them naturally to obtain dry aggregates, the moisture content of which is 2.5%;

[0064] (2) Mix penetrant, nano-titanium dioxide and water uniformly to form a modified liquid. The parts by weight of penetrant, nano-titani...

Embodiment 2

[0071] Embodiment 2: A kind of high-strength recycled concrete. The difference from Embodiment 1 is that the parts by weight of silica fume are 8 parts by weight, and the parts by weight of stainless steel fibers are 9 parts.

Embodiment 3

[0072] Embodiment 3: A high-strength recycled concrete. The difference from Embodiment 1 is that the weight parts of silica fume are 6 parts, and the weight parts of stainless steel fibers are 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com