Clay screening agent and preparation method thereof

A technology of shielding agent and clay, which is applied in the field of clay shielding agent and its preparation, can solve the problems of complex preparation conditions, etc., achieve the effects of wide sources, improved effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

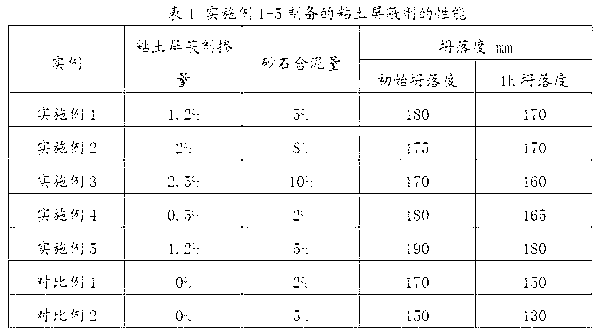

Examples

Embodiment 1

[0040] 1.1 The composition of the clay shielding agent is (g):

[0042] Sodium methyl silicate 25

[0043] Phosphate 0

[0044] Sodium Gluconate 1

[0045] Sodium Lauryl Sulfate 1

[0046] water 48

[0047] 1.2 Preparation method

[0048] (1) First, weigh the raw materials according to the weight ratio;

[0049] (2) The raw materials are then mixed and stirred at a temperature of 20° C., a stirring speed of 50 r / min, and a stirring time of 30 minutes to obtain a clay shielding agent.

Embodiment 2

[0051] 2.1 The composition of the clay shielding agent is (g):

[0052] Silicate 0

[0053] Disodium hydrogen phosphate 25

[0054] Sodium metaphosphate 25

[0055] Sodium Gluconate 5

[0056] Sodium Lauryl Sulfate 5

[0057] water 40

[0058] 2.2 Preparation method

[0059] (1) First, weigh the raw materials according to the weight ratio;

[0060] (2) The raw materials are then mixed and stirred at a temperature of 50° C., a stirring speed of 500 r / min, and a stirring time of 10 minutes to obtain the clay shielding agent.

Embodiment 3

[0062] 3.1 The composition of the clay shielding agent is (g):

[0063] Sodium silicate 10

[0064] Sodium methyl silicate 30

[0065] Disodium hydrogen phosphate 10

[0066] Sodium metaphosphate 10

[0067] Sodium Gluconate 5

[0068] Sodium Lauryl Sulfate 1

[0069] water 34

[0070] 3.2 Preparation method

[0071] (1) First, weigh the raw materials according to the weight ratio;

[0072] (2) Then the raw materials are mixed and stirred, the stirring temperature is 30°C, the stirring speed is 100r / min, and the stirring time is 15min, and the clay shielding agent can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com