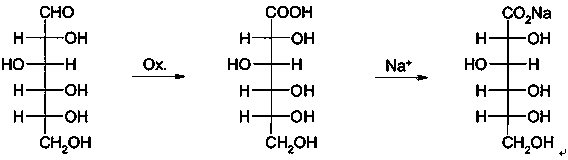

Novel low-sodium salt containing sodium gluconate and preparation method thereof

A sodium gluconate and low-sodium salt technology, applied in the field of edible salt, can solve problems such as threats to health, impact of application effects, inconsistent taste, etc., and achieve the effects of avoiding differences in salty taste, reasonable composition, and scientific and reasonable preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

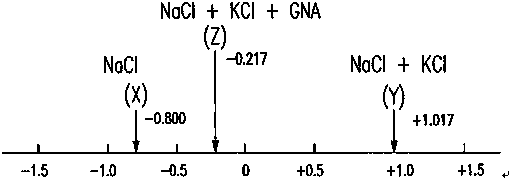

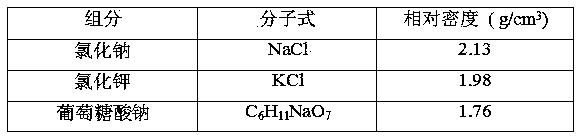

[0021] Prepare low-sodium salts in different proportions as shown in the table below, dissolve the prepared low-sodium salts in deionized water, and prepare a solution with a concentration of 3%. After tasting, the salty taste evaluation of each test sample is given. See the table below:

[0022]

Embodiment 2

[0024] On the batching basis shown in embodiment 1, determine following batching composition and content:

[0025] (1) 55 kg of food-grade sodium chloride, 25 kg of sodium gluconate, 18.5 kg of potassium chloride, and 1.5 kg of maltodextrin with a DE value of 15. Prepare a low-sodium salt sample according to the above ratio, put it into a V-type mixer and mix for 15 minutes, and take it out for inspection after thorough mixing. The code is sample A.

[0026] (2) Dissolve 55 kg of food-grade sodium chloride, 25 kg of sodium gluconate, and 18.5 kg of potassium chloride in 150 L of deionized water, raise the temperature to 85°C, stir continuously until completely dissolved, and prepare a dry matter concentration of 40% The solution. After the solution was cooled to 40°C, 1.5% maltodextrin with a DE value of 15 was added under stirring at a speed of 300 r / min, and spray-dried immediately after stirring at a speed of 300 r / min for 10 minutes. Drying with a centrifugal spray dryin...

Embodiment 3

[0035] Dissolve 55 kg of food-grade sodium chloride, 25 kg of sodium gluconate, and 18.5 kg of potassium chloride in 150 L of deionized water, raise the temperature to 85 °C, and stir continuously until completely dissolved, and prepare a solution with a dry matter concentration of 40%. After the solution was cooled to 40°C, 1.5% maltodextrin was added under stirring at a speed of 300 r / min, and spray-dried immediately after stirring at a speed of 300 r / min for 10 minutes. Dry with a centrifugal spray drying tower.

[0036] The spray drying parameters are set as follows: the inlet air temperature is 100°C, 150°C, 200°C. Air intake is set to 10 m 3 / h. The results are as follows:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com