Five-degree-of-freedom parallel-series bionic shoulder joint

A technology of degrees of freedom and bionic shoulder, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems that cannot be realized, the gap in the functional characteristics of the human shoulder joint, the structural form, and the low bionic level of kinematic characteristics, etc., to achieve a large working space, static The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

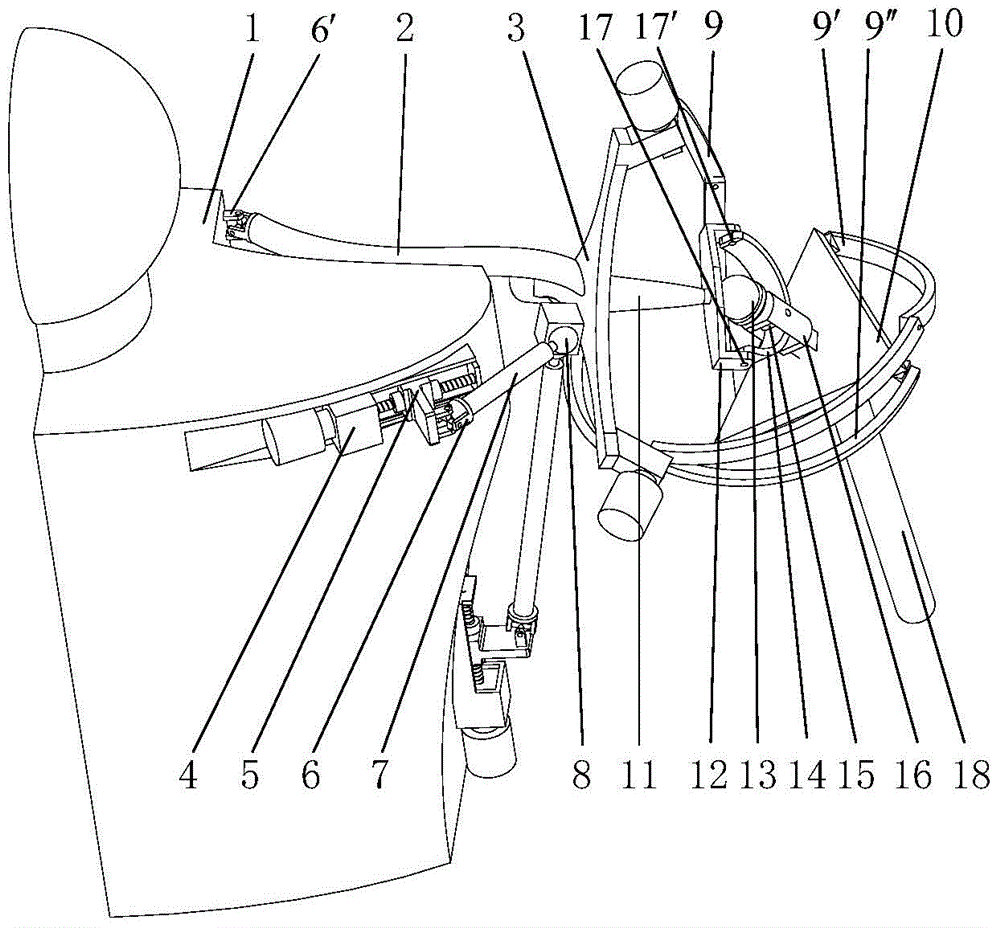

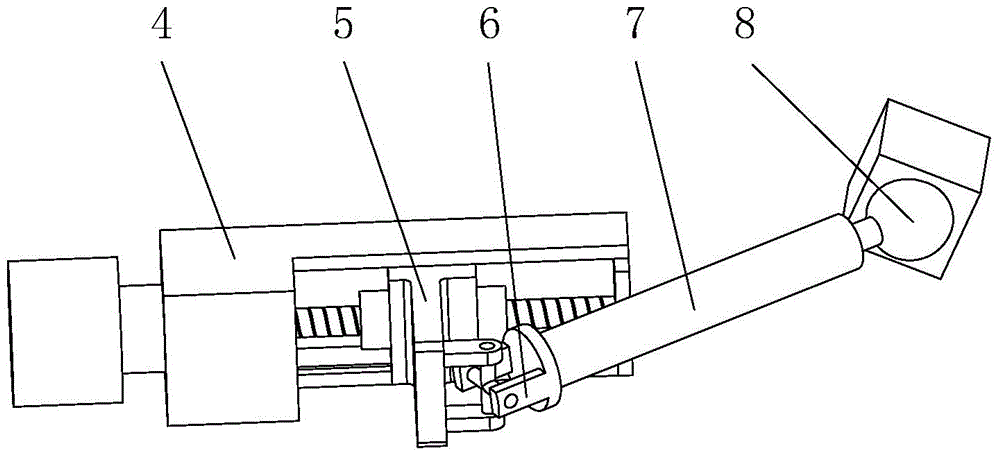

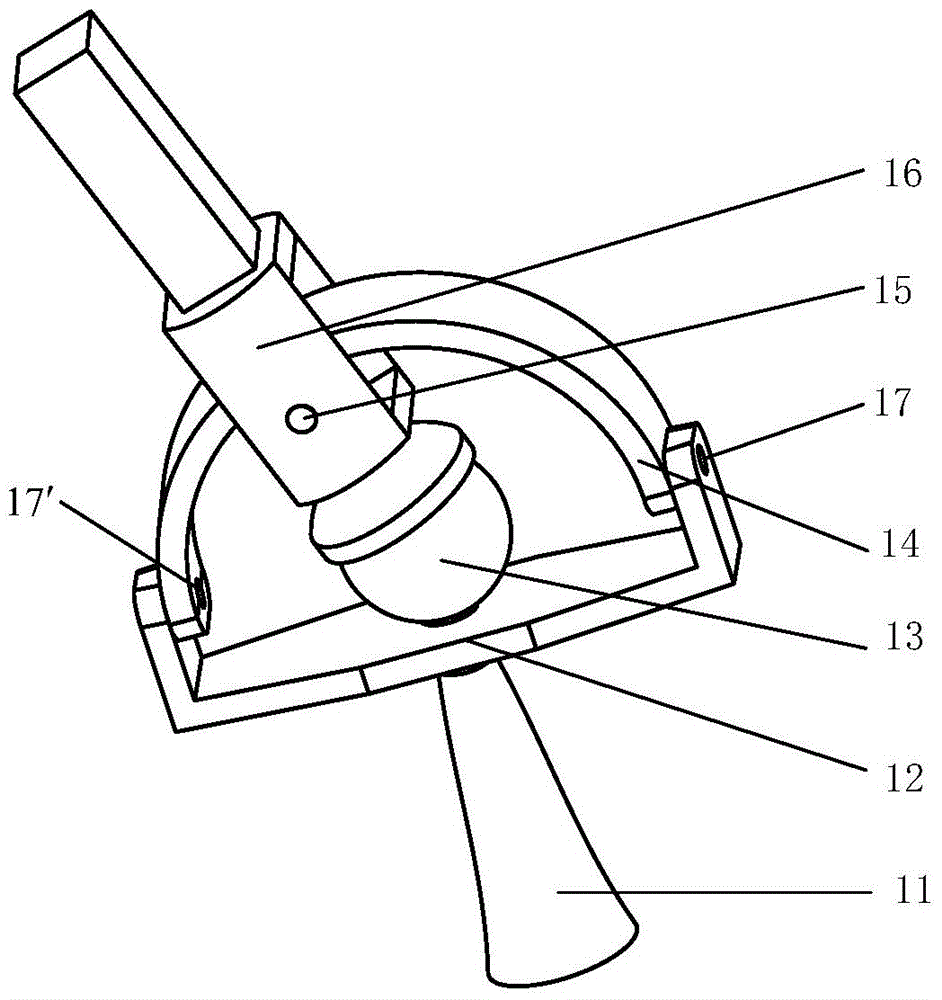

[0024] exist figure 1 In the schematic diagram of the five-degree-of-freedom parallel bionic shoulder joint shown in the figure, one end of the S-shaped connecting rod 2 in the 2-PUS+U two-degree-of-freedom parallel mechanism is connected to the bionic frame 1 through the Hooke hinge 6', and the other end is connected to the bionic frame 1. The middle moving platform 3 is fixedly connected; the horizontal motion branch chain and the vertical motion branch chain have the same structure, such as figure 2 As shown, the linear guide rail moving pair 4 of each motion branch chain is fixedly connected with the bionic frame, and the active slider 5 is set on the lead screw of the linear guide rail moving pair, and the active slider passes through the Hooke hinge 6 and the driven rod 7 The other end of the driven rod is connected with the intermediate moving platform through the spherical pair 8, the linear guide rail moving pair is the driving pair of the mechanism, the linear guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com