Cam roller negative stiffness structure low-frequency vibration isolator

A cam roller and negative stiffness technology, applied in the field of vibration reduction and vibration isolation, can solve the problems of inconvenient installation of low-frequency vibration isolators, poor adaptability to working conditions, complex structure, etc., to reduce impact, ensure synchronization, and improve applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

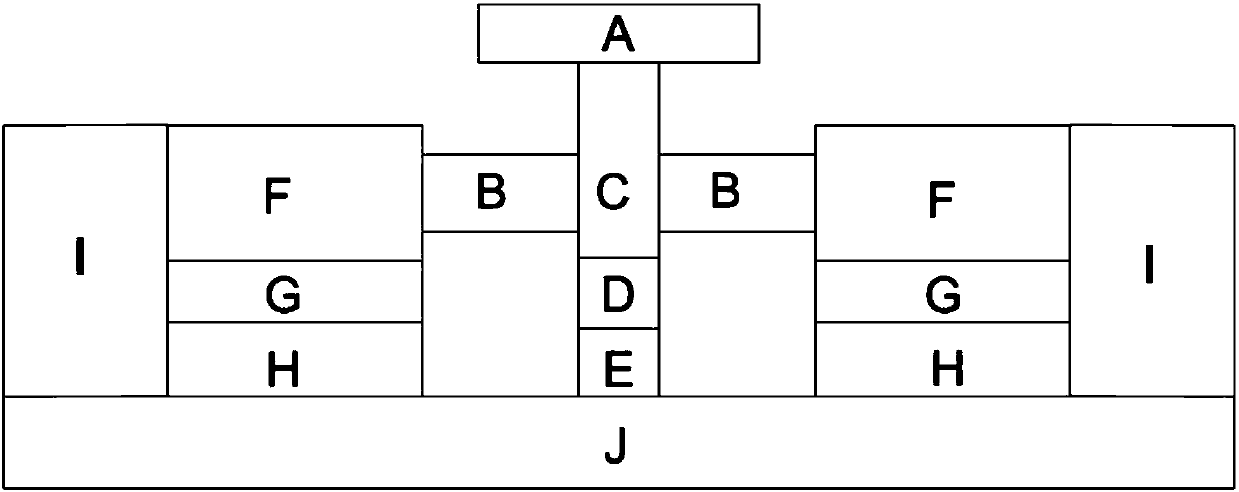

[0055] Such as figure 1 As shown, it is a structural block diagram of the system composition of a cam roller negative stiffness structure low-frequency vibration isolator of the present invention. Among them, the connection relationship of each component module is as follows:

[0056] The lower end of the center of the bearing device A is connected to the connecting cam C of the bearing platform, and the negative stiffness springs are connected to the cylindrical roller B on both sides of the connecting cam C of the bearing platform. The bottom connects and installs the positive stiffness spring D in the vertical direction and the positive stiffness spring positioning adjustment device E; the negative stiffness spring connects the cylindrical roller B with the negative stiffness spring structure F in the horizontal direction, and the negative stiffness spring structure F is connected with the negative stiffness spring positioning device G and The negative stiffness spring bot...

Embodiment 2

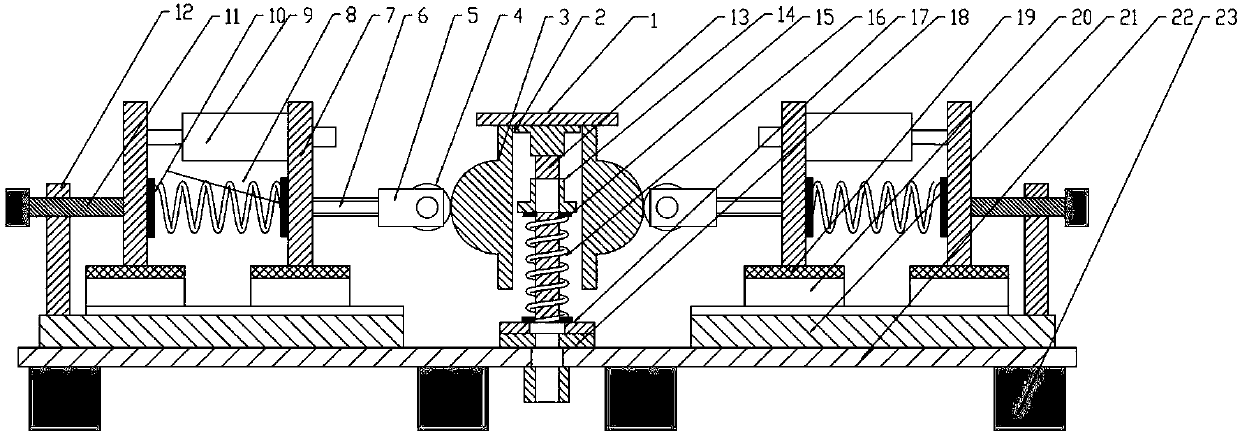

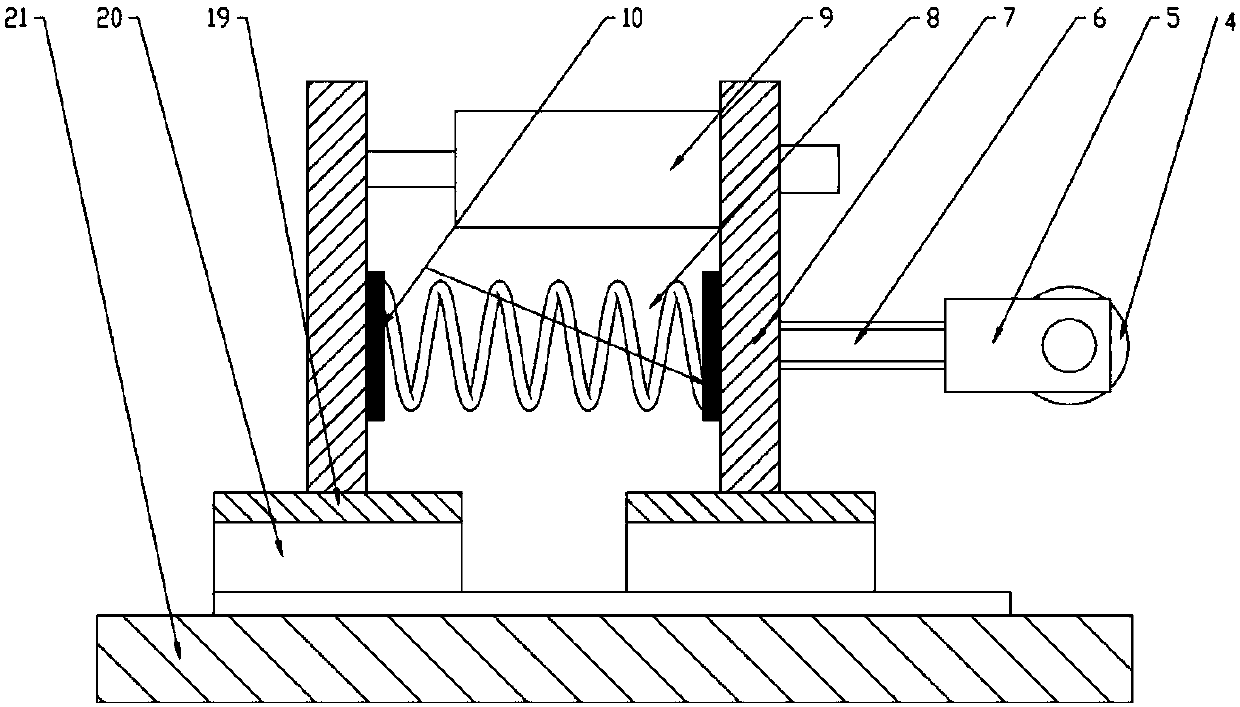

[0058] Such as Figure 2-5 shown; among them, figure 2 It is a structural schematic diagram of a low-frequency vibration isolator with a cam roller negative stiffness structure of the present invention; image 3 It is a structural schematic diagram of a negative stiffness structure in a cam roller negative stiffness structure low-frequency vibration isolator of the present invention; Figure 4 It is a structural schematic diagram of the connecting block of the horizontal spring bottom plate in a low-frequency vibration isolator with a cam roller negative stiffness structure of the present invention; Figure 5 It is a structural schematic diagram of a model bottom plate in a low-frequency vibration isolator with a cam roller negative stiffness structure of the present invention.

[0059] refer to figure 2 with image 3 , a cam roller negative stiffness structure low-frequency vibration isolator proposed in this embodiment includes a model base plate 22, and a model foot 2...

Embodiment 3

[0064] Figure 4 Shown is a structural schematic diagram of a cam roller negative stiffness structure low-frequency vibration isolator of this embodiment. The difference from Embodiment 2 is that the adjustment knob 11 for horizontal spring compression is adjusted. Adjusting the horizontal spring compression adjustment knob can realize the adjustment of the horizontal spring compression in the initial state, can change the negative stiffness value of the vibration isolator, and enhance the working condition adaptability of the vibration isolator.

[0065] Figure 5 It is the stiffness characteristic curve of a cam roller negative stiffness structure low-frequency vibration isolator of the present invention under different initial horizontal spring compressions. The parameter δ in the figure is the ratio of the horizontal spring compression to the sum of the radius of the cam and the cylindrical roller; x represents the displacement of the initial state; k represents the stif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com