Multifunctional solid wood processing device achieving milling and planing

A kind of processing equipment and multi-functional technology, which is applied in the direction of wood processing equipment, manufacturing tools, multi-purpose machinery, etc., can solve the problems of unsuitable solid wood processing, etc., and achieve the effect of improving rigidity, stable structure and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

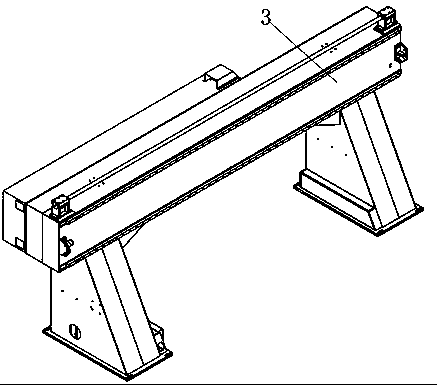

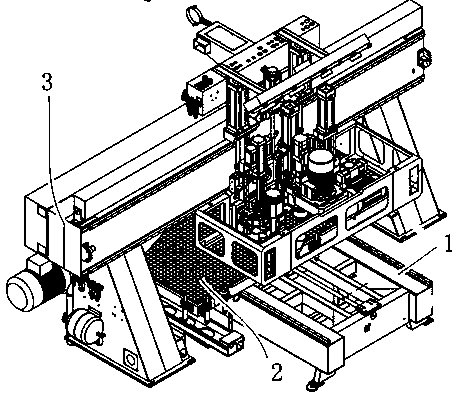

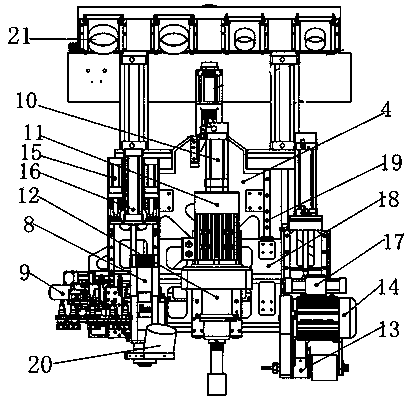

[0035] A multifunctional solid wood processing equipment for milling and planing, which is characterized in that it includes a base body, a workbench and a beam frame are fixed on the base body, and a slide plate is provided on the beam frame to slide freely along the direction of the beam frame , the slide plate is fixed with an engraving and milling module, a vertical axis milling module, and an indexable horizontal milling module. The engraving and milling module includes an engraving and milling spindle 8 and an engraving and milling tool magazine 9, wherein the engraving and milling tool magazine is a swing automatic tool changer. The engraving and milling spindle adopts a high-performance electric spindle, and the engraving and milling tool magazine supports ISO30 and ER32 tool loading to realize automatic tool change processing. The vertical axis milling module includes an end milling lifting cylinder 10 , an end milling spindle motor 11 and an end milling spindle 12 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com