Solid wood numerical control machining center and control system and machining method of solid wood numerical control machining center

A machining center, solid wood technology, applied in the field of CNC machine tools, can solve problems such as restricting the development of intelligent milling of CNC equipment, and achieve the effect of ensuring strength, smooth transmission, and precise speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

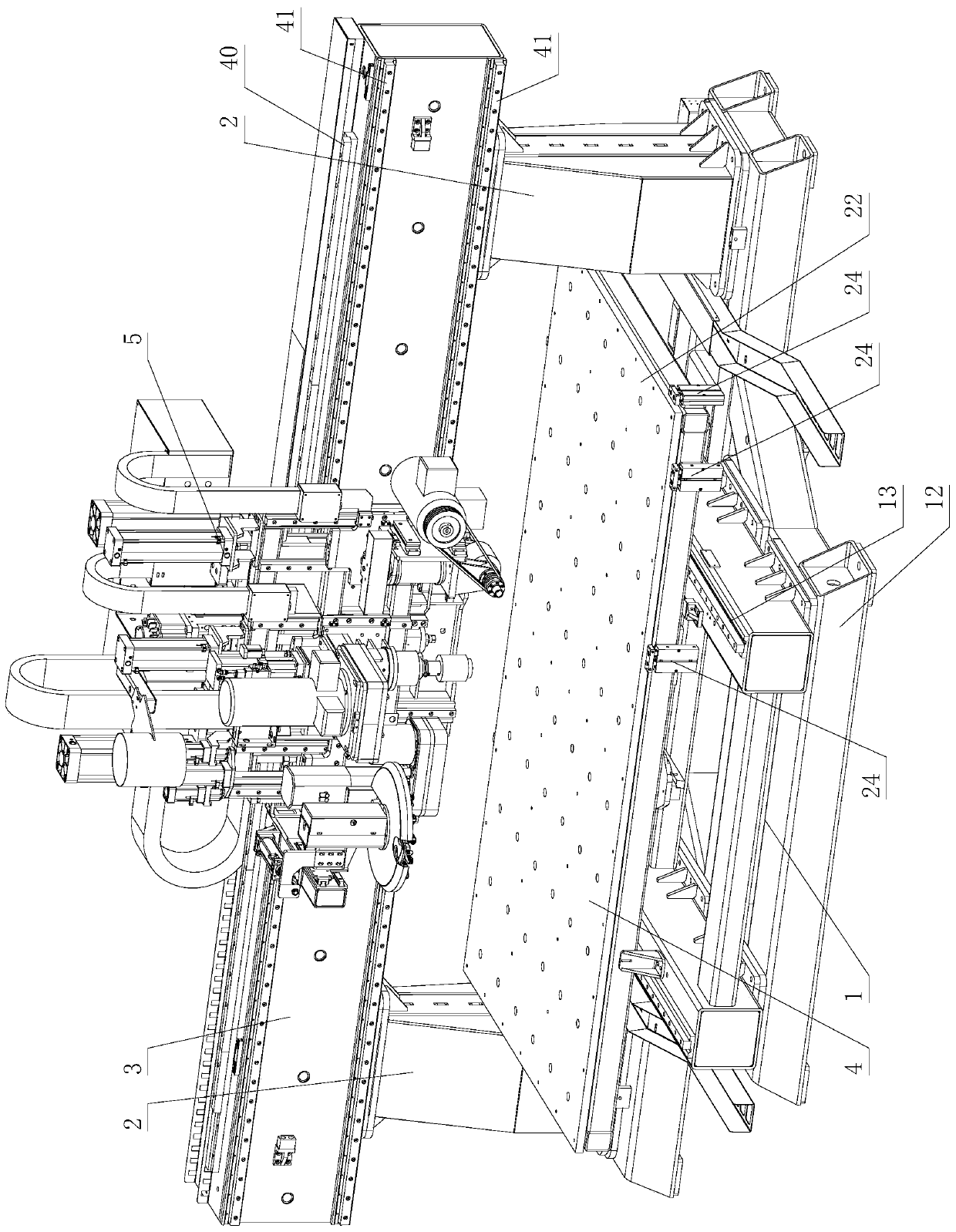

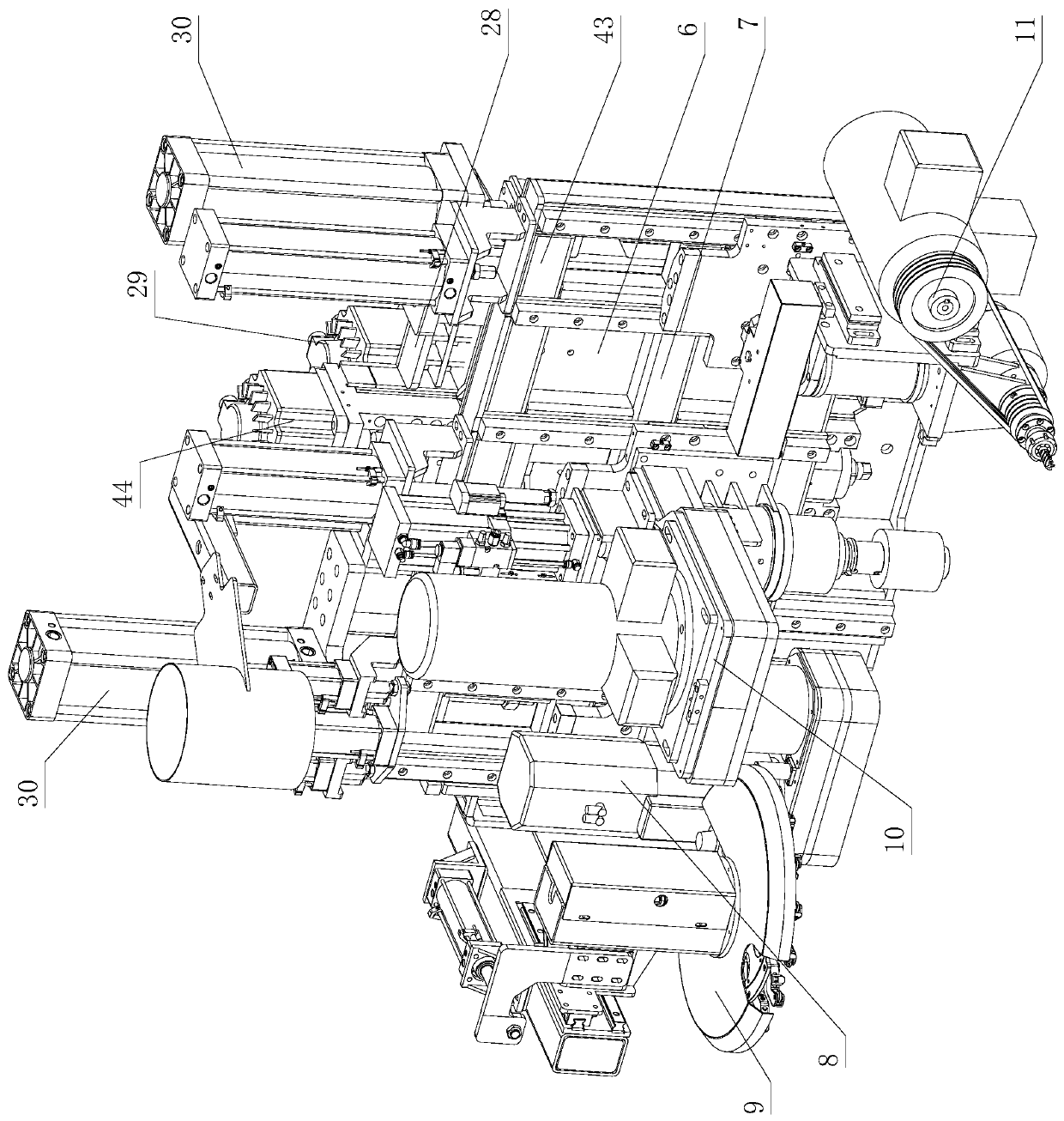

[0120] Such as figure 1 , image 3 , Figure 4 As shown, a solid wood CNC machining center includes a base 1, two columns 2 fixed on the left and right sides of the base 1 arranged in the X direction, and a beam 3 fixed on the two columns 2, which is installed on the base 1 and can be opposite to the base 1 The workbench device 4 that slides back and forth in the Y direction, the head device 5 that is installed on the beam 3 and can slide back and forth in the X direction relative to the beam 3; the head device 5 includes the X-direction slide assembly 6 and the Z-direction large slide assembly 7 , Routing and milling device 8, router device 9, vertical axis milling device 10, horizontal milling device 11.

[0121] Such as figure 1 As shown, the base 1 includes a lower base 12 and an upper base 13 .

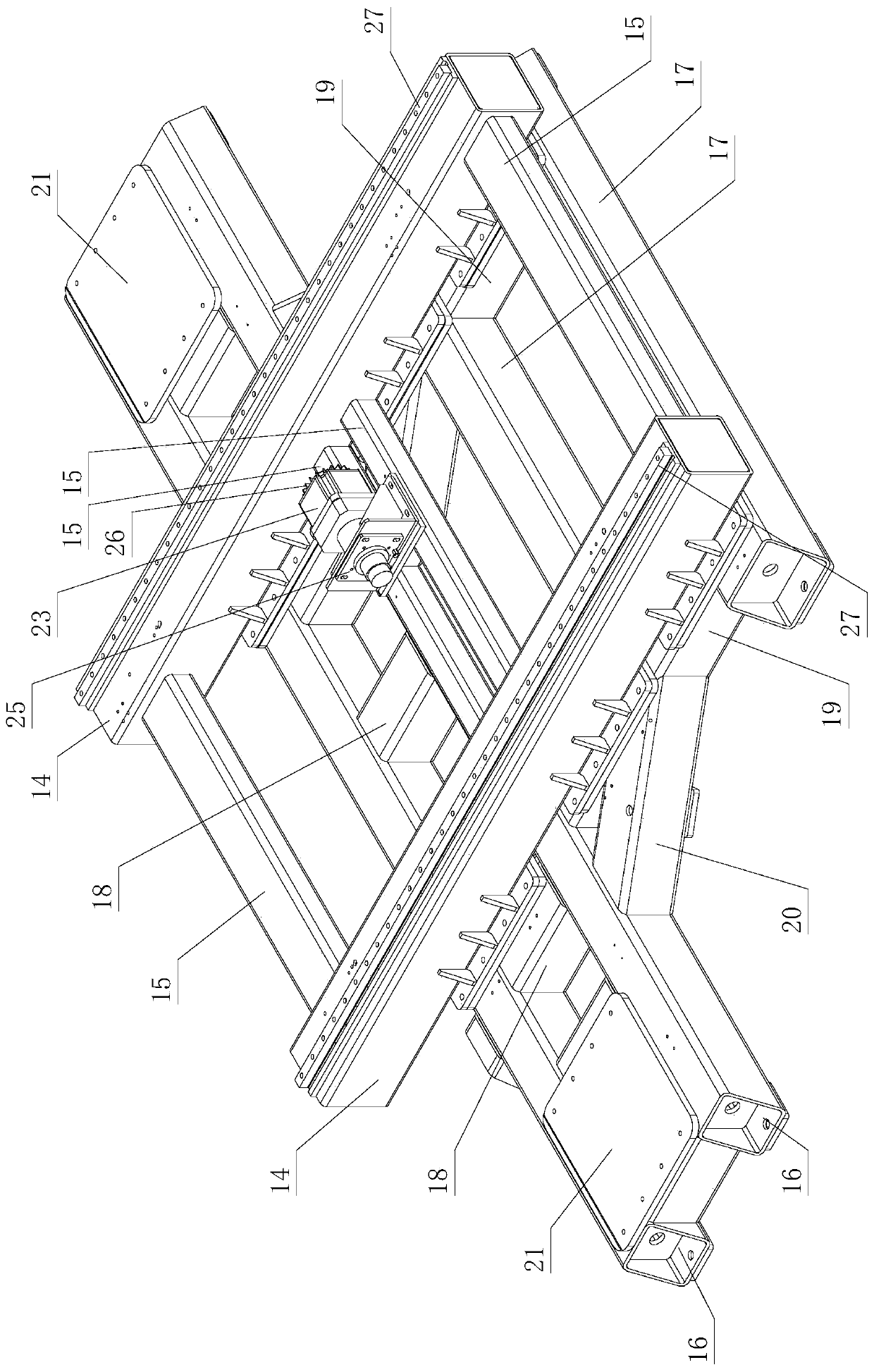

[0122] Such as figure 2 As shown, the upper base 13 includes two Y-direction large square tubes 14, four X-direction small square tubes 15 welded to connect the two Y-direc...

Embodiment 2

[0214] Such as Figure 13 to Figure 15 As shown, a control system of a CNC machining center includes a CNC controller, a data bus and a control bus connected to the CNC controller, a servo control unit connected in parallel with the data bus and the control bus for bidirectional control, a machine head control unit, and a working Station control unit, strong and weak current control unit, man-machine dialogue interface unit, communication unit.

[0215] The servo control unit includes the Y-axis feed servo system that drives the table to slide back and forth along the base in the Y direction, drives the X-axis feed servo system that drives the X-direction slide seat to slide back and forth along the beam in the X direction, and drives the Z-direction large slide seat to slide relative to the X direction. The Z-axis feed servo system that slides back and forth in the Z direction; the P-axis feed servo system that drives the cutter head with multiple clamping mechanisms to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com