Ultralow-frequency hydraulic-pressure vibration isolation device based on shape memory alloy spring

A memory alloy spring and hydraulic technology, which is applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve the problem of high rigidity of elastic elements, difficulty in achieving ultra-low frequency vibration isolation, and difficulty in dealing with ultra-low frequency vibration and noise, etc. problem, to achieve the effect of isolating ultra-low frequency vibration and low frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

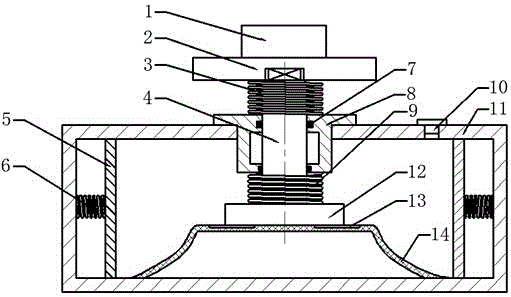

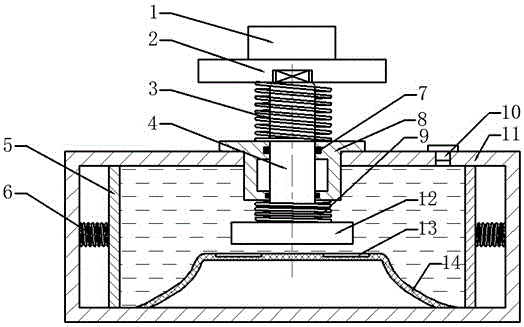

[0023] The design idea of the present invention is illustrated below by accompanying drawings.

[0024] Such as figure 1 As shown, in the present embodiment, the box body 11 has a built-in hollow elastic rubber support body 14, and the rubber support body 14 is provided with an oil guide groove 13, and a movable plate 5 is respectively arranged on the left and right sides of the box body 11, and the movable plate 5 and the inner wall of the box body 11 A spring 6 is arranged between them, a round hole is opened in the center of the upper cover plate of the box body 11, and the guide sleeve 8 is installed in the round hole, and is fixedly connected with the upper cover plate of the box body 11 by bolts, the piston rod 4 passes through the guide sleeve 8, and passes through the The seal 7 seals. The upper end of the piston rod 4 is threadedly connected with the mounting table 2, and the lower end is connected with the piston 12. Moreover, a shape memory alloy spring 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com