Quasi-zero rigidity inertia actuator

A quasi-zero stiffness, actuator technology, applied in the field of inertial actuators, can solve the problems of inability to reach low frequency or even ultra-low frequency, small actuator output, excessive actuator volume and current intensity, etc., to achieve increased The effect of low frequency or even ultra low frequency output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

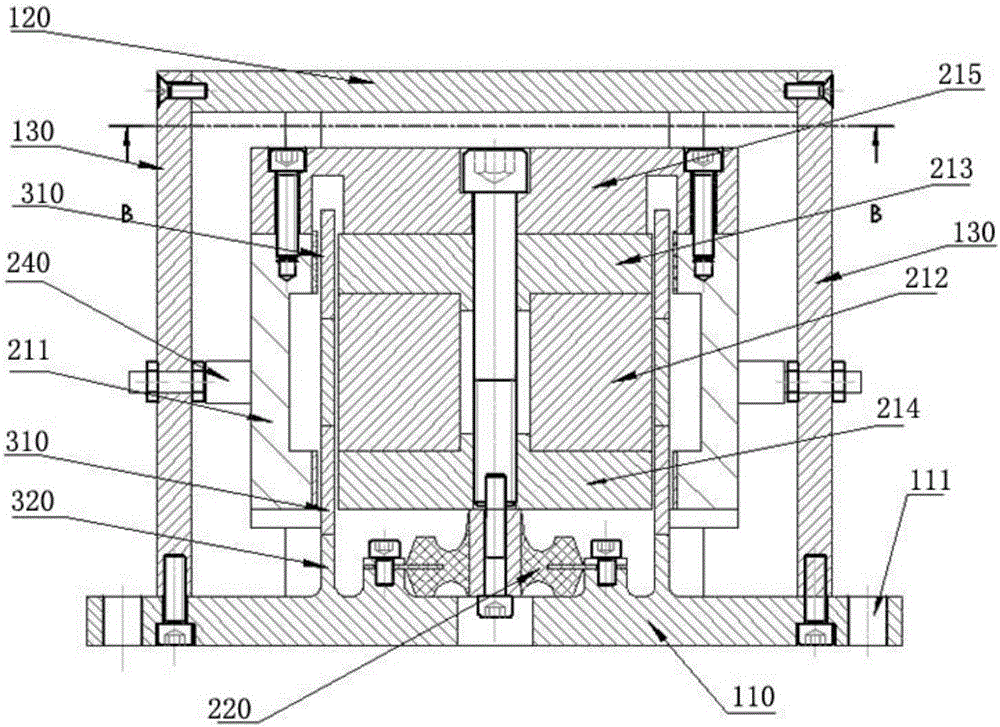

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following is a preferred embodiment for illustrating the present invention, but not intended to limit the scope of the present invention.

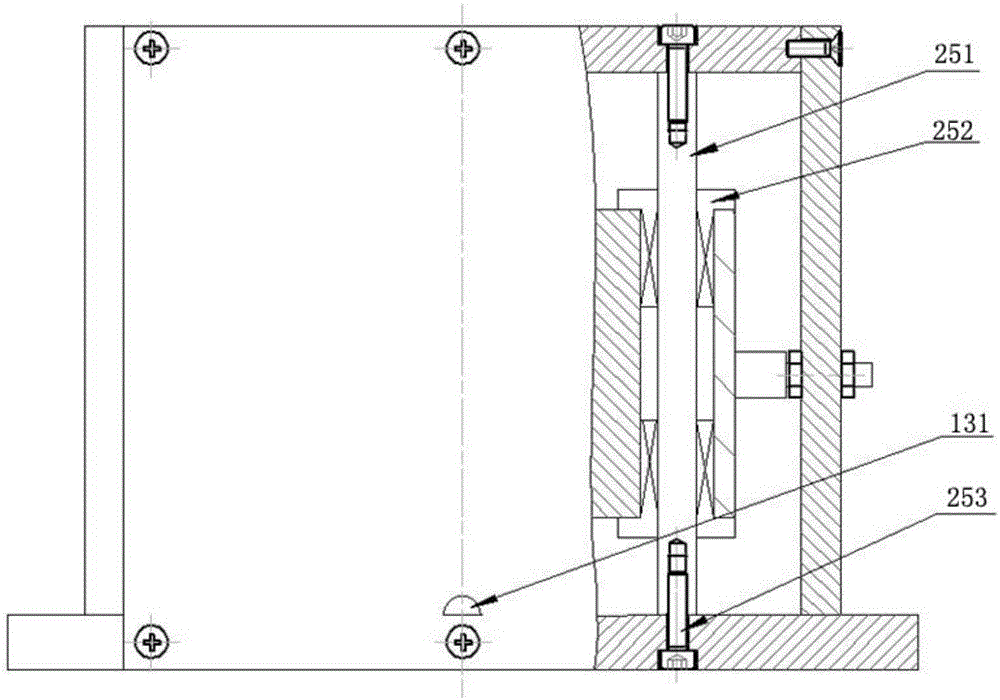

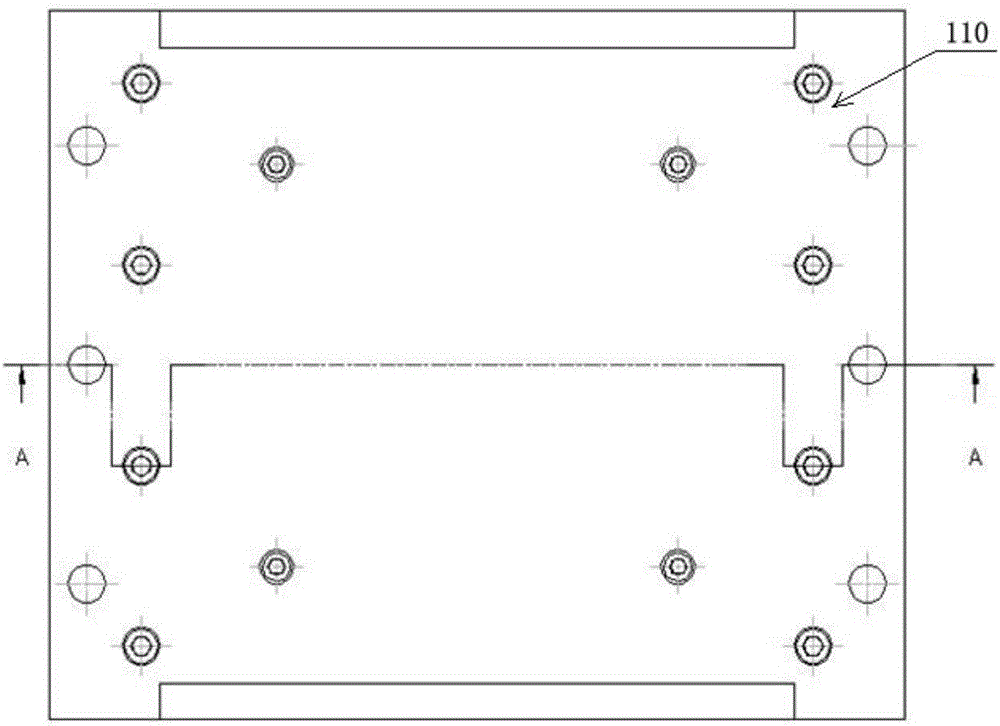

[0028] see Figure 1 to Figure 6 , as shown in the legend there:

[0029] A quasi-zero stiffness inertial actuator comprising:

[0030] -The housing, which includes a base 110, an upper end cover 120 and a side wall 130, the base 110 is provided with a connection hole 111 connected to the controlled device, and the side wall 130 is respectively provided with a first interface 131 and a second interface 132;

[0031] - a movable assembly comprising a movable part, a first support part, a second support part and a guide part,

[0032] --Above-mentioned moving part comprises magnetic cylinder 211, is arranged on the permanent magnet 212 in the magnetic cylinder 211,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com