Template laser cutting equipment provided with template fixture

A technology of laser template and cutting equipment, used in laser welding equipment, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of heavy equipment, inability to complete, large size, etc., to achieve short operation time, maintain stability, production Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

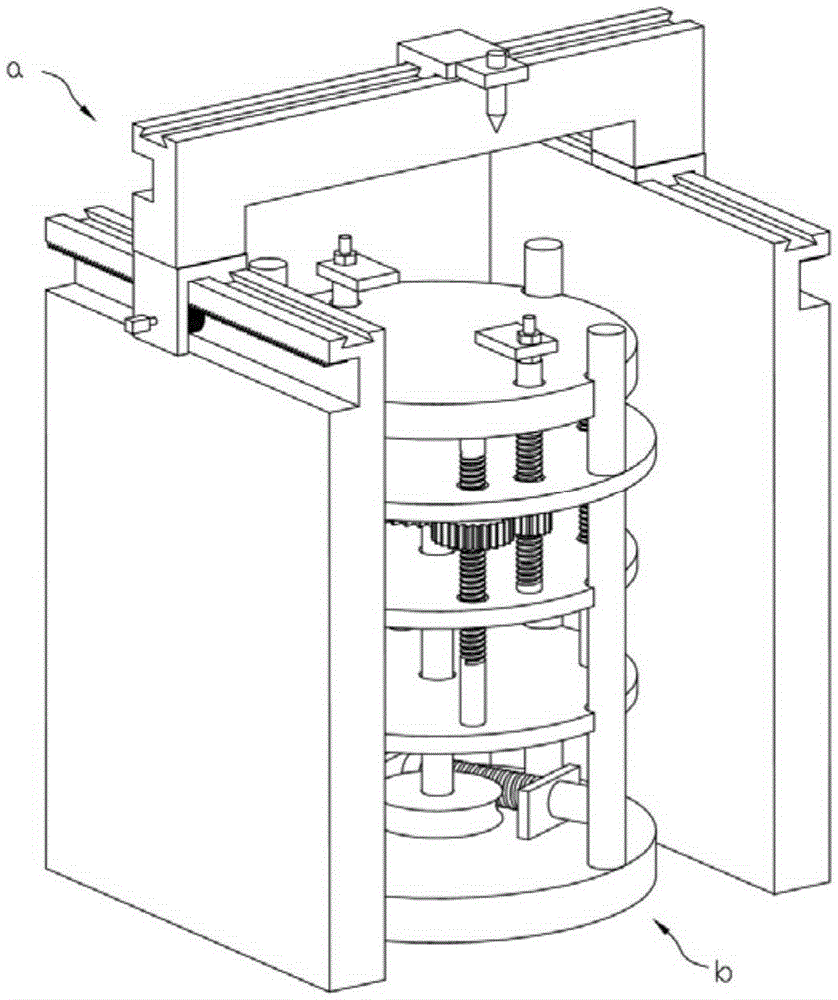

[0037] like figure 1 What is claimed is a laser template cutting device provided with a template clamp, comprising a cutting mechanism a and a template clamp b.

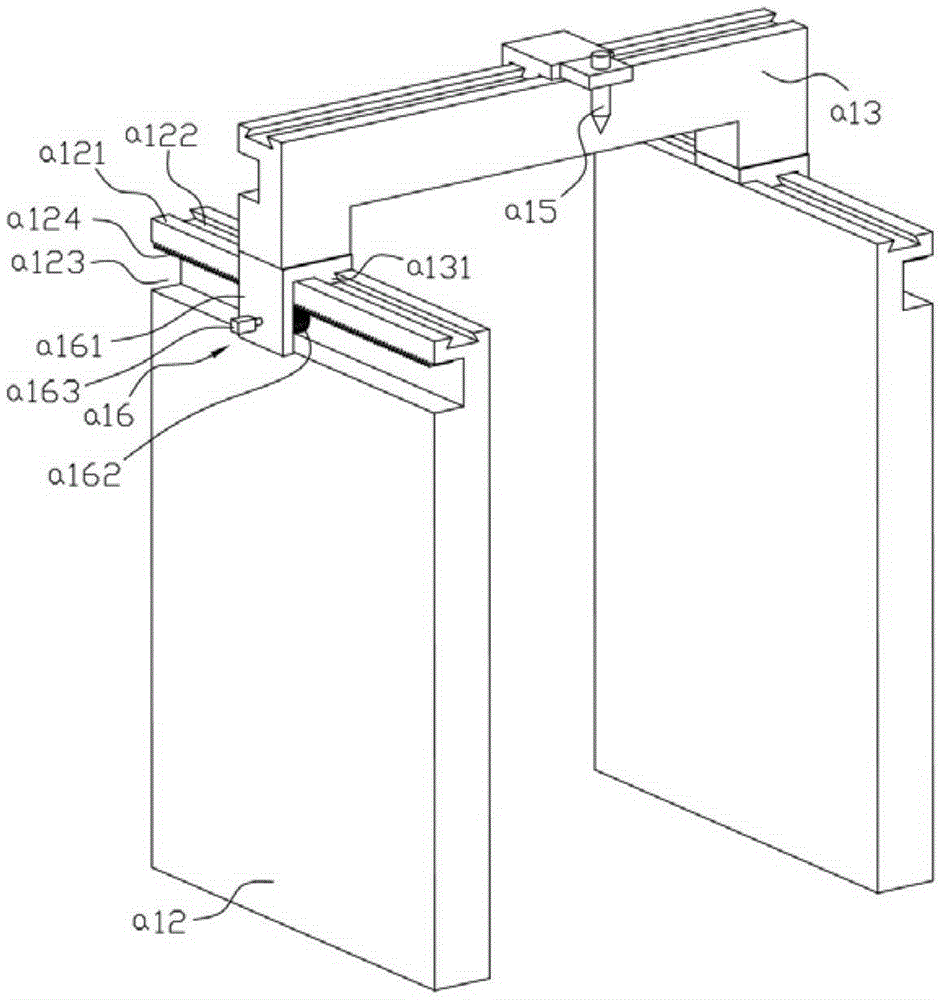

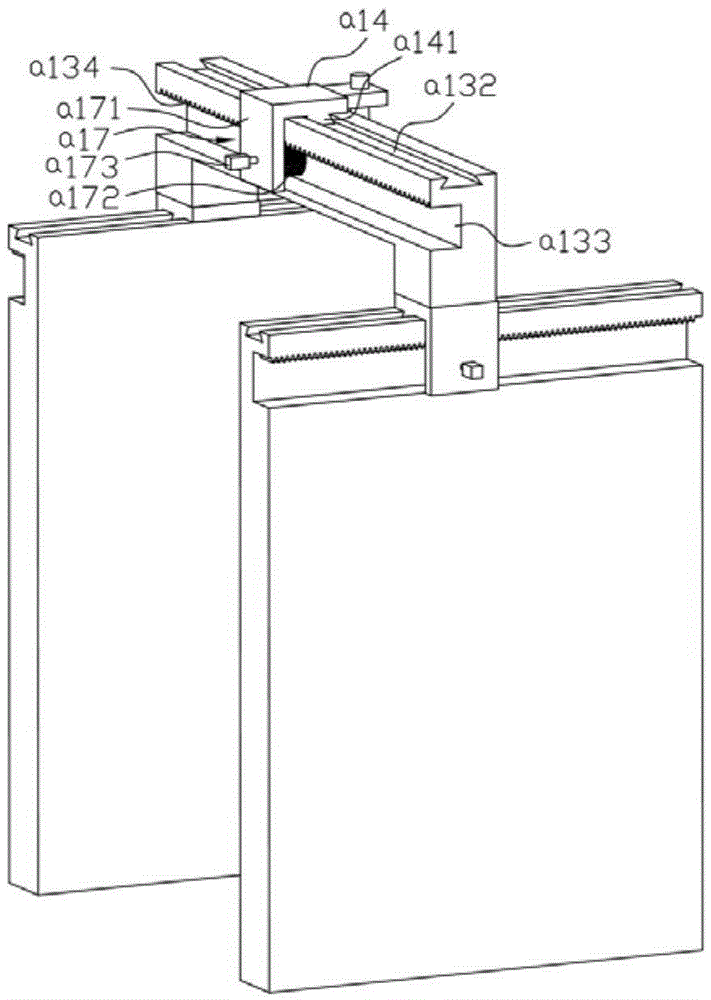

[0038] to combine figure 2 , image 3 , the cutting mechanism a includes a pair of left and right frame plates a12, a beam a13 across the pair of frame plates, a laser frame a14 installed on the beam, and a laser head a15 installed on the laser frame; the pair A Y-direction slideway is provided on the frame plate, and an X-direction slideway is provided on the beam. On the X-direction slideway of the beam; the laser head is connected with the laser generator through the reflection device.

[0039] In the above-mentioned cutting mechanism a, the pair of frame plates a12 includes a left frame plate and a right frame plate, a first Y-direction slideway a121 is provided on the left frame plate, and a first Y-direction slideway a121 is provided on the right frame plate. Two Y-direction slideways; the first Y-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com