Cutter assembly and garbage granulator

A granulator and cutter technology, which is applied in the direction of raw material extrusion granulation, metal processing, plastic recycling, etc., can solve the problem that the blade cannot meet the requirements of high-quality garbage granulation, and achieve good granulation effect and increase The effect of cutting area and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

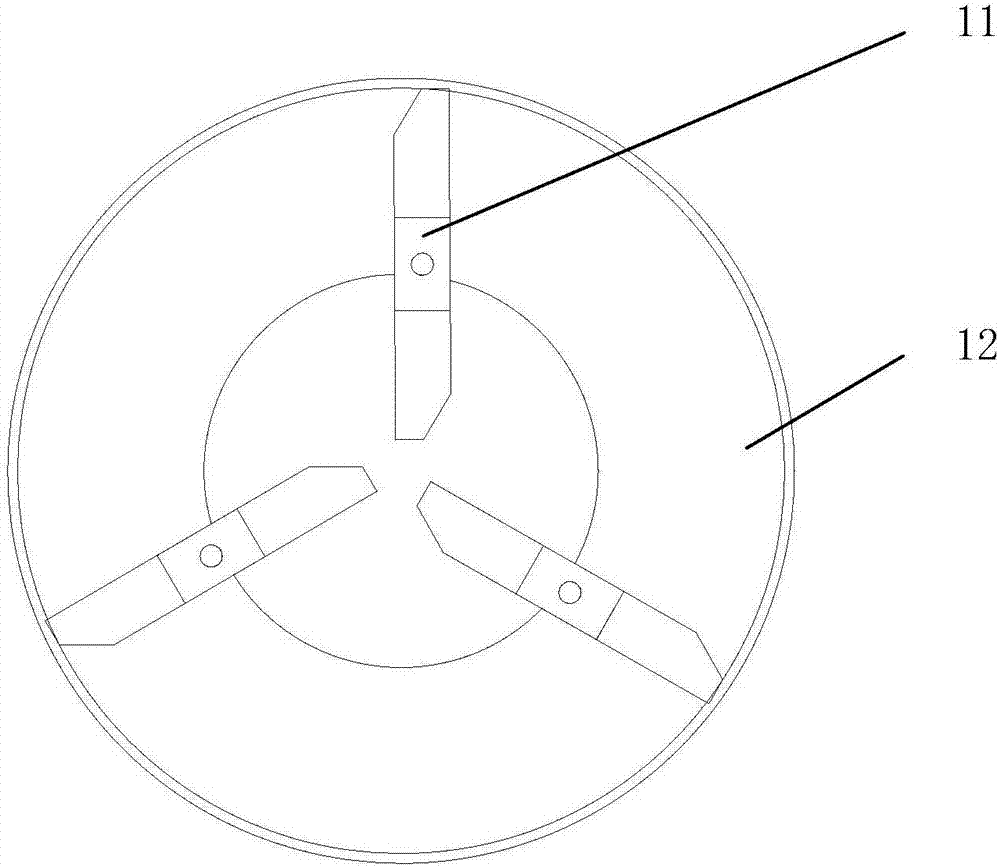

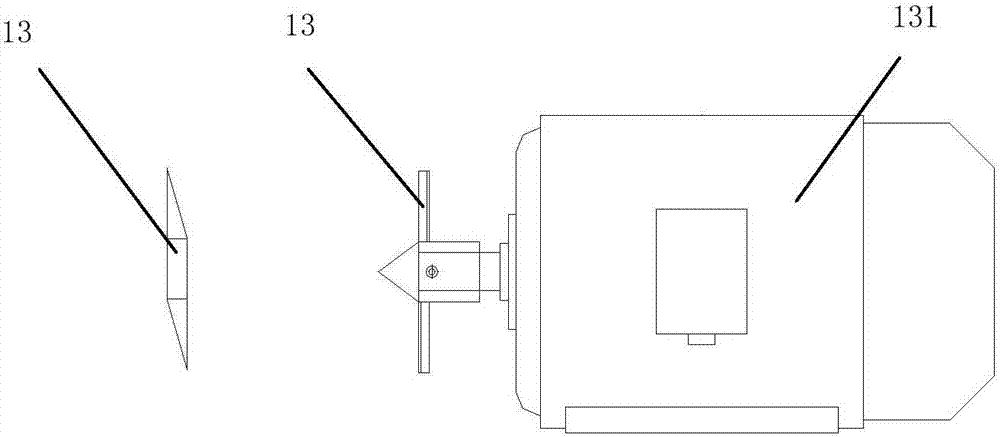

[0028] The present embodiment provides a cutter assembly 1, comprising: a plurality of cutting blades 11, a cutter seat 12, and a driving device; The cross-section is evenly distributed in the circumferential direction, and each cutting blade 11 is respectively connected to a driving device, and the driving device drives the cutting blade 11 to rotate relative to the cutter seat 12.

[0029] Wherein the material cutting blade 11 is hinged on the cutting knife seat 12, and the driving device drives the material cutting blade 11 to be able to rotate relative to the cutting knife seat 12, and the rotating surface formed by the material cutting blade 11 rotation is parallel to the cutting material section, and along with the feeding of the cutting material, The cutting blade 11 in rotation can realize the function of cutting. The cutting blades 11 distributed along the axial direction of the cross-section of the hollow structure cooperate with each other to increase the cutting ar...

Embodiment 2

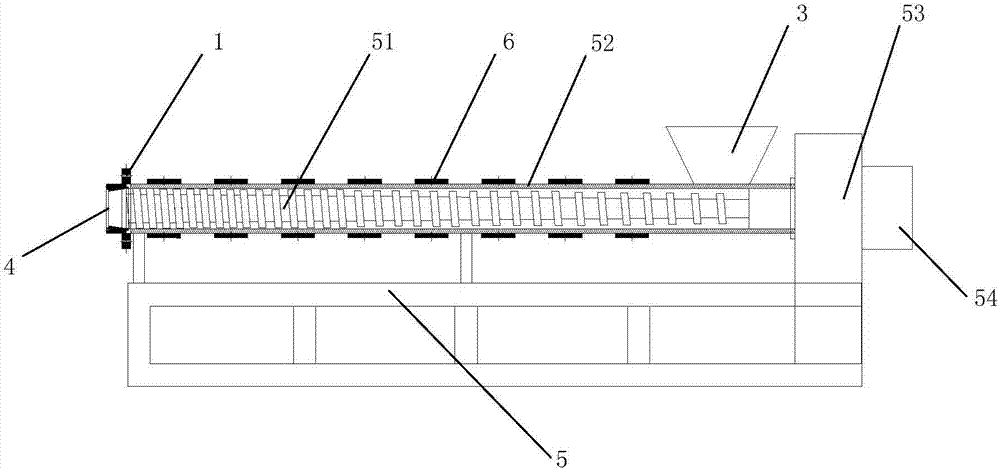

[0045] With reference to the body 3, the embodiment of the present invention provides a garbage granulator, including a material preparation device, the material preparation device has a feed port 3 and a discharge port 4, and an extruding device is arranged between the feed port 3 and the discharge port 4 Mechanism, the outlet 4 is provided with any kind of cutter assembly 1 as provided in Embodiment 1.

[0046] Most of the existing domestic waste is plastic waste, and many wastes need to be pretreated before burning the waste. In the process of garbage pretreatment, it is necessary to squeeze and pelletize the garbage to form garbage pellets, which is convenient for subsequent treatment such as garbage incineration.

[0047] Wherein, the extruding mechanism is arranged horizontally, and the feeding port 3 is arranged at one end of the extruding mechanism. The feed port 3 is funnel-shaped, the upper end of which is open to receive the material conveyed from the upstream, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com