Wear-resisting hammer head for hammer type breaking machine and production method of wear-resisting hammer head

A hammer crusher and hammer head technology, which is applied in the field of crushers, can solve the problems that restrict the stable operation of the production line, cannot meet the feeding requirements, and the uneven texture of the material, so as to ensure good combination, high hardness and wear resistance, The effect of removing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The invention provides a wear-resistant hammer head for a hammer crusher, which includes a high manganese steel lifting lug and a high chromium cast iron hammer head body.

[0047] The specific production method is:

[0048] (1) Melting:

[0049] Put high-carbon ferrochromium, ferromolybdenum FeMo60, nickel plate, pig iron and steel scrap into a 250Kg medium-frequency induction furnace for melting, and control the melting temperature at 1450°C; add aluminum for deep deoxidation and perform degassing and inclusion removal treatment

[0050] (2) Deterioration treatment:

[0051] The molten iron in step (1) is tapped at a high temperature, and the tapping temperature is controlled at 1480°C, and Ti, Nb, Ce and La are added for modification during tapping, so as to ensure the percentage of the metamorphic component in the total mass of the molten iron 0-0.2%;

[0052] (3) Pouring:

[0053] Pre-cast high-manganese steel lifting lugs, and remove surface impurities on the ...

Embodiment 2

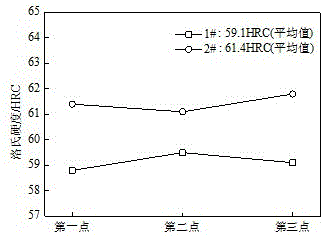

[0067] Adjust the chemical composition of the hammer body, as shown in Table 5, and increase the quenching temperature to 1050° C., the tempering temperature to 400° C., and the tempering time to 3 hours during the heat treatment in step (4).

[0068] Table 5: The chemical composition list of hammerhead body in embodiment 2:

[0069] Element C Cr Si mn Mo Cu Ni V Ti, Nb, Re before spoilage 2.74 19.14 0.98 0.74 1.08 0.64 0.82 0.13 trace After spoilage 2.42 18.98 0.79 0.78 1.11 0.58 0.83 0.25 trace

[0070] Table 6: Carbon equivalent and carbide volume fraction of the hammerhead body in Example 2:

[0071] model C eq / % cast iron type Carbide volume fraction / % before spoilage 3.77 hypoeutectic 30.90 After spoilage 3.68 hypoeutectic 28.91

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com