A kind of copper alloy material and preparation method thereof

A drug-type mask and copper alloy technology, which is applied in the field of metal materials, can solve the problems of the mismatch between the diameter of the reaming hole and the penetration depth, and the lack of research on the impact of reaming, so as to improve the uniformity and performance consistency and improve the purity. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

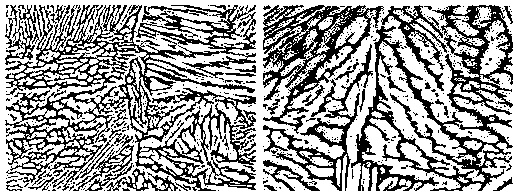

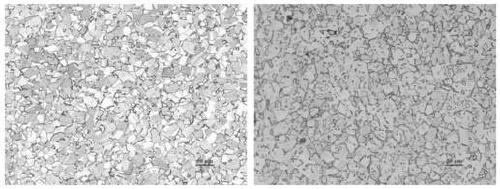

Image

Examples

Embodiment 1

[0033] (1) Powder preparation: Commercial electrolytic copper powder (650 mesh), zinc powder (325 mesh) and aluminum powder (200 mesh) are used, and the powder purity reaches 99.9%.

[0034] (2) Powder mixing and compacting: According to a certain composition ratio (mass fraction, as shown in Table 1), the three powders are evenly mixed, and pressed to produce a billet with a specification of φ90×500mm.

[0035] Table 1 Copper alloy powder composition ratio (wt.%)

[0036] powder name copper powder Zinc powder Aluminum powder Remark quality score 68% 20% 12%

[0037] (3) Pre-sintering: use a nitrogen atmosphere to protect the furnace, sinter at 520 ° C for 2 hours, and then cool to 80 ° C with the furnace to obtain a prefabricated billet with a certain strength.

[0038] (4) Vacuum electron beam smelting: the prefabricated billet in step (3) is purified and homogenized by vacuum secondary electron beam smelting, and the vacuum degree of the sme...

Embodiment 2

[0047] (1) Powder preparation: Commercial electrolytic copper powder (800 mesh), zinc powder (400 mesh), and aluminum powder (270 mesh) are used, and the powder purity reaches 99.9%.

[0048] (2) Powder mixing and compacting: According to a certain composition ratio (mass fraction, as shown in Table 3), the three powders are mixed evenly, and pressed to produce a billet with a specification of φ100×500mm.

[0049] Table 3 Copper alloy powder composition ratio (wt.%)

[0050] powder name copper powder Zinc powder Aluminum powder Remark quality score 65% 25% 10%

[0051] (3) Pre-sintering: Use a nitrogen atmosphere to protect the furnace, sinter at 500°C for 2 hours, and then cool to 80°C with the furnace to obtain a prefabricated billet with a certain strength.

[0052] (4) Vacuum electron beam smelting: the prefabricated billet in step (3) is purified and homogenized by vacuum secondary electron beam smelting, and the vacuum degree of the smelt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com