Composite molybdenum wire for wire cutting and production method thereof

A manufacturing method and technology for compounding molybdenum, which are applied in manufacturing tools, electrode manufacturing, metal processing equipment, etc., can solve the problems of abnormal wire breakage of wire cutting molybdenum wire, uneven use effect, low strength of pure molybdenum wire, etc. Abnormal wire breakage, improved A rate, good diameter uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Doping 0-3000ppm La in molybdenum powder 2 o 3 .

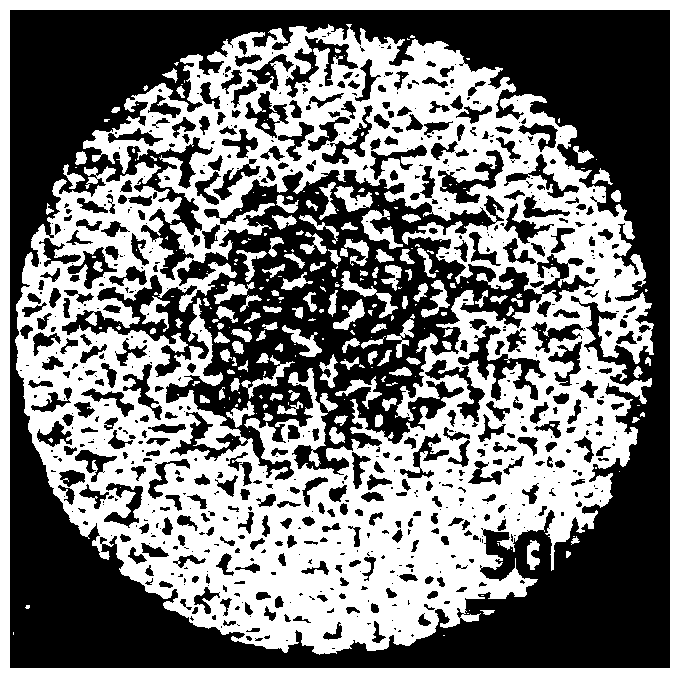

[0034] Solid-liquid doping is carried out in the molybdenum dioxide stage, doped with 0-3000ppm La 2 o 3 . The raw material ammonium molybdate is calcined at 400°C to obtain molybdenum trioxide, the molybdenum trioxide is reduced by hydrogen to obtain molybdenum dioxide, and the solid-liquid doping is carried out by solid molybdenum dioxide and liquid lanthanum nitrate to obtain a compound containing La 2 o 3 The doped molybdenum dioxide is then reduced by hydrogen to obtain the doped molybdenum powder containing lanthanum oxide. Finally, the doped molybdenum powder is mixed with a three-dimensional mixer and mixed uniformly; the particle size of the doped molybdenum powder is controlled at 3.0μm; put the doped molybdenum powder into the rubber sleeve, press it into a Φ50mm molybdenum billet by isostatic pressing, the molding pressure is 150MPa, the pressure holding time is 120 seconds, and then sinte...

Embodiment 2

[0035] Embodiment 2: Doping 100ppm~3000ppm Co and 1200ppm La in molybdenum powder 2 o 3 .

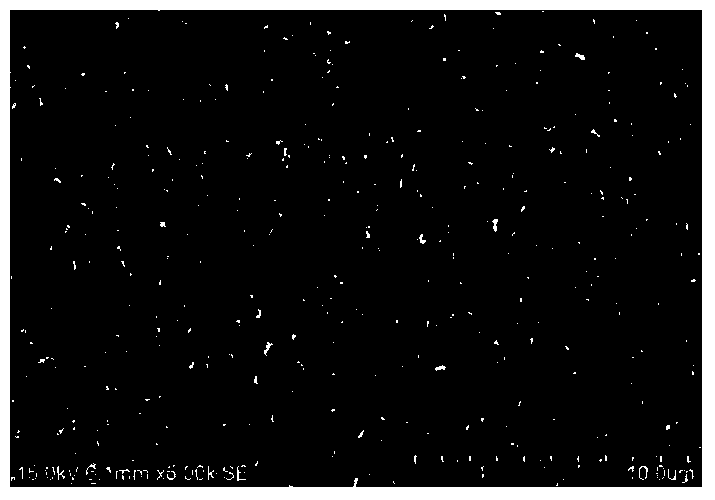

[0036] Solid-liquid doping in molybdenum dioxide stage, doping 100ppm ~ 3000ppm Co and 1200ppm La 2 o 3 . The raw material ammonium molybdate is calcined at 400°C to obtain molybdenum trioxide, the molybdenum trioxide is reduced by hydrogen to obtain molybdenum dioxide, and solid-liquid doping is carried out by solid molybdenum dioxide and liquid lanthanum nitrate to obtain a 2 o 3 Doped molybdenum dioxide, which is then reduced by hydrogen to obtain doped molybdenum powder containing lanthanum oxide, solid-liquid doping is performed again by using solid molybdenum powder doped with lanthanum oxide and liquid cobalt nitrate to dope cobalt, Then, the molybdenum powder that has been mixed with lanthanum oxide and cobalt is reduced by hydrogen again to obtain molybdenum powder doped with lanthanum oxide and cobalt. Finally, the molybdenum powder is mixed by a three-dimensional mixer t...

Embodiment 3

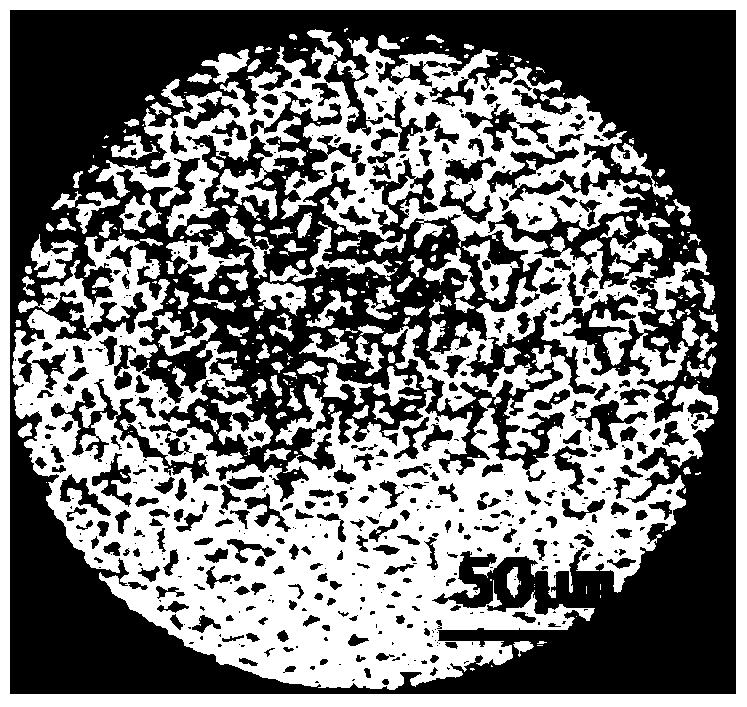

[0039] Embodiment three: Doping 200ppm, 800ppm Co and 2000ppm La in molybdenum powder 2 o 3 .

[0040] The difference between the third embodiment and the second embodiment is: doping 200ppm, 800ppm Co and 2000ppm La 2 o 3 , and the rest of the steps are the same to serve as a comparison example. La 2 o 3 The contents of Co and Co are shown in the test plans 11 and 12 of the attached table 1, and the evaluation effect of the molybdenum wire is shown in the comprehensive evaluation table of the doping test of the test plans 11 and 12 of the attached table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com