A kind of high performance neodymium iron boron material and preparation method thereof

A high-performance NdFeB technology, applied in the field of high-performance NdFeB materials and their preparation, can solve the problems of many restrictive factors, poor wear resistance of magnetic materials, large performance fluctuations of magnet materials, etc., and achieve good environmental adaptability , compact crystal, improved structural strength and magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

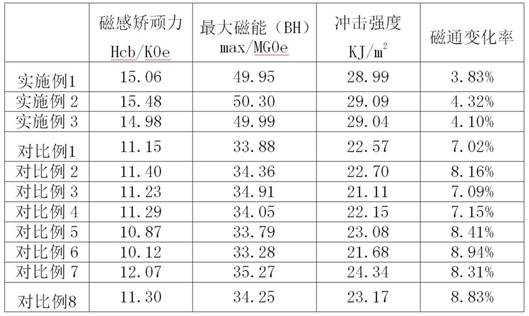

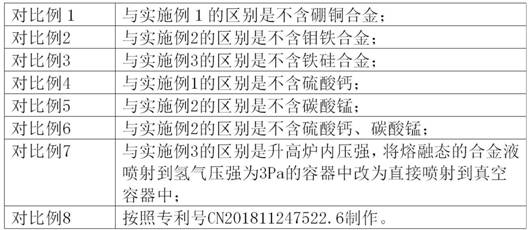

Embodiment 1

[0025] A high-performance NdFeB material, prepared from the following raw materials in parts by weight: 29 parts of magnesium-neodymium alloy, 1 part of zirconium-tin alloy, 1 part of iron-cobalt alloy, 1 part of boron-copper alloy, 0.5 part of cerium-iron alloy, and 0.5 part of zinc-iron alloy 5 parts, 1 part of molybdenum-iron alloy, 3 parts of iron-silicon alloy, 41 parts of iron powder, 0.1 part of calcium sulfate, 0.1 part of manganese carbonate, 0.3 part of microporous calcium silicate; The mass ratio of element and neodymium element is 5:3; the impurity content of the iron-cobalt alloy is lower than 0.3%, and the mass ratio of iron element and cobalt element is 8:1; the impurity content of the boron-copper alloy is lower than 0.1%, The mass ratio of copper element to boron element is 10:0.6; the mass ratio of iron element to cerium element in the cerium-iron alloy is 9:0.1; the impurity content of the zinc-iron alloy is lower than 0.3%, and the mass ratio of zinc element...

Embodiment 2

[0033]A high-performance NdFeB material, prepared from the following raw materials in parts by weight: 33 parts of magnesium-neodymium alloy, 2 parts of zirconium-tin alloy, 2 parts of iron-cobalt alloy, 2 parts of boron-copper alloy, 1 part of cerium-iron alloy, and zinc-iron alloy 8 parts, 3 parts of molybdenum-iron alloy, 5 parts of iron-silicon alloy, 43 parts of iron powder, 0.3 part of calcium sulfate, 0.3 part of manganese carbonate, 0.5 part of microporous calcium silicate; the impurity content of the magnesium neodymium alloy is less than 1%, magnesium The mass ratio of element and neodymium element is 7:4; the impurity content of the iron-cobalt alloy is lower than 0.3%, and the mass ratio of iron element and cobalt element is 10:1.3; the impurity content of the boron-copper alloy is lower than 0.1%, The mass ratio of copper element and boron element is 12:1.2; the mass ratio of iron element and cerium element in the cerium-iron alloy is 10:0.3; the impurity content o...

Embodiment 3

[0041] A high-performance NdFeB material, prepared from the following raw materials in parts by weight: 33 parts of magnesium-neodymium alloy, 1 part of zirconium-tin alloy, 2 parts of iron-cobalt alloy, 1 part of boron-copper alloy, 1 part of cerium-iron alloy, and zinc-iron alloy 5 parts, 3 parts of molybdenum-iron alloy, 3 parts of iron-silicon alloy, 43 parts of iron powder, 0.1 part of calcium sulfate, 0.3 part of manganese carbonate, 0.35 part of microporous calcium silicate; the impurity content of the magnesium neodymium alloy is less than 1%. The mass ratio of element and neodymium element is 7:3; the impurity content of the iron-cobalt alloy is lower than 0.3%, and the mass ratio of iron element and cobalt element is 10:1; the impurity content of the boron-copper alloy is lower than 0.1%, The mass ratio of copper element to boron element is 12:0.6; the mass ratio of iron element and cerium element in the cerium-iron alloy is 10:0.1; the impurity content of the zinc-ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com