A method for preparing low-content magnesium alloys with uniform and fine-grained variable temperature controlled rolling

A magnesium alloy, low-content technology, applied in the field of magnesium alloy materials, can solve the problems of reducing the grain refinement effect of magnesium alloy materials, recrystallized grain growth, dislocation recovery, etc. The effect of boundary energy and stabilizing grain boundary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

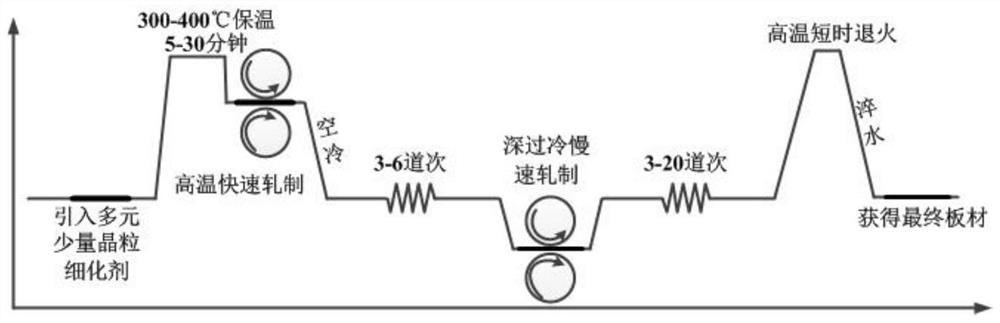

Method used

Image

Examples

Embodiment 1

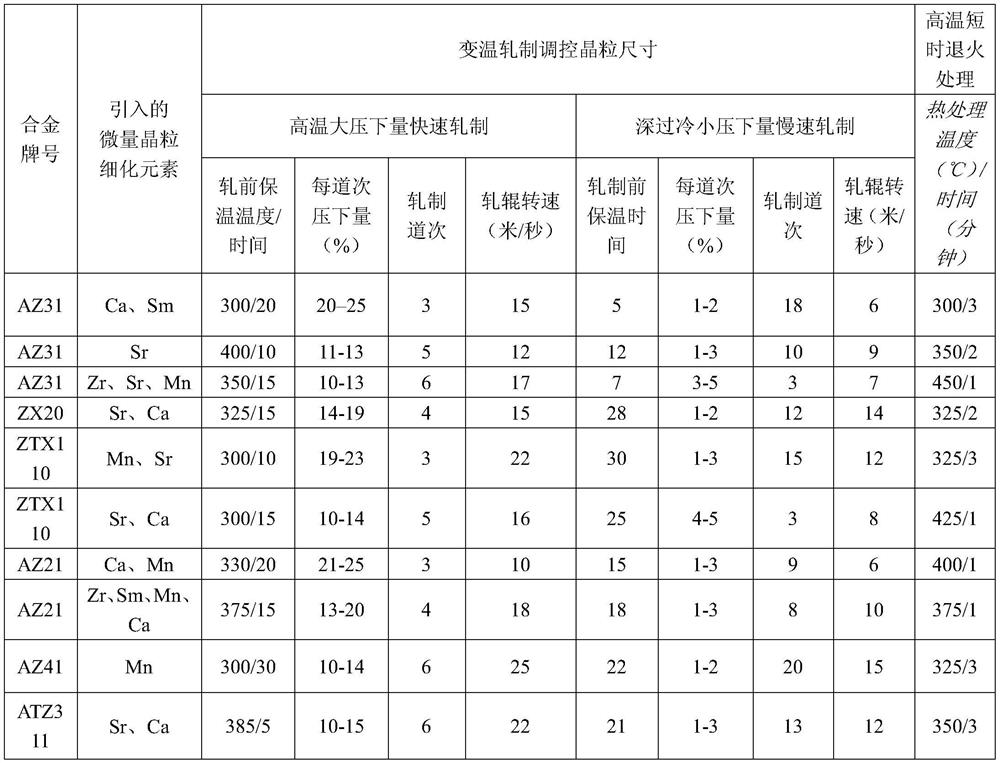

[0029] Embodiment 1: the concrete steps of this embodiment are as follows:

[0030] (1) The commercial AZ31 magnesium alloy is conventionally melted, and after refining, gas blowing and slag cleaning, it is kept at about 680°C to obtain a low-content commercial magnesium alloy melt;

[0031] (2) Add trace amounts of grain refining elements Ca and Sm to the above-mentioned low-content commercial magnesium alloy melt, the required total addition amount is ≤0.5wt%, blow argon and stir evenly, and keep warm for 10-20 minutes to make the melt low The content elements are fully reacted to obtain a low-content mixed magnesium alloy melt;

[0032] (3) pouring the above-mentioned low-content mixed magnesium alloy melt added with trace grain refining elements into a water-cooled copper mold to obtain a supersaturated solid-solution low-content magnesium alloy slab;

[0033] (4) High temperature and large reduction rapid rolling process: the above-mentioned supersaturated solid-solution...

Embodiment 2

[0036] Embodiment 2: the concrete steps of this embodiment are as follows:

[0037] (1) The commercial ZX20 magnesium alloy is conventionally melted, and after refining, gas blowing and slag removal, it is kept at about 680 ° C to obtain a low-content commercial magnesium alloy melt;

[0038](2) Add trace grain refinement elements Sr and Ca to the above-mentioned low-content commercial magnesium alloy melt, the required total addition amount is ≤0.5wt%, blow argon gas and stir evenly, and keep warm for 10-20 minutes to make the melt low The content elements are fully reacted to obtain a low-content mixed magnesium alloy melt;

[0039] (3) pouring the above-mentioned low-content mixed magnesium alloy melt added with trace grain refining elements into a water-cooled copper mold to obtain a supersaturated solid-solution low-content magnesium alloy slab;

[0040] (4) High temperature and large reduction rapid rolling process: the above-mentioned supersaturated solid-solution low-...

Embodiment 3

[0043] Embodiment 3: the concrete steps of this embodiment are as follows:

[0044] (1) The ZTX110 magnesium alloy is conventionally melted, and after refining, gas blowing and slag cleaning, it is kept at about 680 ° C to obtain a low-content commercial magnesium alloy melt;

[0045] (2) Add trace grain refinement elements Mn and Sr to the above-mentioned low-content magnesium alloy melt, the required total addition amount is ≤0.5wt%, blow argon and stir evenly, and keep warm for 10-20 minutes to make the low-content magnesium alloy in the melt The elements react fully to obtain a low-content mixed magnesium alloy melt;

[0046] (3) pouring the above-mentioned low-content mixed magnesium alloy melt added with trace grain refining elements into a water-cooled copper mold to obtain a supersaturated solid-solution low-content magnesium alloy slab;

[0047] (4) High-temperature and large-reduction rapid rolling process: the above-mentioned supersaturated solid-solution low-conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com