Microwave oven sintering method of producing silicon nitride ceramics heater and special equipment thereof

A technology of silicon nitride ceramics and special equipment is applied in the field of microwave oven sintering preparation to achieve the effects of reducing energy consumption, good product quality and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Microwave sintering of a silicon nitride ceramic heating element green body with dry-pressed buried wire.

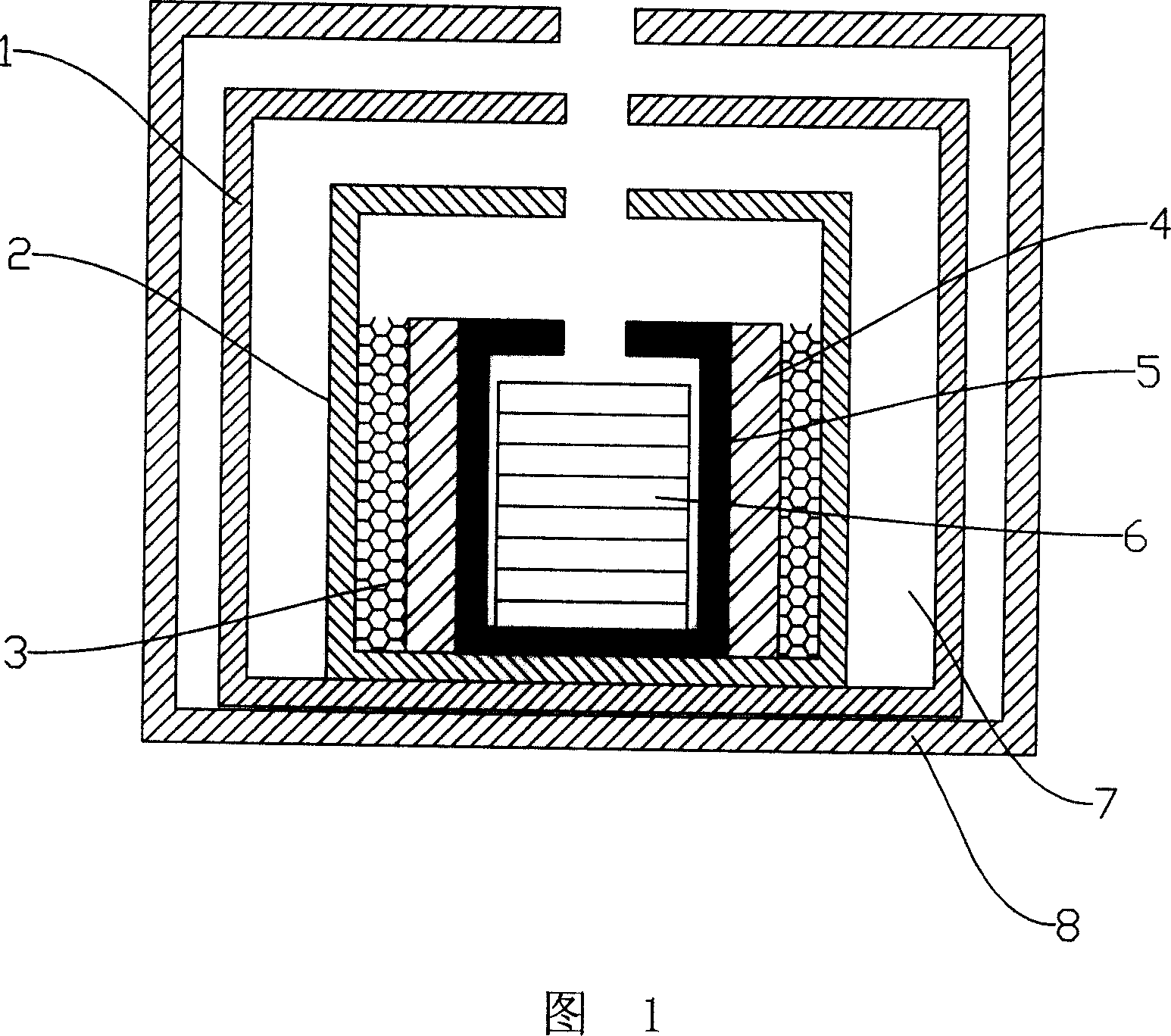

[0020] The special sintering equipment used in this embodiment is shown in FIG. 1 . The special equipment includes a microwave oven body 8 and a corundum crucible 5, in which a special insulation body for sintering is arranged, and the special insulation body for sintering includes: the outermost fiber insulation body 1, the second outer layer Layer insulation body 2, auxiliary heating plate 4 and fiber insulation ball filling layer 3; described corundum crucible is aluminum oxide Al 2 o 3 Made of materials, the auxiliary heating plate is made of silicon carbide SiC material, and the fiber insulation ball is made of alumina Al 2 o 3 Made of materials, the insulation body of the second outer layer is magnesium aluminum spinel-lanthanum chromate MgAl 2 o 4 -LaCrO 3 Material production; between the auxiliary heating plate 4 and the thermal insulation...

Embodiment 2

[0023] Example 2: Microwave sintering of silicon nitride ceramic heating element green body with dry-pressed buried wire.

[0024] First, the ceramic green body of the silicon nitride ceramic heating element made of dry-pressed buried wire made by raw material preparation, blank preparation and debinding process is put into alumina Al 2 o 3 In the corundum crucible 5, then the alumina Al 2 o 3 Corundum crucible with auxiliary heating plate made of silicon carbide SiC, alumina Al 2 o 3 Fiber insulation ball, magnesium aluminum spinel - lanthanum chromate MgAl 2 o 4 -LaCrO 3 Secondary insulation, aluminum oxide Al 2 o 3 The sintering special insulation body composed of fiber insulation body is put into the 2.45GHz multi-mode reaction chamber microwave sintering device as a whole. The microwave oven is first vacuumed to 10Pa, and then filled with 99.9% N 2 , repeat the above-mentioned vacuum pumping and N filling four times 2 program, to the microwave oven cavity N 2 T...

Embodiment 3

[0026] Example 3: Microwave sintering of silicon nitride ceramic heating element green body with film rolling and silk printing.

[0027] First, put the silicon nitride ceramic heating element green body of rolling film and silk screen printing made by raw material preparation, blank preparation and degumming process into alumina Al 2 o 3 A corundum crucible, then alumina Al 2 o 3 Corundum crucible with auxiliary heating plate made of silicon carbide SiC, alumina Al 2 o 3 Fiber insulation ball, magnesium aluminum spinel - lanthanum chromate MgAl 2 o 4 ~LaCrO 3次 Insulation body, aluminum oxide Al 2 o 3 The sintering special insulation body composed of fiber insulation body is put into the 2.45GHz multi-mode reaction chamber microwave sintering device as a whole. First, the microwave oven is evacuated to 10Pa, and then filled with N 2 , repeat the above-mentioned vacuuming and filling with N three times 2 program, to the microwave oven cavity N 2The content is higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com