Complex-shaped ceramic matrix composite part and preparation method thereof

A composite material and complex shape technology, which is applied in the field of complex shape ceramic matrix composite parts and its preparation, can solve the problems of limited application range, high brittleness and low toughness of silicon carbide ceramic materials, and achieve good packing density and excellent mechanical properties , the effect of high forming precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

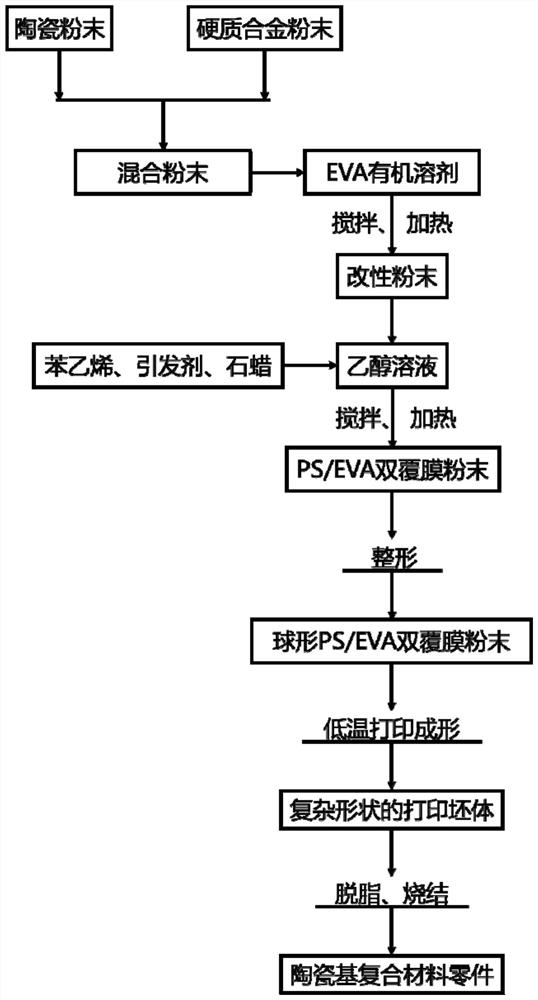

Method used

Image

Examples

Embodiment 1

[0044] Mix silicon carbide ceramic powder and WC-8wt.% Co cemented carbide powder uniformly at a mass ratio of 3.33:1 for later use, wherein the particle size of silicon carbide ceramic powder is 40-60 μm, WC-8wt.% Co cemented carbide The maximum particle size of the powder is 48 μm. Add the uniformly mixed powder into the toluene solution of ethylene-vinyl acetate copolymer, keep the reaction vessel airtight and set up a toluene collection device, wherein the mass ratio of the mixed powder to EVA is 31:0.72; stir the mixed solution and raise the temperature to 50°C for 2 hours After the reaction is complete, the modified powder is obtained by suction filtration, drying, grinding and sieving. Disperse the modified powder evenly in the ethanol solution, the amount of ethanol should be such that the stirring paddle of the reactor is below the liquid level, add styrene, dibenzoyl peroxide, and paraffin, and the mass ratio of the mixed powder to styrene is 18:0.89, the mass ratio...

Embodiment 2

[0046] The silicon carbide ceramic powder and TiC-2wt.%Ni-2wt.%Mo cemented carbide powder are uniformly mixed at a mass ratio of 4:1 for later use, wherein the particle size of the silicon carbide ceramic powder is 35-50μm, and the TiC-2wt. The maximum particle size of %Ni-2wt.%Mo cemented carbide powder is 36μm. Add the uniformly mixed powder into the toluene solution of ethylene-vinyl acetate copolymer, keep the reaction vessel airtight and set up a toluene collection device, wherein the mass ratio of the mixed powder to EVA is 31:0.65; stir the mixed solution and raise the temperature to 50°C for 4 hours After the reaction is complete, the modified powder is obtained by suction filtration, drying, grinding and sieving. Disperse the modified powder evenly in the ethanol solution, the amount of ethanol should be such that the stirring paddle of the reactor is below the liquid level, add styrene, dibenzoyl peroxide, and paraffin, and the mass ratio of the mixed powder to styre...

Embodiment 3

[0048] The silicon carbide ceramic powder and TiC-2wt.%Ni-2wt.%Mo cemented carbide powder are uniformly mixed at a mass ratio of 6:1, and the particle size of the silicon carbide ceramic powder is 35-60μm, and the TiC-2wt. The maximum particle size of %Ni-2wt.%Mo cemented carbide powder is 40μm. Add the uniformly mixed powder into the toluene solution of ethylene-vinyl acetate copolymer, keep the reaction vessel airtight and set up a toluene collection device, wherein the mass ratio of mixed powder to EVA is 31:0.60; stir the mixed solution and heat up to 55°C for 3h After the reaction is complete, the modified powder is obtained by suction filtration, drying, grinding and sieving. Disperse the modified powder evenly in the ethanol solution, the amount of ethanol added should make the stirring paddle of the reactor below the liquid level, add styrene, dibenzoyl peroxide, paraffin, the mass ratio of modified powder to styrene It is 18:0.83, and the mass ratio to paraffin is 37...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com