Wear-resistant aluminum alloy and preparation method thereof

An aluminum alloy and alloying technology, which is applied in the field of new high wear-resistant aluminum alloy and its preparation, can solve the problems of poor wear resistance and low hardness of aluminum alloy, achieve fine dispersion strengthening phase, increase tensile strength, and crystal The effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

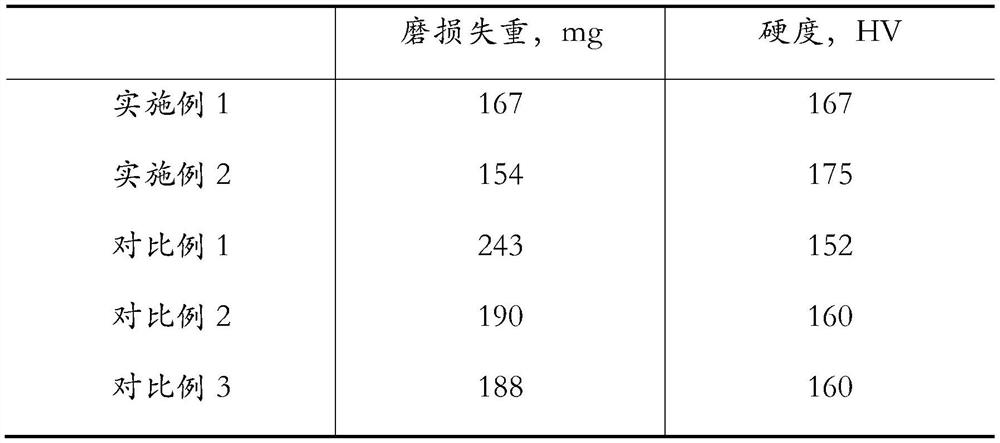

Examples

Embodiment 1

[0034] The composition of the wear-resistant aluminum alloy in this embodiment is: 10.4% Si, 1.5% Zr, 1.2% Ti, 0.05% Cu, 1.2% Sn, 0.5% Mn, 1.4% Nb, 0.07% Fe, 0.03% Ni, 0.05% Cr, 0.14% V, 0.2% Mo, and the balance is Al.

[0035] The preparation method of the wear-resistant aluminum alloy of the present invention adopts the following steps:

[0036] Step (1), prepare aluminum alloy powder:

[0037] The powders of Si, Zr, Ti, Cu, Sn, Mn, Nb, Fe, Ni, Cr, V, and Mo are prepared according to the mass percentage composition of claim 1, and the particle size of all these powders is 100-200 mesh, The purity is 99.9% grade.

[0038] Step (2), high-energy ball milling alloying:

[0039] The metal powder prepared according to step (1) is put into a zirconia ball mill jar, then the ball mill jar is evacuated, and a planetary ball mill is used for ball milling. Small ball: 5mm, the ratio of ball mill balls is 1:2:4 by mass, the ratio of ball to material is 5:1, the ball milling medium is ...

Embodiment 2

[0052] The composition of the wear-resistant aluminum alloy of this embodiment is: 10.9% Si, 2% Zr, 1.7% Ti, 0.07% Cu, 1.5% Sn, 0.6% Mn, 1..7% Nb, 0.15% Fe, 0.12% Ni, 0.1% Cr, 0.19% V, 0.21% Mo, and the balance is Al.

[0053] The preparation method of the wear-resistant aluminum alloy of the present invention adopts the following steps:

[0054] Step (1), prepare aluminum alloy powder:

[0055] The powders of Si, Zr, Ti, Cu, Sn, Mn, Nb, Fe, Ni, Cr, V, and Mo are prepared according to the mass percentage composition of claim 1, and the particle size of all these powders is 100-200 mesh, The purity is 99.9% grade.

[0056] Step (2), high-energy ball milling alloying:

[0057] The metal powder prepared according to step (1) is put into a zirconia ball mill jar, then the ball mill jar is evacuated, and a planetary ball mill is used for ball milling. Small ball: 5mm, the ratio of ball mill balls is 1:2:4 by mass, the ratio of ball to material is 5:1, the ball milling medium is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com