Preparation method of nano zirconium oxide and chromium oxide composite material

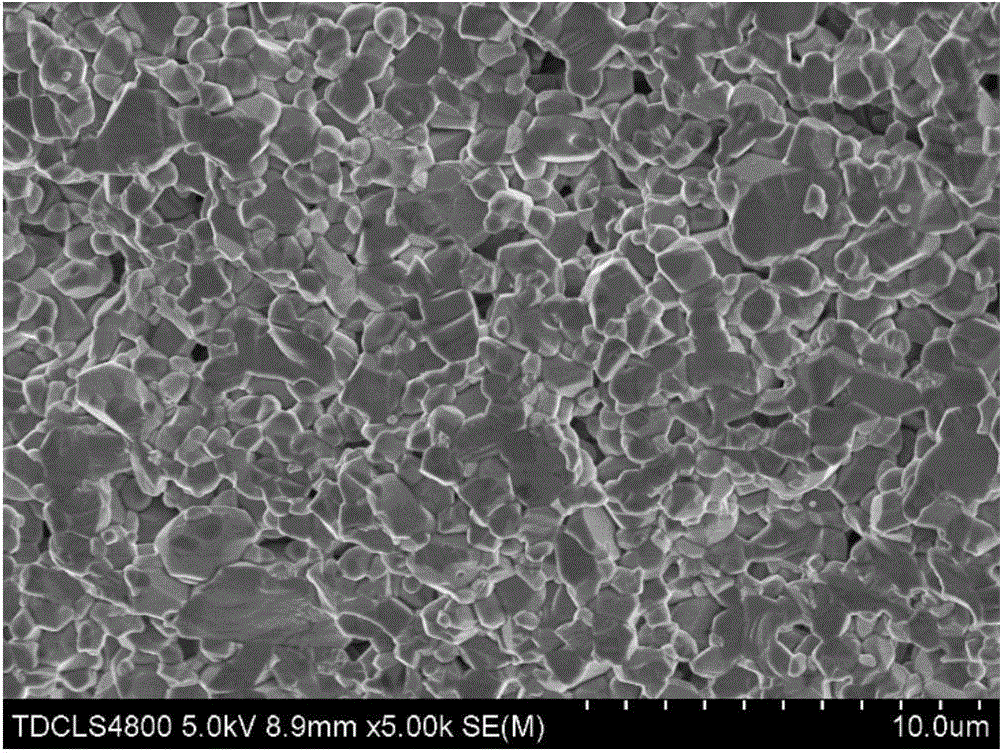

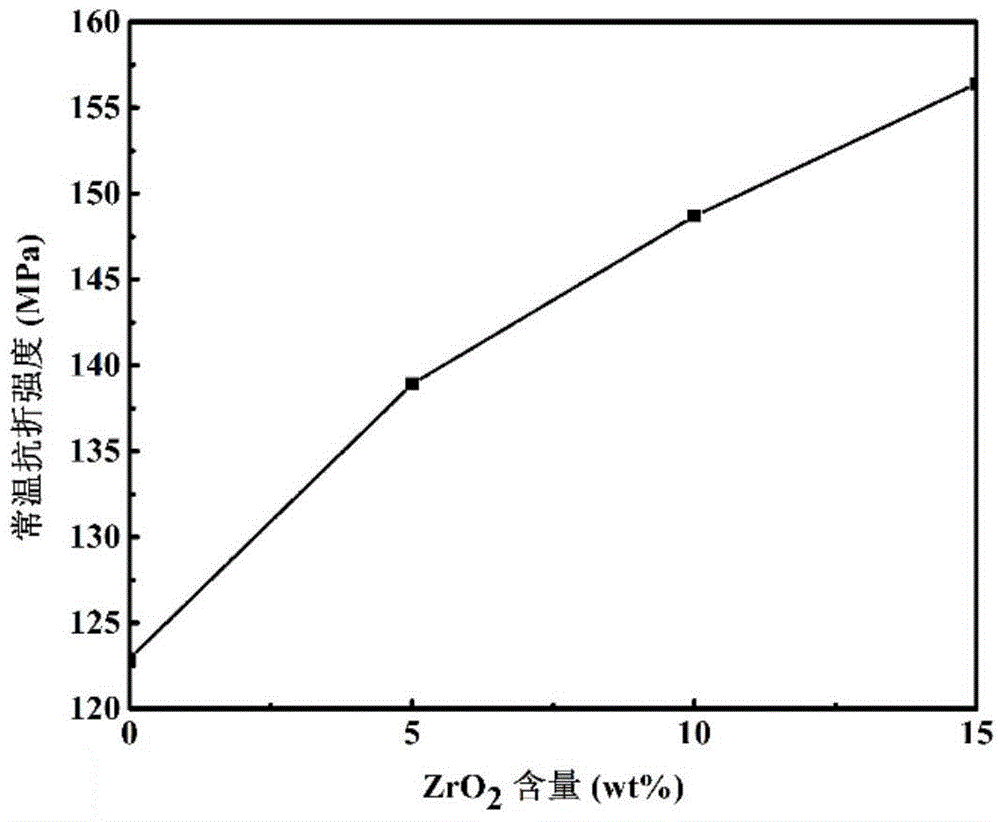

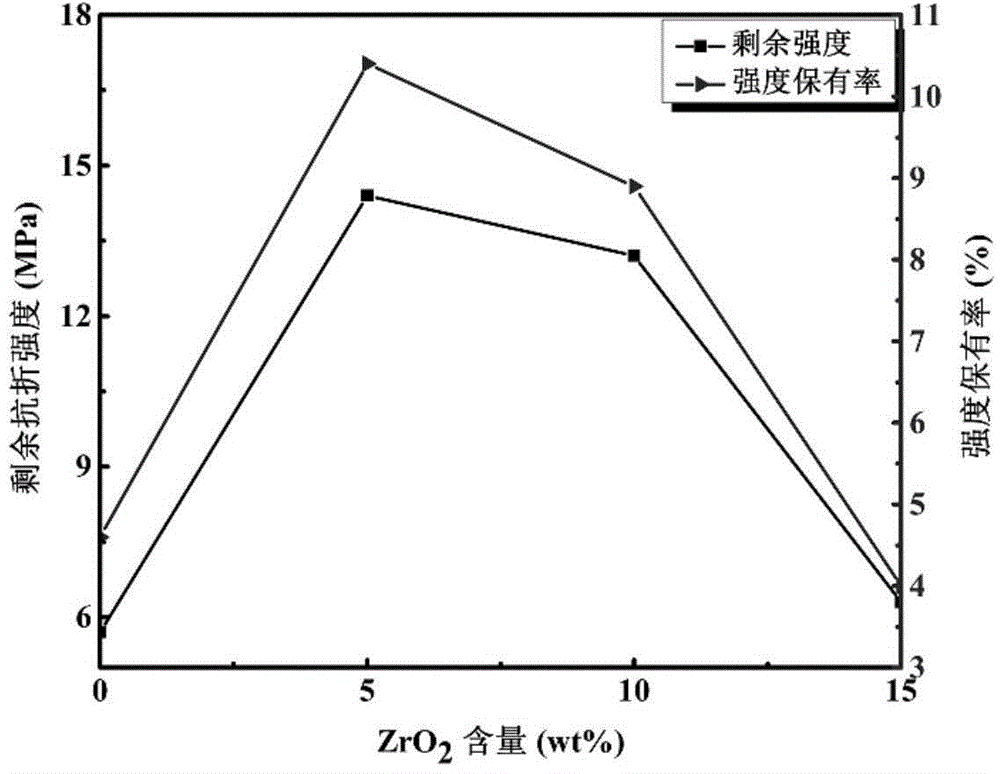

A nano-zirconia and composite material technology, applied in the field of refractory performance improvement, can solve the problems of harsh working environment, material peeling and cracking, material strength decline, etc., and achieve excellent mechanical properties, uniform microstructure and good fine grain structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: prepare nano zirconia and chromium oxide composite material, concrete steps are as follows:

[0025] Step 1, preparation of dispersion: 0.9wt% maleic acid-acrylic acid copolymer accounting for chromium oxide micropowder, nano zirconia powder and titania micropowder total mass Add 0.08wt% sodium tripolyphosphate as a composite dispersant to deionized water, adjust the pH to 9 with ammonia water, and obtain a dispersion;

[0026] Step 2, prepare slurry: mix 87wt% chromium oxide micropowder, 10wt% nano zirconia powder, 3wt% titanium dioxide micropowder with the dispersion liquid prepared in step 1, and obtain a stable dispersed slurry after ball milling for 6 hours;

[0027] Step 3, drying of the slurry: drying the slurry obtained in step 2 at 120°C to obtain the mixed powder;

[0028] Step 4, forming: adding a PVA aqueous solution with a concentration of 5wt% to the mixed powder obtained in step 3, and making a molded green body under a pressure of 90 MPa; ...

Embodiment 2

[0032] Embodiment 2: Preparation of nano zirconia and chromium oxide composite material.

[0033] The preparation process of embodiment 2 is basically the same as that of embodiment 1, the only difference is that in step 2, 82wt% chromium oxide micropowder, 15wt% nano zirconia, 3wt% titanium dioxide micropowder are mixed with the dispersion prepared in step 1, ball milled After 6 hours, a stable and dispersed slurry was obtained; the molding pressure in step 4 was 110 MPa; the sintering temperature in step 6 was 1550° C., and the holding time was 2.5 hours.

[0034] The bulk density of the composite material of nano zirconia and chromium oxide prepared in embodiment 2 is 5.02g / cm 3 , the porosity is 3.1%, and the three-point bending strength is 260.2MPa.

Embodiment 3

[0035] Embodiment 3: Preparation of nano zirconia and chromium oxide composite material.

[0036] The preparation process of Example 3 is basically the same as that of Example 2, except that the molding pressure in Step 4 is 100 MPa; the sintering temperature in Step 6 is 1350° C., and the holding time is 2.5 hours.

[0037] The bulk density of the composite material of nano-zirconia and chromium oxide prepared in embodiment 3 is 4.39g / cm 3 , the porosity is 16.7%, and the three-point bending strength is 112.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com