Method for preparing graphene reinforced aluminum matrix composite material by microwave sintering

A microwave sintering and composite material technology, which is applied in the field of metal matrix composite material preparation, can solve the problems of hindering heat flow, poor interface bonding, and large interface thermal resistance, achieving good compactness, shortening preparation time, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

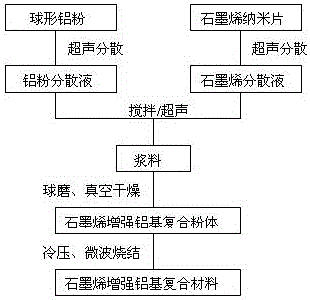

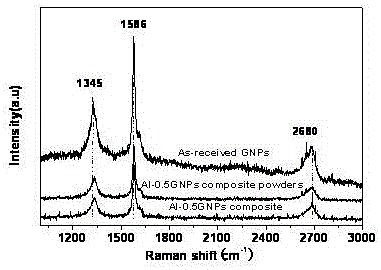

[0020] Step 1: Add 0.05 grams of graphene nano-chips into 50 ml of absolute ethanol, and ultrasonically vibrate for 30 minutes to obtain a graphene dispersion;

[0021] Step 2: Add 10 grams of aluminum powder to 50 ml of absolute ethanol, and oscillate ultrasonically for 25 minutes to obtain an aluminum powder dispersion;

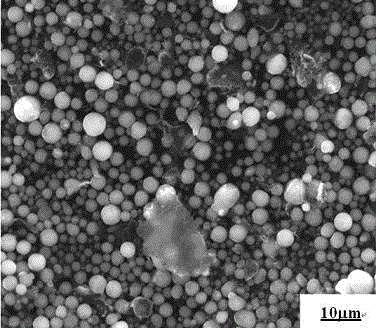

[0022] Step 3: Mix the above-mentioned aluminum powder dispersion and graphene dispersion, and ultrasonically mix for 1.5 hours to obtain a mixed slurry; place the mixed slurry in a ball mill tank, vacuumize the ball mill tank, fill it with argon protection, seal it, and place it On the machine base, the cold air generated by the liquid nitrogen refrigeration system is continuously input into the planetary ball mill equipped with a heat preservation cover. The cold air absorbs and takes away the heat generated by the high-speed rotating ball mill tank in time, so that the ball mill tank is always in a certain low temperature environment. Among them, low-tem...

Embodiment 2

[0026] Step 1: Add 0.2 grams of graphene nano-chips into 50 ml of absolute ethanol, and ultrasonically vibrate for 100 minutes to obtain a graphene dispersion;

[0027] Step 2: Add 10 grams of aluminum powder to 50 ml of absolute ethanol, and ultrasonically oscillate for 50 minutes to obtain an aluminum powder dispersion; mix the above aluminum powder dispersion with graphene dispersion, and ultrasonically mix for 2.5 hours to obtain a mixed slurry; mix the mixed slurry The body is placed in the ball mill jar, after vacuuming the ball mill jar, it is filled with argon gas for protection and then sealed, and placed on the machine base, the cold air generated by the liquid nitrogen refrigeration system is continuously input into the planetary ball mill equipped with a heat preservation cover, and these cold air will be transferred at a high speed The heat generated by the rotating ball milling tank is absorbed and taken away in time, so that the ball milling tank is always in a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com