High voltage lithium ion battery cathode material and preparation method thereof

A cathode material, lithium ion technology, applied in the field of cathode material of lithium ion battery and its preparation, can solve the problems of high energy consumption and long heating time, and achieve the effects of low consumption, short sintering time and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

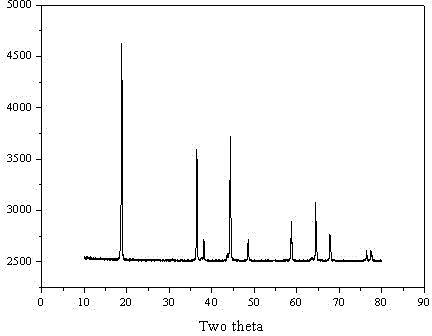

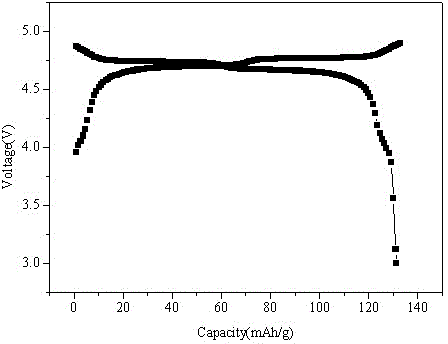

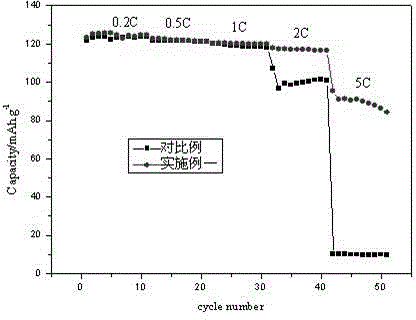

Image

Examples

Embodiment 1

[0031] A lithium ion battery positive electrode material is prepared by the following method:

[0032] 1) According to the chemical formula LiNi 0.5 mn 1.475 Cr 0.025 o 3.975 f 0.025 The stoichiometry of Ni(NO 3 ) 2 ·6H 2 O, Cr(NO 3 ) 3 9H 2 O and 50%Mn(NO 3 ) 2 Formulated with a total metal ion concentration of 2mol L -1The mixed solution; Weigh Na 2 CO 3 The same concentration is 2mol L -1 solution; the two solutions are dropped into a reaction tank filled with about 400mL of distilled water at the same time, stir the co-precipitation solution and add NaOH to control the pH value between 7-8. At 55°C, control the rate of addition so that the two solutions are added dropwise in about 2 hours. After the reaction was completed, stirring was continued for 2 h. Wash the precipitate several times, filter it with suction and dry it in a drying oven at 120°C.

[0033] 2) Grind the dried product, put it in a muffle furnace for calcination under air atmosphere, and p...

Embodiment 2

[0036] A lithium ion battery positive electrode material is prepared by the following method:

[0037] 1) According to the chemical formula LiNi 0.475 mn 1.475 co 0.5 o 3.95 f 0.05 The stoichiometry of Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and 50%Mn(NO 3 ) 2 Formulated with a total metal ion concentration of 2mol L -1 The mixed solution; Weigh Na 2 CO 3 The same concentration is 2mol L -1 solution; the two solutions are dropped into a reaction tank filled with about 400mL of distilled water at the same time, stir the co-precipitation solution and add NaOH to control the pH value between 7-8. At 30°C, control the rate of addition so that the two solutions are added dropwise in about 4 hours. After the reaction was completed, stirring was continued for 2 h. Wash the precipitate several times, filter it with suction and dry it in a drying oven at 120°C.

[0038] 2) Grind the dried product, put it in a muffle furnace for calcination under air atmosphere, and p...

Embodiment 3

[0041] A lithium ion battery positive electrode material is prepared by the following method:

[0042] 1) According to the chemical formula LiNi 0.5 mn 1.45 Mg 0.025 Cr 0.025 o 3.95 f 0.05 The stoichiometry of Ni(NO 3 ) 2 ·6H 2 O, Mg(NO 3 ) 2 ·6H 2 O, Cr(NO 3 ) 3 9H 2 O and 50%Mn(NO 3 ) 2 Formulated with a total metal ion concentration of 2mol L -1 The mixed solution; Weigh Na 2 CO 3 The same concentration is 2mol L -1 solution; the two solutions are dropped into a reaction tank filled with about 400mL of distilled water at the same time, stir the co-precipitation solution and add NaOH to control the pH value between 7-8. At 45°C, control the rate of addition so that the two solutions are added dropwise in about 3 hours. After the reaction was completed, stirring was continued for 2 h. Wash the precipitate several times, filter it with suction and dry it in a drying oven at 120°C.

[0043] 2) Grind the dried product, put it in a muffle furnace for calcina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com