Fuel cell catalyst and preparation method thereof

A fuel cell and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of insignificant effect of anti-poisoning ability, easy poisoning, and reduced catalyst activity, etc. Poisoning ability, not easy to peel off, good conductivity and effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of fuel catalyst, comprising:

[0040] a) mixing the carbon carrier with an acid salt solution containing rare earth elements to obtain a suspension;

[0041] b) precipitating the rare earth elements in the suspension with an alkaline substance to obtain a carbon carrier composited with hydroxides of the rare earth elements;

[0042] c) sintering the carbon carrier composited with the hydroxide of the rare earth element to obtain a composite carrier;

[0043] d) mixing the precursor of the noble metal with the composite carrier, and microwave sintering to obtain the fuel cell catalyst.

[0044] According to the present invention, at first prepare the acidic salt solution containing rare earth element,

[0045] a1) dissolving rare earth oxides in concentrated nitric acid to obtain an acid salt solution containing rare earth elements;

[0046] a2) carrying out the acid salt solution with 1:1 ethanol and secondary...

Embodiment 1

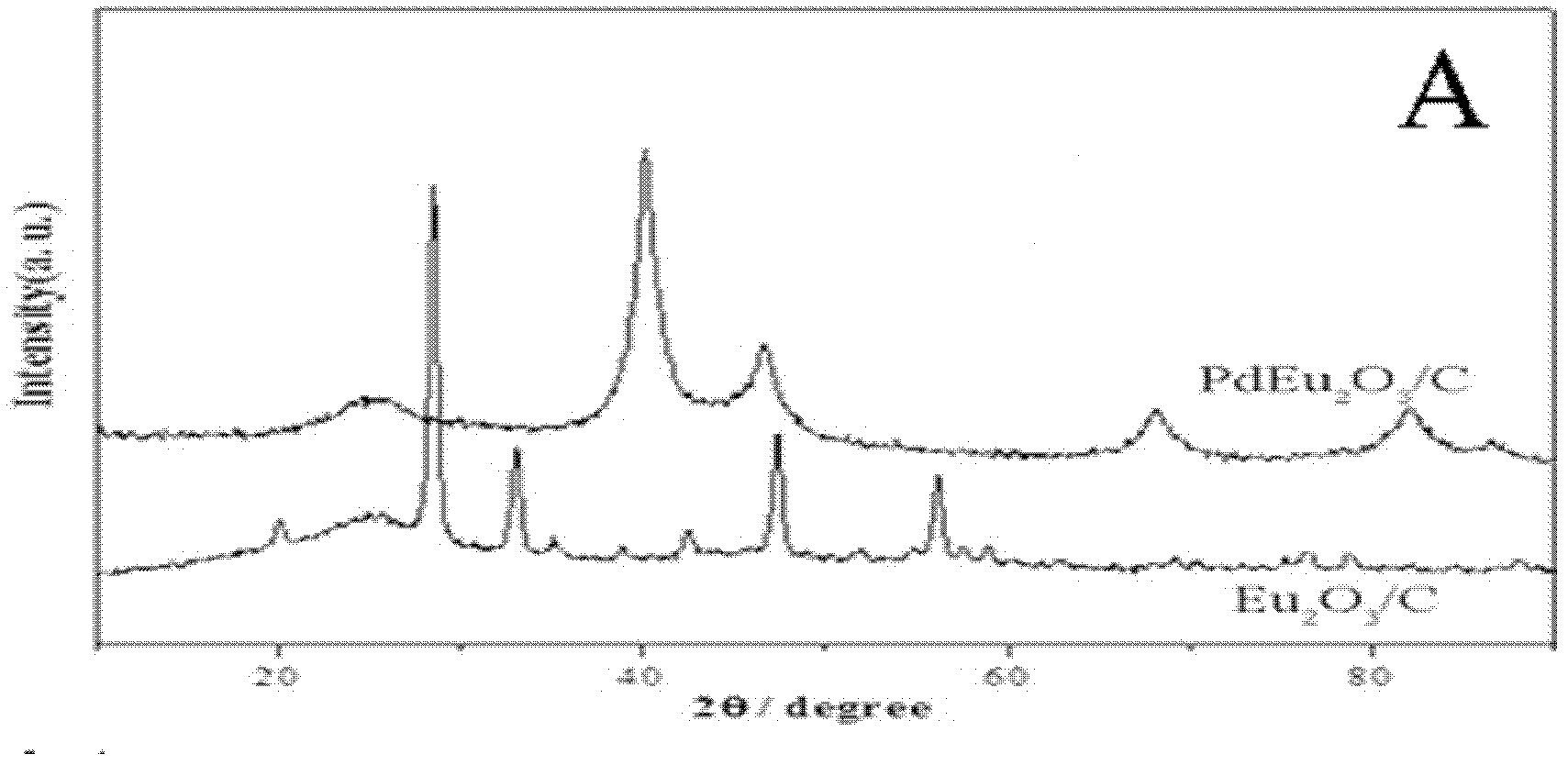

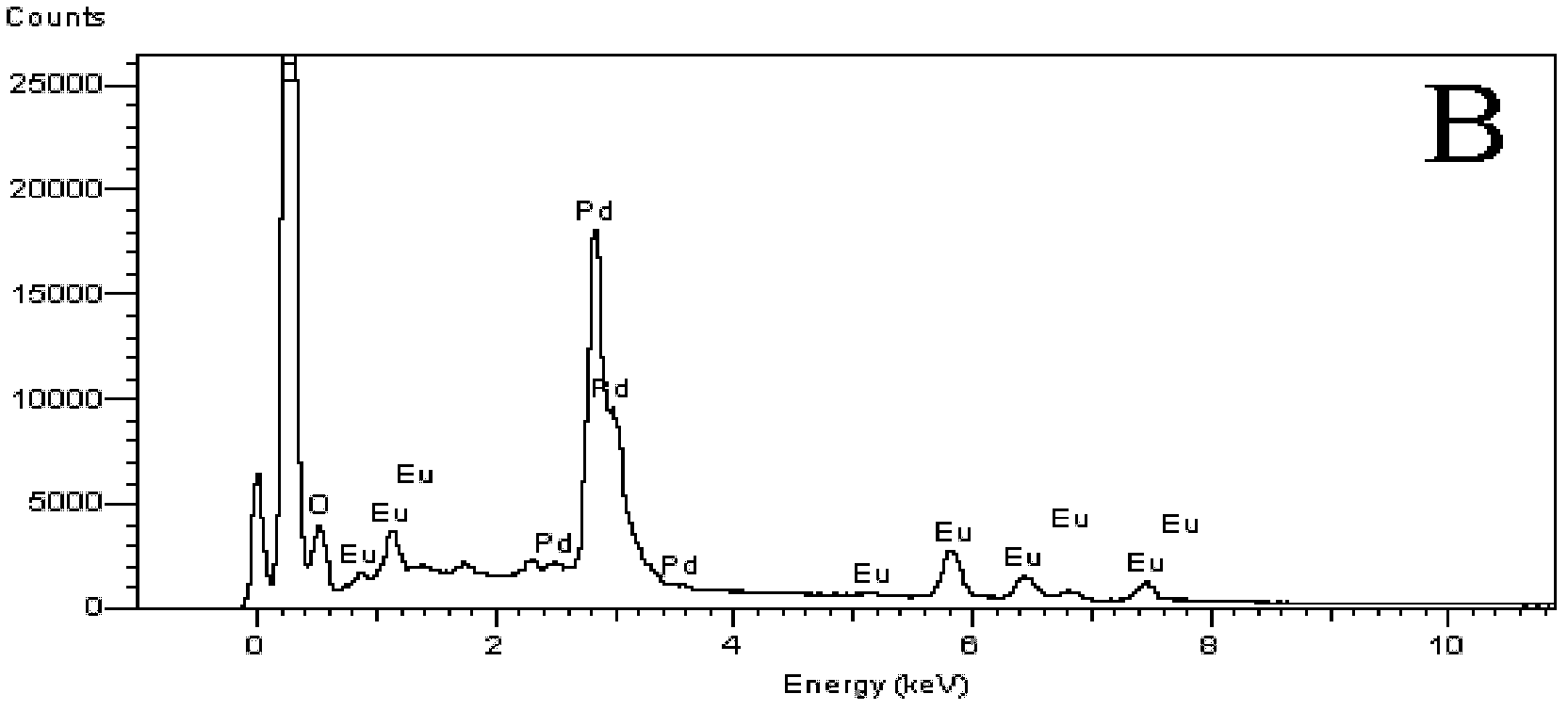

[0063] ReO to Eu 2 o 3 Taking rare earth oxides as an example, Pd is used as a noble metal, and the mass content of Pd and rare earth oxides in PdEuO / C is 20% and 15% for illustration.

[0064] Weigh 20mg of rare earth oxide (Eu 2 o 3 ) was dissolved in 10ml of concentrated nitric acid, and then diluted with 40ml of 1:1 ethanol and secondary water. Add 80mg of activated carbon to the above solution for half an hour of ultrasonic treatment and 2 hours of mechanical stirring, then add 100ml of 1M sodium carbonate solution and 10mL of 1M sodium hydroxide to the above solution to form Eu 2 o 3 precipitation. Finally, the above mixed solution is filtered, washed, and the solid matter is transferred to a tube furnace for thermal decomposition treatment at a certain temperature under the protection of nitrogen to obtain stable Eu 2 o 3 / C composite carrier. 80 mg of the composite carrier obtained above and a certain amount of noble metal precursor H 2 PdCl 6 (containing 20m...

Embodiment 2

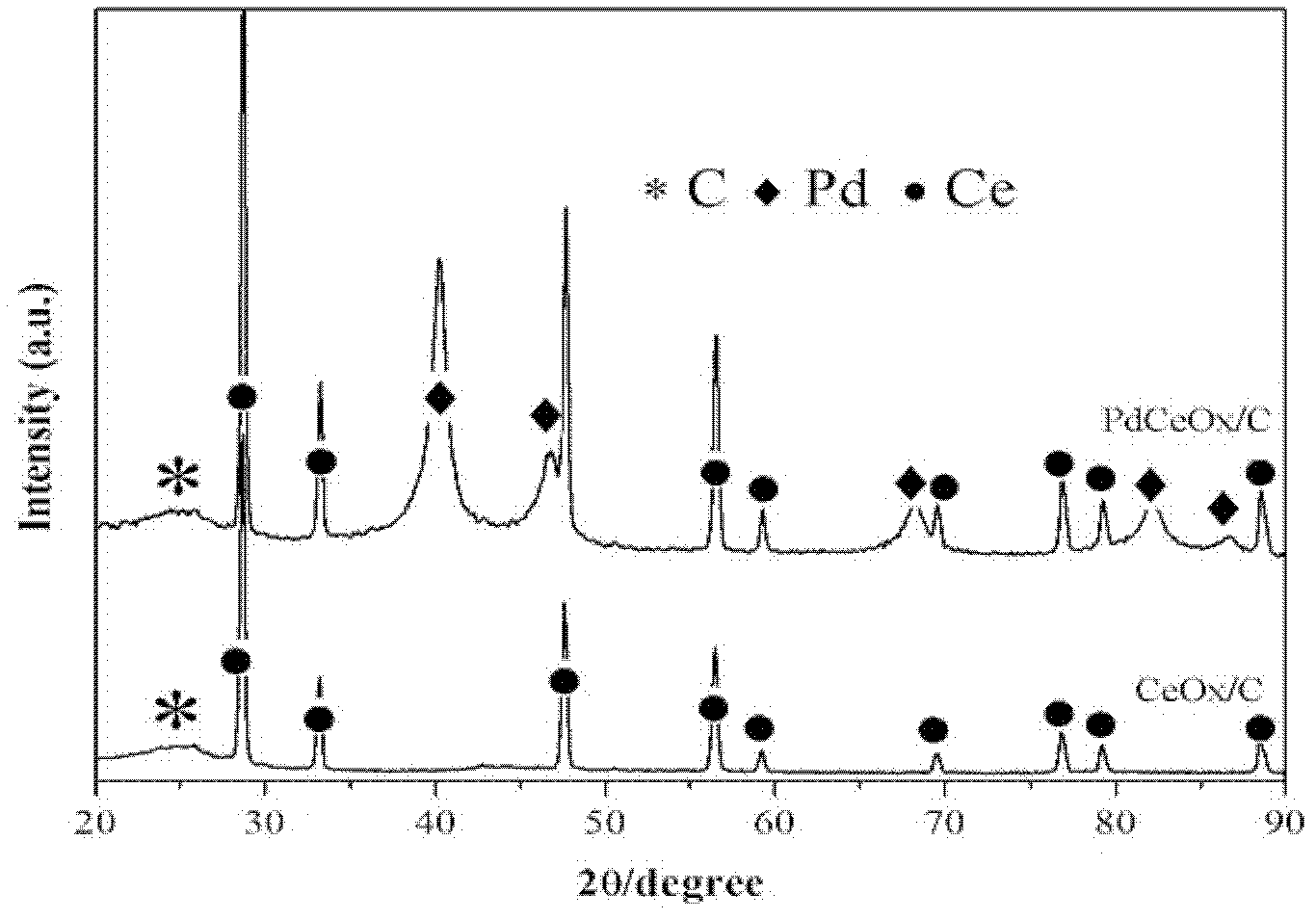

[0066] ReO to Ce 2 o 3 Rare earth oxides are taken as an example, and Pd is used as a noble metal, and its content and preparation method are the same as above.

[0067] image 3 is Pd Ce 2 o 3 / C and Ce 2 o 3 The XRD pattern of the C carrier, it can be seen from the figure that Ce 2 o 3 and Pd diffraction peaks exist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com