Aluminium-based composite material with high silicon carbide content and preparation method of composite material

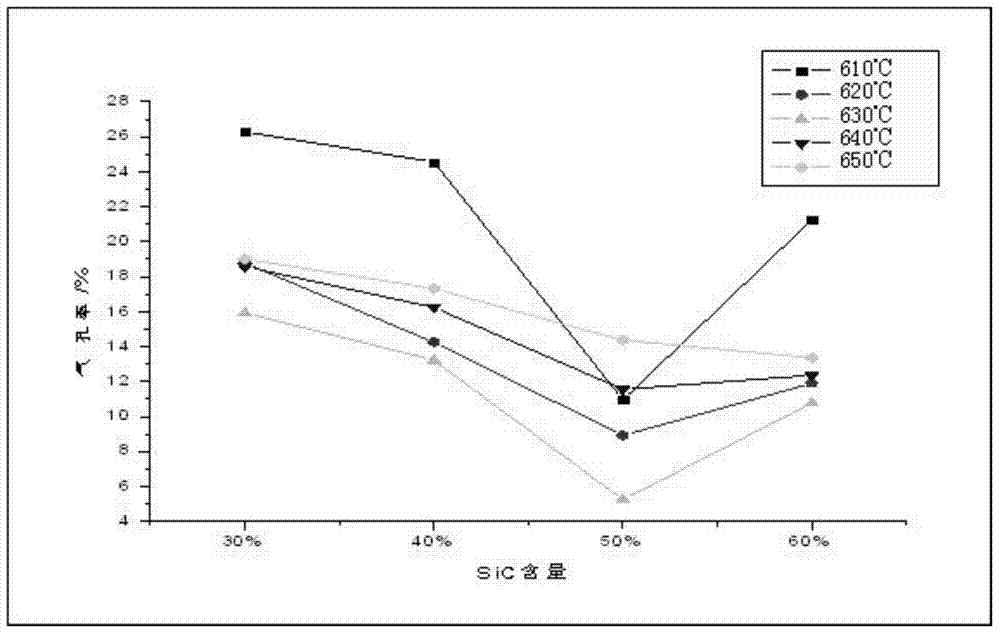

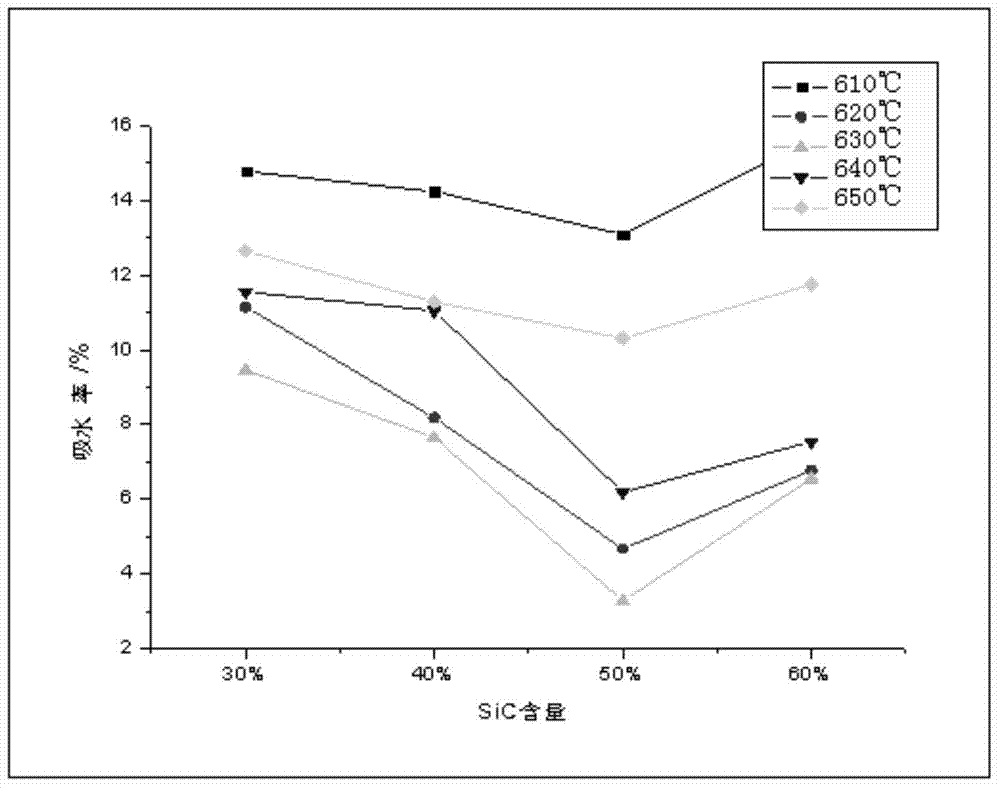

An aluminum-based composite material, high silicon carbide technology, applied in the field of silicon carbide particle reinforced aluminum-based composite material, can solve the problems of component segregation, affecting the comprehensiveness of composite materials, poor wettability between silicon carbide particles and aluminum alloy solution, etc. High relative density, solving composition segregation and stomatal inclusions, and good organizational uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The silicon carbide aluminum-based composite material is prepared and proportioned according to the following mass percentages: 40% silicon carbide and 60% aluminum, wherein the particle size of silicon carbide is 10-15um, and the particle size of aluminum powder is 6-10um.

[0028] (2) Put the above raw materials into the stainless steel mixing tank, and put them in according to the ball-to-material ratio of 0.4:1 After sealing the WC ball, turn on the mixer and mix for 8 hours. After mixing, add stearic acid alcohol solution to the mixed powder and continue mixing for 2 hours. Dry it in vacuum at 60°C. The amount of stearic acid added is the same as that of silicon carbide and aluminum 3% of the sum of mass.

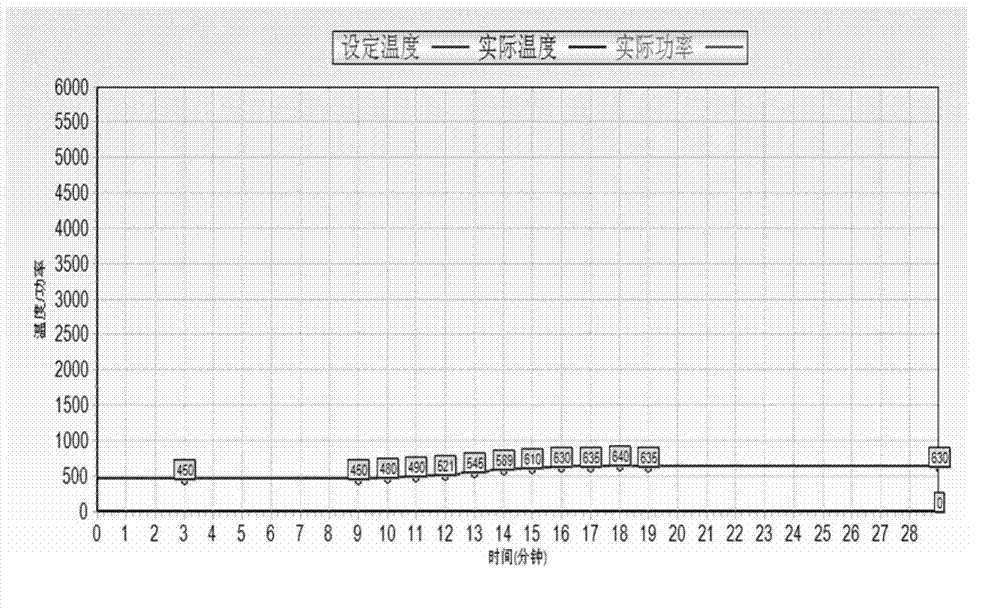

[0029] (3) Use an automatic forming press to compress the dried composite powder. The pressing pressure is 250MPa, the pressing speed is 5.2mm / min in both directions, and the pressure is maintained for 50s. The upper punch is started. After the upper punch ...

Embodiment 2

[0034] (1) The silicon carbide aluminum-based composite material is prepared and formulated according to the following mass percentages: silicon carbide 60%, aluminum 40%, wherein the particle size of silicon carbide is 10-15um, and the particle size of aluminum powder is 6-10um.

[0035] (2) Put the above raw materials into the stainless steel mixing tank, and put them in according to the ball-to-material ratio of 0.42:1 After sealing the WC ball, turn on the mixer and mix for 7 hours. After mixing, add stearic acid alcohol solution to the mixed powder and continue mixing for 2.5 hours. Dry it in vacuum at 60°C. The amount of stearic acid added is the same as that of silicon carbide and aluminum 3% of the sum of mass.

[0036](3) Use an automatic forming press to suppress the dried composite powder. The pressing pressure is 270MPa, the pressing speed is 6mm / min in both directions, and the pressure is maintained for 60s. The upper punch is started. After the upper punch is in...

Embodiment 3

[0041] (1) The silicon carbide aluminum-based composite material is prepared and prepared according to the following mass percentages: 50% silicon carbide and 50% aluminum, wherein the particle size of silicon carbide is 10-15um, and the particle size of aluminum powder is 6-10um.

[0042] (2) Put the above raw materials into the stainless steel mixing tank, and put them in according to the ball-to-material ratio of 0.45:1 After sealing the WC ball, turn on the mixer and mix for 8 hours. After mixing, add stearic acid alcohol solution to the mixed powder and continue mixing for 2 hours. Dry it in vacuum at 60°C. The amount of stearic acid added is the same as that of silicon carbide and aluminum 3% of the sum of mass.

[0043] (3) Use an automatic forming press to compress the dried composite powder. The pressing pressure is 260MPa, the pressing speed is 5.5mm / min in both directions, and the pressure is maintained for 55s. The upper punch is started. After the upper punch is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com