Metal ceramic cutting tool material and preparation method thereof

A cutting tool and cermet technology, applied in the field of cermet cutting tool materials and their preparation, can solve the problems of difficult process control, poor sintered body uniformity, difficult high-performance sintered body, etc., to achieve easy control of the preparation process, increase pressure The effect of solid density and stable yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the examples, and the present invention is not limited within the scope of the examples.

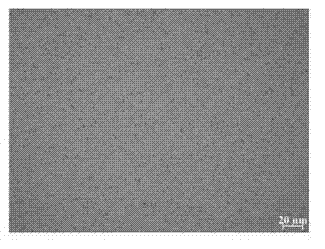

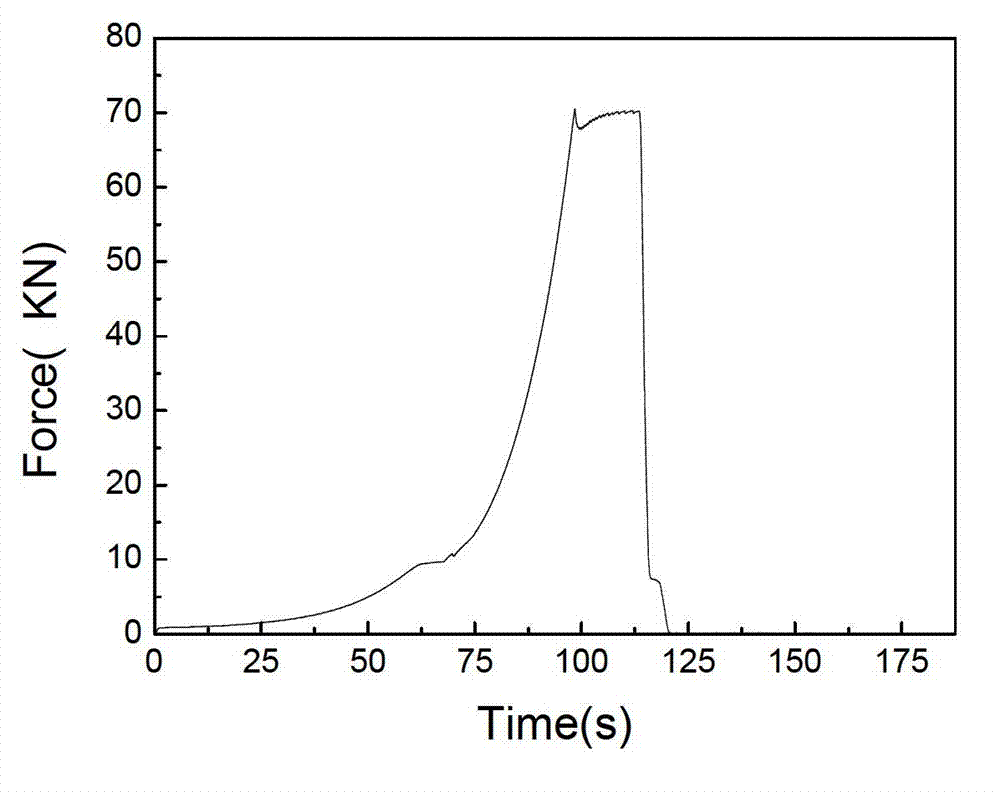

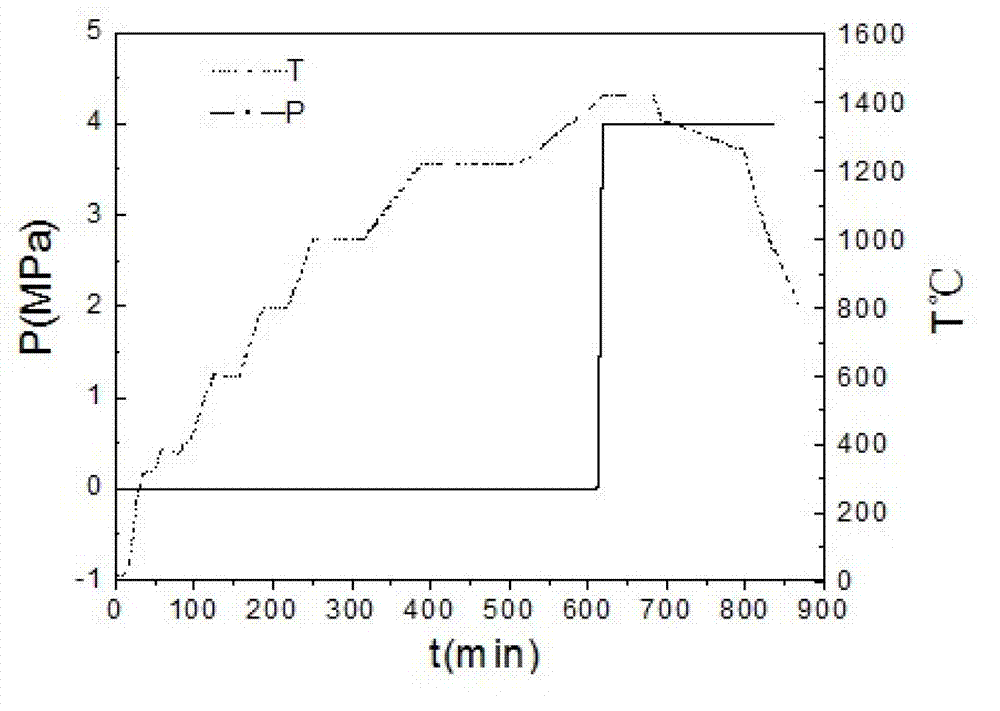

[0027] The batching scheme of Examples 1 to 9 is carried out by using the original powder composition scheme (Table 1) and the particle size optimization combination scheme of each component (Table 2) in the present invention. After the batching is completed, the conventional wet mixing process is used to fully mix in the mixing tank, and it can be made into powder after drying. Pressing and forming under a certain pressure (160Mpa), the pressing curve is as follows figure 1 shown. The green compact is placed in a vacuum furnace for early high-vacuum sintering, and the vacuum degree is kept at 10~10°C below 400°C. -2 Between Pa, the temperature is 400°C~1400°C, and the vacuum degree is kept at 10 -2 10 -3 Pa, then rush into argon for low-pressure sintering, the sintering temperature is listed in Table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com