Tungsten alloy high temperature tool materials

a tool material and high-temperature technology, applied in the direction of coatings, layered products, chemistry apparatuses and processes, etc., can solve the problems of insufficient high-temperature hardness of metallic tool materials, insufficient wear resistance and toughness, and a tendency to deform under stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

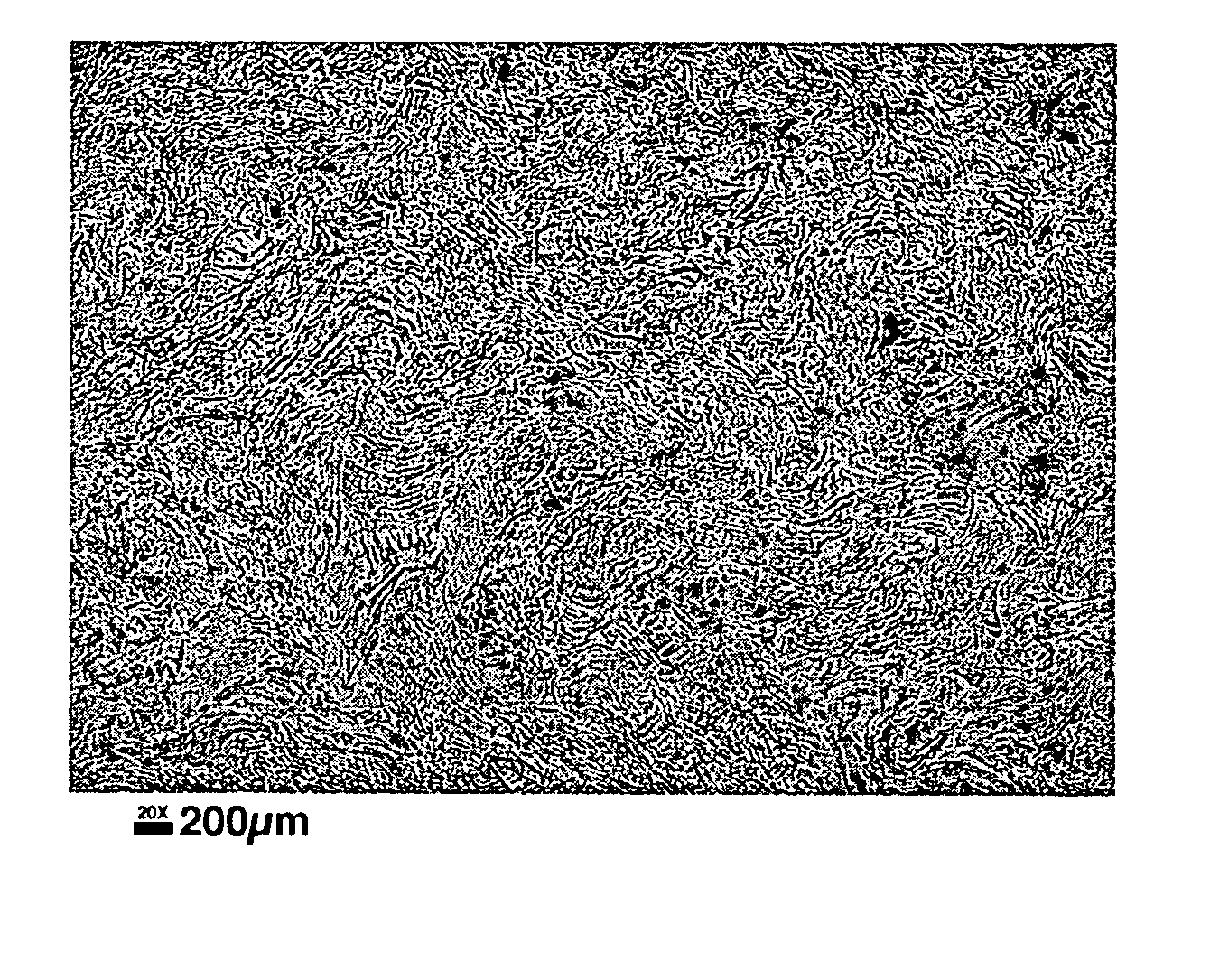

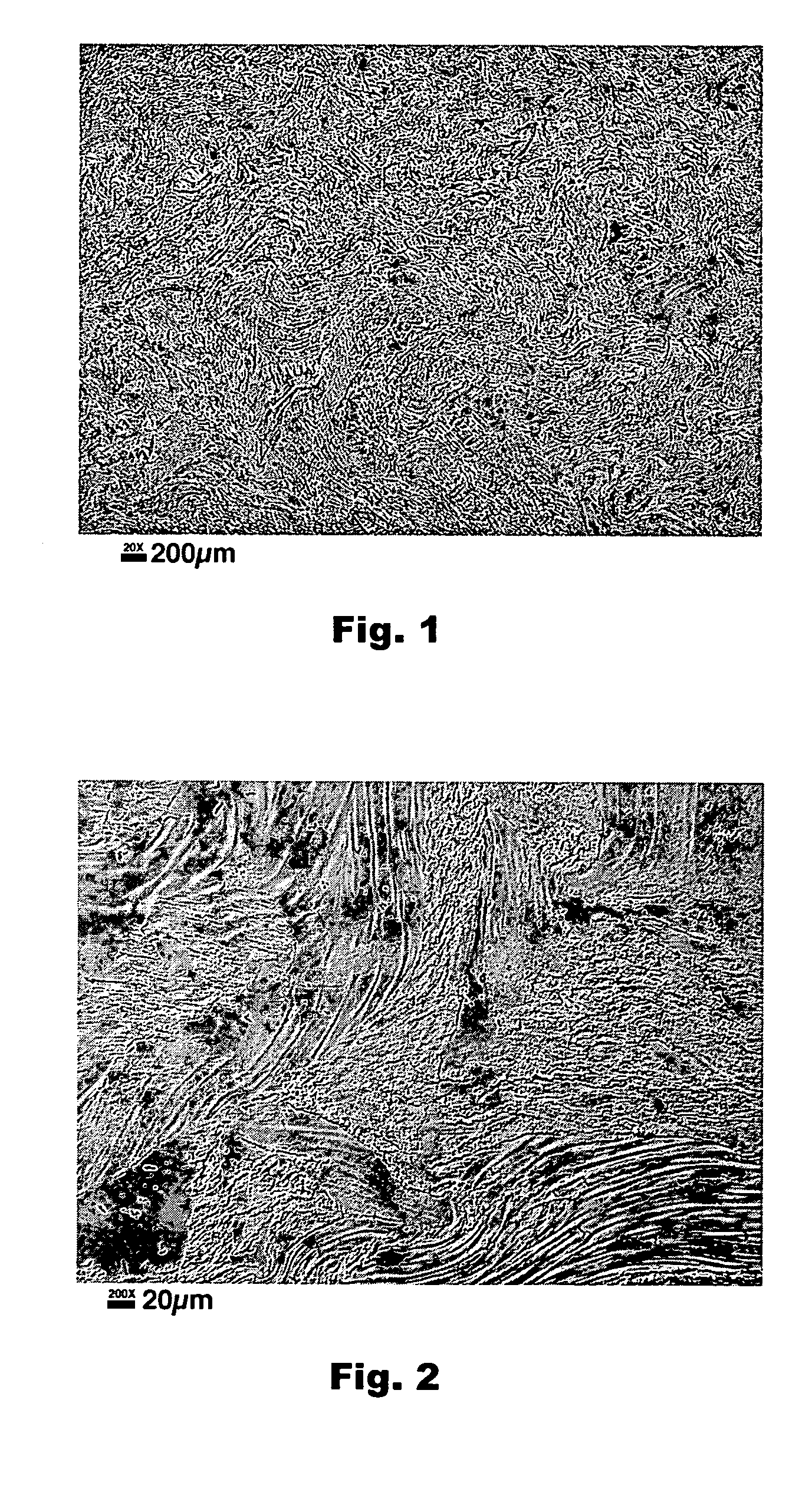

Image

Examples

example i

[0011] A tungsten alloy of nominal composition W-26% Re-0.28% Hf-0.02% C was produced by consumable vacuum arc melting of an electrode consisting of tungsten bar, electron-beam melted rhenium slugs, hafnium wire and carbon yarn. An ingot of 75-mm diameter was formed, then hot extruded with a preheat temperature of 2000° C. to bar of 37 mm diameter. The extruded bar was machined to produce a tool for use in friction stir welding. The tool was used to friction stir a length of 50 cm of stainless steel plate. The wear of the tool during the weld processing was less than 25 micrometers.

[0012] The material may also be used as a surface layer on a lower cost tool substrate material to provide the benefits of the present invention while providing a lower cost tool than one made entirely of tungsten alloy. The tungsten alloys described above can be used as surface layers on various other materials, for example, metals, alloys, cermets, and ceramics. The tungsten alloy surface layer can be ...

example ii

[0014] A tungsten alloy is prepared as described in Example I and coated onto an extrusion die by a conventional plasma spray method to form a tungsten alloy coated extrusion die.

[0015] Moreover, a tungsten alloy tool may have a surface layer of another material thereon. Suitable surface layer materials include those that are harder and / or more wear resistant than the tungsten alloys. Examples of suitable surface layer materials include but are not limited to, alone or in any combination: boron carbide, hafnium carbide, titanium carbide, niobium carbide, tantalum carbide, zirconium carbide, boron nitride, hafnium nitride, titanium nitride, niobium nitride, tantalum nitride, zirconium nitride, aluminum oxide, and hafnium oxide.

[0016] It follows that a tool having a tungsten alloy surface layer may have a further surface layer of another material thereon (as described hereinabove), with the tungsten alloy serving as an intermediate layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com