Gradient nano composite ceramic tool material and preparation method thereof

A nano-composite, ceramic tool technology, applied in the field of composite ceramic tool materials, achieves the effects of relieving residual thermal stress, improving bending strength and fracture toughness, and improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

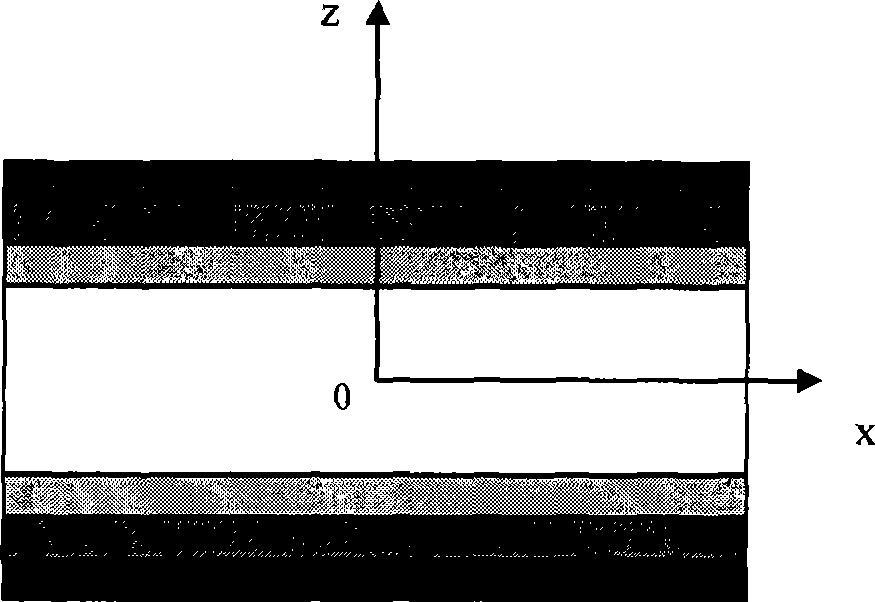

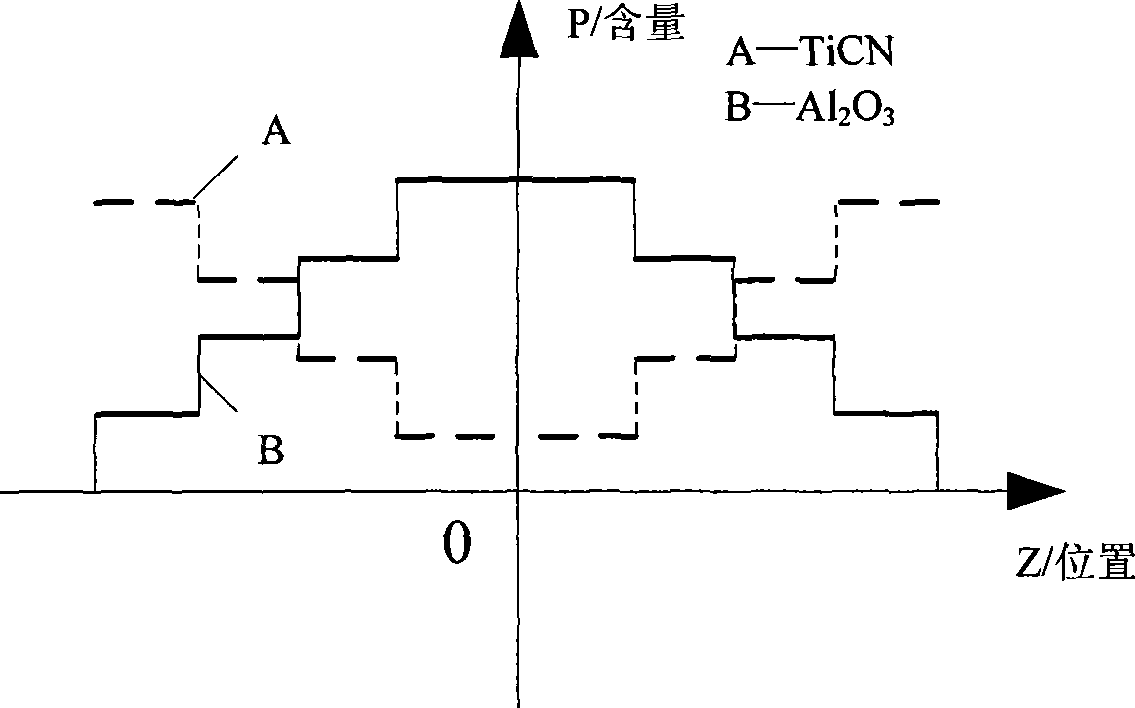

[0023] Embodiment 1, three-layer symmetrical gradient structure

[0024] The volume content of TiCN in the central layer is 35%, Al 2 o 3 The volume content is 64%, the TiCN volume content of the two surface layers is 45%, Al 2 o 3 The volume content is 54%, the surface layer of nano-Al 2 o 3 Occupies the layer Al 2 o 3 20% of the total, MgO, Y in each layer 2 o 3 And the total volume content of NiO is 1%. Use deionized water as the dispersion medium to prepare nano-Al 2 o 3 The mass fraction is 0.2% suspension, adding relative nanometer Al 2 o 3 The dispersant of 2% by mass is sodium hexametaphosphate as the dispersant. Disperse on an ultrasonic dispersing mixer for 10 to 30 minutes, then remove the solution from the ultrasonic dispersing machine; adjust the pH value of the suspension to 7 to 11 to make the suspension alkaline. Micron Al 2 o 3 And TiCN and MgO, Y 2 o 3 , NiO and prepared nano-Al 2 o 3 Mix the suspension, disperse it on an ultrasonic disper...

Embodiment 2

[0026] Embodiment 2, three-layer symmetrical gradient structure

[0027] The TiCN content of the central layer is 30%, Al 2 o 3 The TiCN content of the two surface layers is 69%, the TiCN content of the two surface layers is 40%, and the Al 2 o 3 The content is 59%, the surface layer of nano-Al 2 o 3 Occupies the layer Al 2 o 3 10% of each layer of MgO, Y 2 o 3 And the total volume content of NiO is 1%. Using absolute alcohol as the dispersion medium, prepare nano-Al 2 o 3 The mass fraction is 0.2% suspension, adding relative nanometer Al 2 o 3 A dispersant with a mass of 0.1% uses sodium polyphosphate as a dispersant. When the powder is layered and filled, the ratio of the sum of the thicknesses of the two surface layers to the total thickness is 0.1. All the other processes are the same as in Example 1.

[0028] The mechanical properties of the prepared gradient nanocomposite tool material are: hardness HV18.6~19.4GPa, bending strength 710~800MPa, fracture tou...

Embodiment 3

[0029] Embodiment 3, three-layer symmetrical gradient structure

[0030] The TiCN content of the central layer is 50%, Al 2 o 3 The TiCN content of the two surface layers is 49%, the TiCN content of the two surface layers is 60%, and the Al 2 o 3 The content is 39%, the surface layer of nano-Al 2 o 3 Occupies the layer Al 2 o 3 30% of the total, MgO, Y of each layer 2 o 3 And the total volume content of NiO is 1%. Using absolute alcohol as the dispersion medium, prepare nano-Al 2 o 3 The mass fraction is 0.2% suspension, adding relative nanometer Al 2 o 3 A dispersant of 3% by mass, using sodium silicate as a dispersant. When the powder is layered and filled, the ratio of the sum of the thicknesses of the two surface layers to the total thickness is 0.5. All the other processes are the same as in Example 1.

[0031] The mechanical properties of the prepared gradient nanocomposite tool material are: hardness HV18.0~18.6GPa, bending strength 850~940MPa, fracture t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com