PCD tool cutting edge processing method

A processing method and cutting tool technology, which are applied in the accessories of tool holders, metal processing equipment, and cutting tools for lathes, etc., can solve the problems of difficult grinding, expensive grinding wheels, and high hardness of PCD materials, so as to improve cutting edge processing The effect of speed, shortened production cycle, and shortened processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

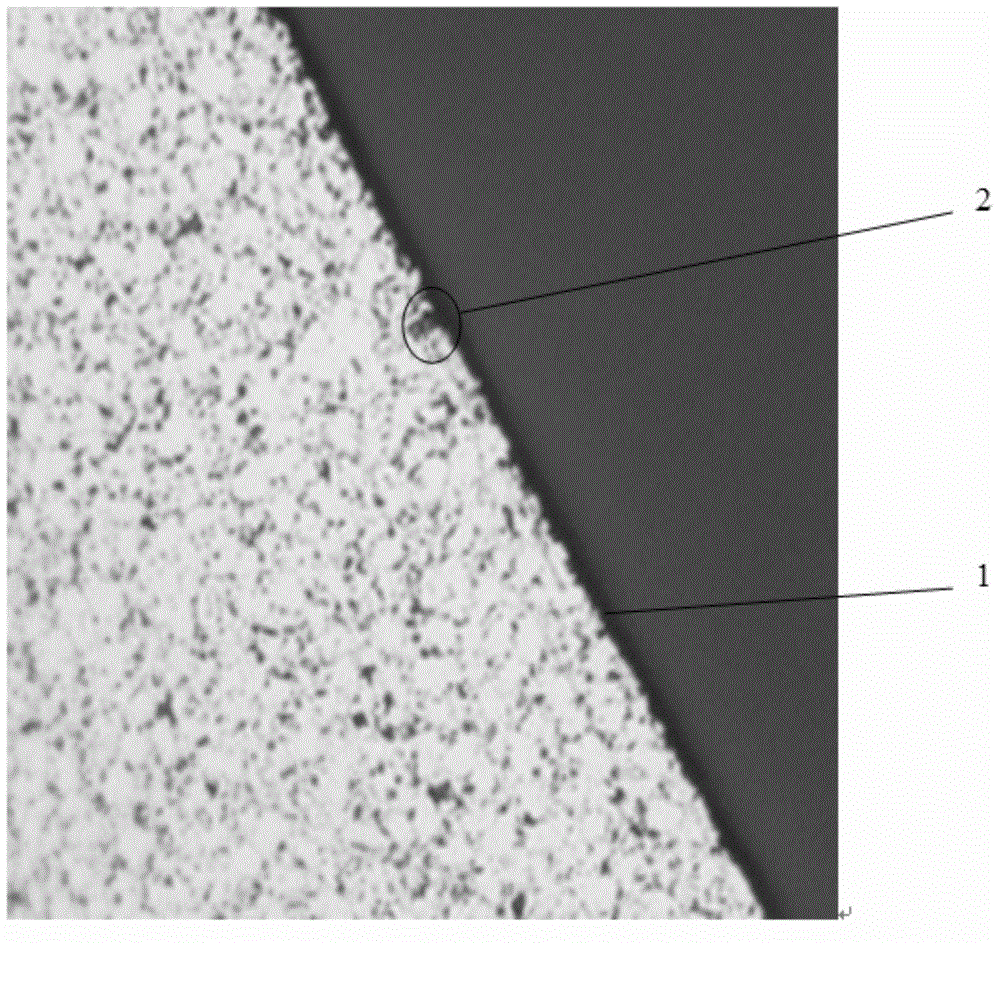

Image

Examples

Embodiment 1

[0031] A kind of processing method of PCD cutter edge, comprises the following steps:

[0032] 1) Cut a whole piece of PCD composite sheet with a diameter of 76.00mm by wire-cutting slow-moving method, and cut it into several PCD blades of 3.5*12mm according to the requirements.

[0033] 2) Blade welding: place the PCD blade in a vacuum drying oven at 450°C for 1 hour, then take out the PCD blade, and use a high-frequency induction welding machine to weld the PCD blade to the WC / Co cemented carbide, and then weld the PCD blade to the WC / Co cemented carbide. The tool was slowly cooled to room temperature to obtain a PCD tool.

[0034] 3) Edge treatment of the PCD cutter: According to the design requirements of the cutter shape, the PCD cutter is laser cut by a laser cutting device to obtain a PCD cutter with a smooth cutting edge. Among them, the processing parameters of the laser cutting process are: laser power 40%, laser width 0.1mm, laser taper 0°, line speed 50mm / min, cut...

Embodiment 2

[0037] The characteristics of this embodiment are: the processing parameters of the laser cutting process are: laser power 50%, laser width 0.1mm, laser taper 0°, linear speed 100mm / min, cutting step distance 0.05mm, cutting depth 0.01mm. Others are the same as in Example 1.

Embodiment 3

[0039] The characteristics of this embodiment are: the processing parameters of the laser cutting process are: laser power 60%, laser width 0.2mm, laser taper 0°, linear speed 100mm / min, cutting step distance 0.05mm, cutting depth 0.05mm. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com