Diamond coating silicon nitride ceramic integral cutter, preparation method thereof and application of cutter in graphite

A technology of silicon nitride ceramics and diamond coating, applied in metal material coating technology, coating, stone processing equipment, etc., can solve the problems of brittle graphite that is easy to break and deform, high processing and manufacturing costs, and difficult to guarantee quality , to achieve excellent wear resistance and chemical stability, to solve the effect of easy tool wear and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

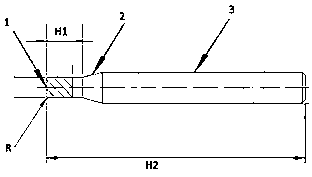

[0040] A diamond-coated silicon nitride ceramic integral tool in this embodiment, the tool is composed of a silicon nitride ceramic substrate and a diamond film coating, the diamond film coating is applied on the surface of the silicon nitride ceramic substrate, and the diamond The thickness of the thin film coating is 10 μm.

[0041] The chemical vapor deposition (CVD) diamond film of this embodiment has extremely high hardness, excellent wear resistance and chemical stability due to its excellent chemical and physical properties. Combining the advantages of the coating material and the ceramic cutting tool substrate, the diamond-coated silicon nitride ceramic integral tool has good cutting performance, extremely high hardness and wear resistance, low friction coefficient,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com