Antimicrobial ceramic cutting tool and its manufacturing method

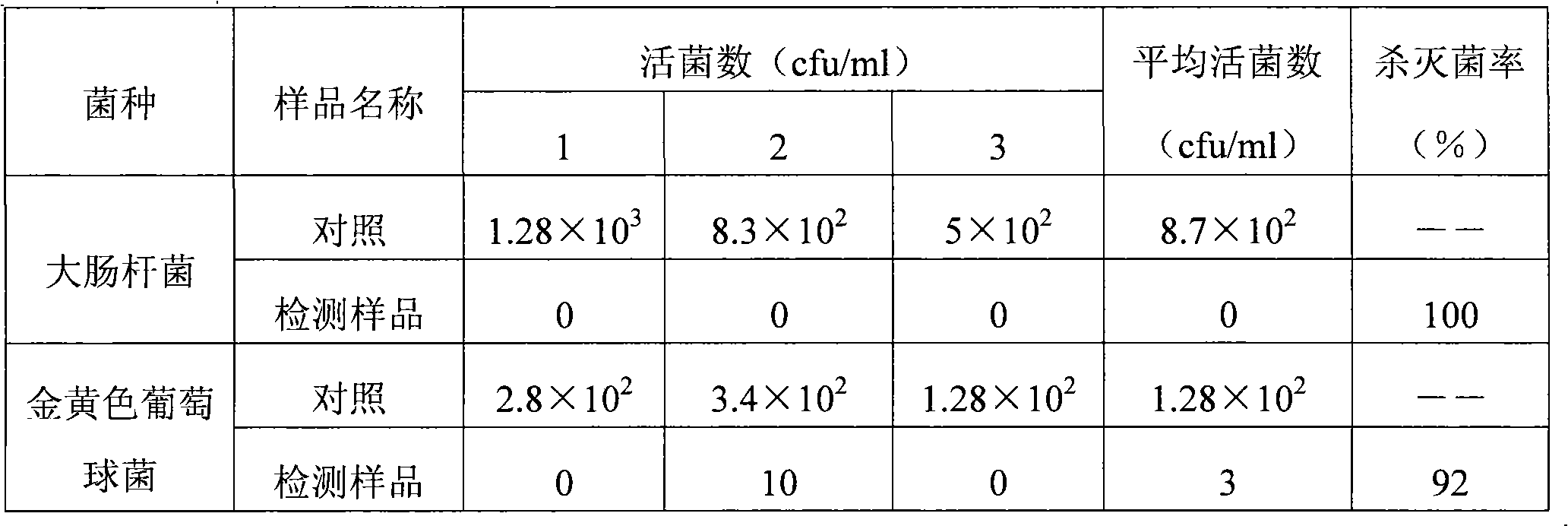

A technology for antibacterial ceramics and ceramic knives, applied in the field of fine ceramics, can solve the problems of precious metal silver, affecting safety, heavy metal ions entering food, etc., and achieve excellent antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Raw materials: ultra-fine zirconia powder (specific surface area less than 8 square meters, particle size 5-10 μm. Provided by Zibo Chenyuan Powder Co., Ltd.) 95Kg, multifunctional healthy ceramic material (self-prepared) 5Kg. Wherein the multifunctional healthy ceramic material is prepared according to the content disclosed in the CN1190390C patent.

[0043] 2) preparation method, comprises the steps:

[0044] Evenly mix ultra-fine zirconia powder with multi-functional healthy ceramic materials, add appropriate amount of water, wet finely grind for 1-2 hours, spray granulation; form by isostatic pressing at 150-200MPa, and fire at a high temperature of 1600°C 5-12 hours, and then grind and process to make ceramic fruit knives.

Embodiment 2

[0046] 1) Raw materials: Sialon ceramic powder (with a particle size of 1-10um, provided by Lucas AyMon, UK.) 97Kg, multifunctional healthy ceramic powder (self-provided) 3Kg.

[0047] 2) The preparation method is basically the same as in Example 1, except that the firing temperature is 1450-1500° C., and ceramic kitchen knives are obtained through different molding processes.

Embodiment 3

[0049] 1) Raw materials: 99Kg of titanium carbide-based cermet material (prepared according to the technical scheme disclosed in Chinese patents CN1271706A and CN1477222A), 1Kg of antibacterial material (self-prepared).

[0050]2) The preparation method is basically the same as in the examples, except that the firing temperature is 1600-1850° C., and the ceramic western-style knife is obtained through different molding processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com