Antibacterial ceramic cutting tool and preparation method thereof

A technology of antibacterial ceramics and knives, applied in the field of ceramics, can solve problems such as high cost, easy to be oxidized, precious metal silver, etc., and achieve good antibacterial, good resistance and inhibition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

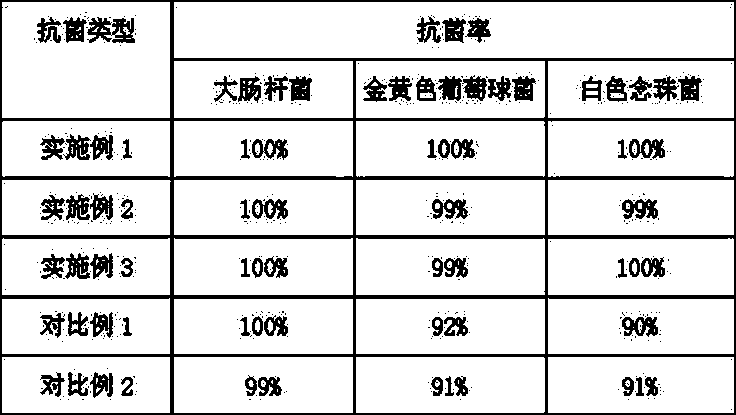

Examples

preparation example Construction

[0038] In addition, the present invention also provides a kind of preparation method of antibacterial ceramic cutter, comprises the following steps:

[0039] S1, batching, ceramic material and antibacterial active material are mixed according to the above-mentioned ratio, and the mixed material of ceramic material and antibacterial active material is obtained;

[0040] S2. Perform ball milling operation on the mixed material of ceramic material and antibacterial active material prepared in step S1 to obtain the mixed material after ball milling;

[0041] S3, subjecting the ball-milled mixed material prepared in step S2 to molding processing to obtain a molding blank;

[0042] S4, subjecting the molded blank prepared in step S3 to isostatic pressing to obtain an isostatic pressed blank;

[0043] S5. Sintering the isostatic pressing blank obtained in step S4 to obtain a ceramic cutting tool blank;

[0044] S6, post-processing to obtain ceramic cutters.

[0045] In above-menti...

Embodiment 1

[0060] 1. Raw material: 90kg of superfine zirconia powder doped with 3wt% yttrium oxide, 10kg of antibacterial active material.

[0061] 2. Antibacterial active material 10kg is prepared according to the following ratio: potassium feldspar 32wt%, marble 5wt%, silica 7wt%, zeolite 11wt%, silver oxide 10wt%, titanium dioxide 10wt%, copper oxide 10wt%, oxidation 15wt% of aluminum is based on the total mass of materials required for the preparation of antibacterial active materials.

[0062] Preparation:

[0063] 1) Put potassium feldspar, marble, silica, zeolite, silver oxide, titanium dioxide, copper oxide, aluminum oxide, carboxymethyl cellulose and water into a ball mill in turn for ball milling, pass through a 325-mesh sieve to make a slurry.

[0064] 2) The above slurry is grouted into blocks, and sintered at a temperature of 1200 ° C for 1 hour to remove carboxymethyl cellulose and water.

[0065] 3) Crushing, passing through a 200-mesh sieve, and performing secondary ba...

Embodiment 2

[0070] 1. Raw materials: 97kg of silicon nitride whisker toughened ceramic material, 3kg of nano antibacterial active material.

[0071] 2, nano antibacterial active material is prepared antibacterial active material 3kg by following proportioning: Potassium feldspar 34wt%, marble 5wt%, silica 40wt%, zeolite 5wt%, silver oxide 2wt%, titanium dioxide 2wt%, copper oxide 2wt%, Aluminum oxide 10wt%.

[0072] Preparation:

[0073] 1) Put potassium feldspar, marble, silica, zeolite, silver oxide, titanium dioxide, copper oxide, aluminum oxide, carboxymethyl cellulose and water into a ball mill in turn for ball milling, pass through a 325-mesh sieve to make a slurry.

[0074] 2) Grout the above slurry into blocks, sinter at 1300°C for 1.5h, remove carboxymethyl cellulose and water

[0075] 3) Crushing, passing through a 200-mesh sieve, and performing secondary ball milling to obtain antibacterial active materials.

[0076] After determination, the composition and ratio of the nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com