Ceramic cutting tool material with high mechanical strength and preparation method therefor

A technology of mechanical strength and ceramic knives, applied in the field of ceramic materials, can solve the problems of limited wear resistance, poor thermal shock resistance, poor heat dissipation, etc., achieve improved corrosion resistance and heat resistance, long service life, and improve the overall mechanical The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

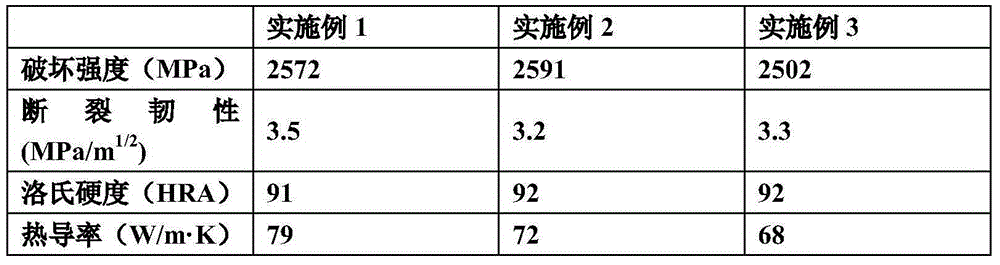

Embodiment 1

[0016] A ceramic tool material with high mechanical strength, made of the following raw materials by weight (kg): silicon dioxide 50, nano-alumina 10, yellow rust stone 6, sodium fluoride 1, polyacrylic acid 1, magnesium borate whisker 2 , fly ash 15, glycerin 2, triglycidyl ester 3, borate coupling agent 4, antimony trichloride 2, phosphorus pentoxide 1, phenolic resin emulsion 2, butanediol 2, additive 6;

[0017] The auxiliary agent is made of the following weight (kg) raw materials: boorite 8, blast furnace slag 20, copper oxide 4, styrene-butadiene rubber latex 2, gypsum 3, sodium tripolyphosphate 1, brucite fiber 1, bovine bone 2. Calcium dihydrogen phosphate 2, dipropylene glycol 2; the preparation method is: add boronite, blast furnace slag, copper oxide, gypsum, brucite fiber, and bovine bone to the mixer, add styrene-butadiene rubber latex, three Sodium polyphosphate, calcium dihydrogen phosphate, dipropylene glycol and water are wet mixed, and after 2 hours, the mix...

Embodiment 2

[0024] A ceramic knife material with high mechanical strength, made of the following raw materials by weight (kg): silicon dioxide 60, nano-alumina 11, yellow rust stone 7, sodium fluoride 1, polyacrylic acid 2, magnesium borate whisker 3 , fly ash 20, glycerin 2, triglycidyl ester 4, borate coupling agent 5, antimony trichloride 3, phosphorus pentoxide 1, phenolic resin emulsion 3, butanediol 2, additive 7; The above additives are made of the following weight (kg) raw materials: boorite 10, blast furnace slag 22, copper oxide 5, styrene-butadiene rubber latex 3, gypsum 4, sodium tripolyphosphate 1, brucite fiber 2, bovine bone 3 , calcium dihydrogen phosphate 2, dipropylene glycol 2; the preparation method is: add boronite, blast furnace slag, copper oxide, gypsum, brucite fiber, and bovine bone to the mixer, add styrene-butadiene rubber latex, terpolymer Sodium phosphate, calcium dihydrogen phosphate, dipropylene glycol and water are wet mixed, and after 2.5 hours, the mixed...

Embodiment 3

[0031] A ceramic knife material with high mechanical strength, made of the following raw materials by weight (kg): silicon dioxide 70, nano-alumina 12, yellow rust stone 8, sodium fluoride 2, polyacrylic acid 2, magnesium borate whisker 4 , fly ash 25, glycerin 3, triglycidyl ester 5, borate coupling agent 6, antimony trichloride 4, phosphorus pentoxide 2, phenolic resin emulsion 3, butanediol 4, additive 7;

[0032] The auxiliary agent is made of the following weight (kg) raw materials: boorite 12, blast furnace slag 24, copper oxide 6, styrene-butadiene rubber latex 4, gypsum 5, sodium tripolyphosphate 2, brucite fiber 3, bovine bone 4. Calcium dihydrogen phosphate 3, dipropylene glycol 4; the preparation method is: add boronite, blast furnace slag, copper oxide, gypsum, brucite fiber, and bovine bone to the mixer, add styrene-butadiene rubber latex, three Sodium polyphosphate, calcium dihydrogen phosphate, dipropylene glycol and water are wet mixed, and after 3 hours, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com