Preparation method of silicon nitride-based conductive ceramic and molding method of silicon nitride-based conductive ceramic cutting tool

A conductive ceramic, silicon nitride-based technology, applied in the field of ceramic preparation, can solve the problems of high brittleness, poor electrical properties of silicon nitride ceramics, difficult processing, etc., to improve toughness and strength, reduce tool processing costs, and relax sintering process. The effect of the restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-23

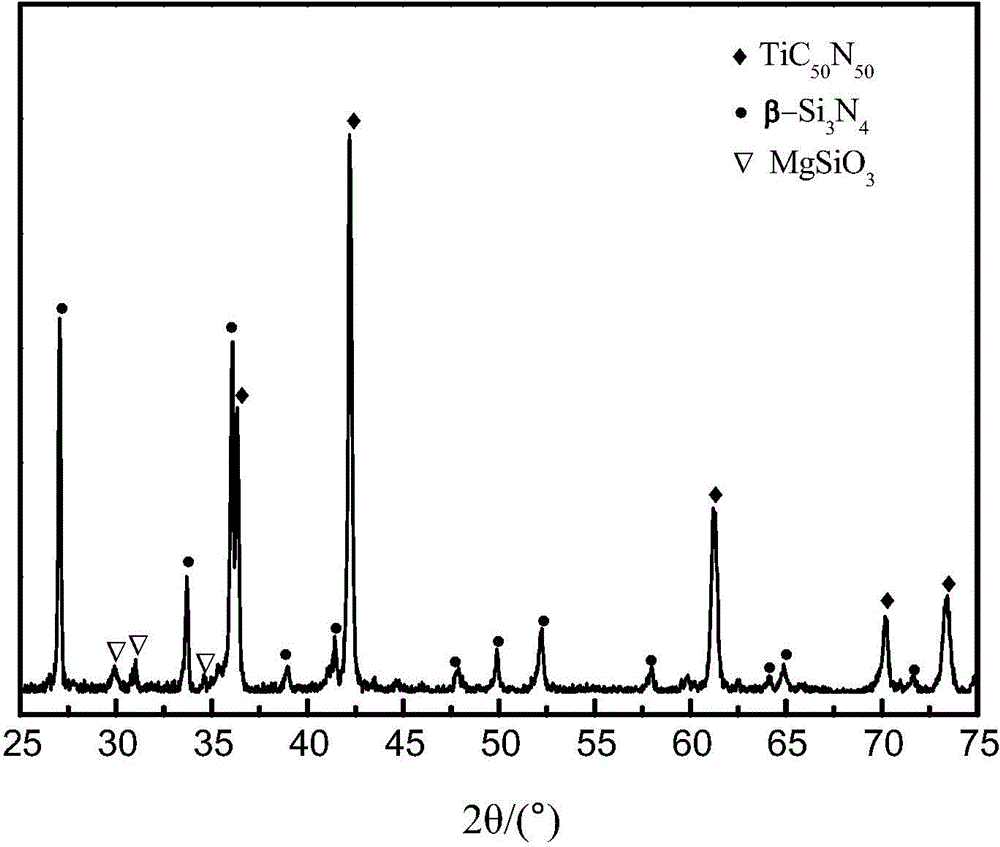

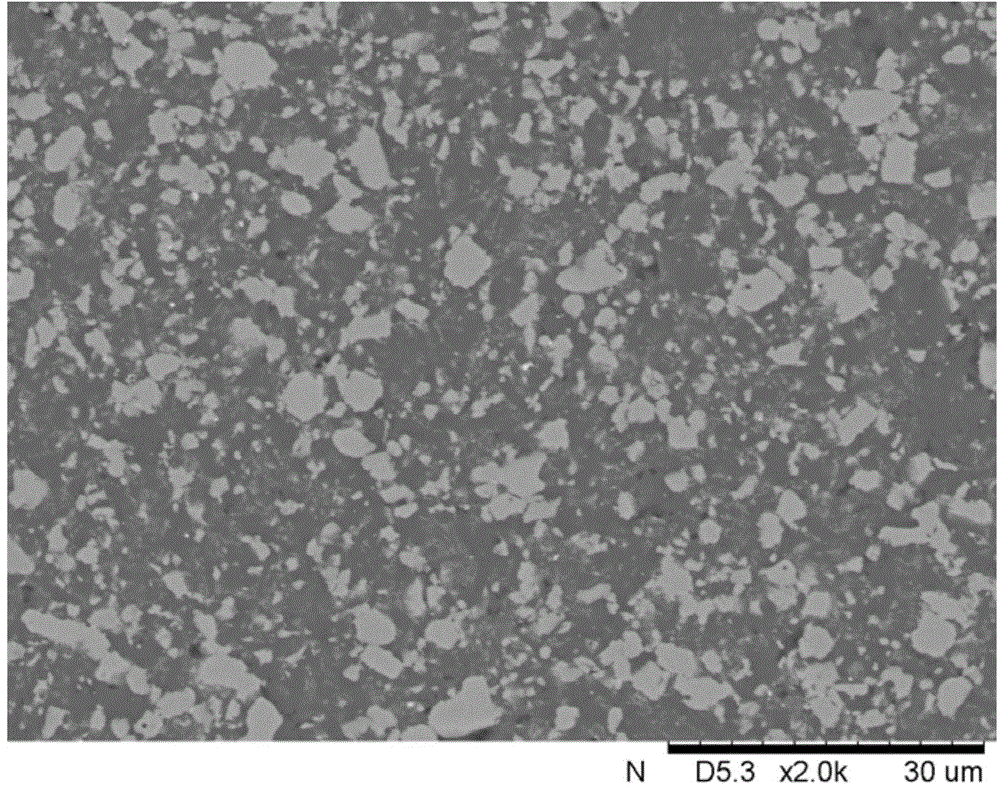

[0027] The preparation method of silicon nitride-based conductive ceramics is as follows:

[0028] (1) Ingredients: Take Si as the volume percentage shown in Table 1 below 3 N 4 Powder, conductive phase, binder and sintering aids, and then the selected components are mixed together to obtain mixed raw materials.

[0029] (2) Mixing: Mix the mixed raw materials with absolute ethanol, the volume percentage of the solid phase is 35%; after mixing, place the mixture in a planetary ball mill for high speed (400r / min) ball milling for 20 hours, and then ultrasonically disperse the mixture for 4 minutes; Get mixed slurry. Then, the mixed slurry is placed at 60°C by rotary evaporation to remove most of the absolute ethanol, and then the mixed slurry is dried at 80°C and passed through a 100-mesh sieve to obtain a mixed powder.

[0030] (3) High temperature sintering

[0031] High-temperature sintering method one (Example 1-19, Example 22-23): Place the mixed powder in the mold at 1atm of N 2...

Embodiment 24

[0046] The preparation methods of silicon nitride-based conductive ceramics and silicon nitride-based conductive ceramic tools are as follows:

[0047] (1) Ingredients: respectively take 67% vol Si according to volume percentage 3 N 4 Powder, 30%vol TiC 0.5 N 0.5 , 3%volMgO-Y 2 O 3 , And then mix the three components together to get mixed raw materials.

[0048] (2) Mixing: mix the mixed raw materials with anhydrous ethanol, the volume percentage of the solid phase is 35%; after mixing, place the mixture in a planetary ball mill for high speed (400r / min) ball milling for 20 hours, and then perform 3min ultrasound on the mixture Disperse; get mixed slurry. Next, the mixed slurry is placed at 60° C. to remove most of the absolute ethanol by rotary evaporation, and then the mixed slurry is dried at 80° C. and passed through a 100-mesh sieve to obtain a mixed powder.

[0049] (3) High-temperature sintering: place the mixed powder in the mold, at 1atm of N 2 Under the atmosphere, hot pre...

Embodiment 25

[0055] The preparation methods of silicon nitride-based conductive ceramics and silicon nitride-based conductive ceramic tools are as follows:

[0056] (1) Ingredients: take 67.5% vol Si by volume percentage 3 N 4 Powder, 27.5%vol TiC 0.5 N 0.5 , 5%volMgO-Y 2 O 3 , And then mix the three components together to get mixed raw materials.

[0057] (2) Mixing: Mix the mixed raw materials with absolute ethanol, the volume percentage of the solid phase is 35%; after mixing, place the mixture in a planetary ball mill for high speed (400r / min) ball milling for 20 hours, and then conduct the mixture for 4.5 minutes Ultrasonic dispersion; get mixed slurry. Next, the mixed slurry is placed at 60° C. to remove most of the absolute ethanol by rotary evaporation, and then the mixed slurry is dried at 80° C. and passed through a 100-mesh sieve to obtain a mixed powder.

[0058] (3) High-temperature sintering: place the mixed powder in the mold, at 1atm of N 2 In the atmosphere, the two-step heat pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com