Ceramic cutting tool cutting parameter optimization method on interrupted cutting conditions

A technology of cutting parameters and ceramic tools, which is applied in the direction of electric digital data processing, special data processing applications, instruments, etc., can solve problems such as difficulty in ensuring high cutting parameter optimization accuracy, achieve high optimization accuracy, improve tool life, and reduce optimization. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

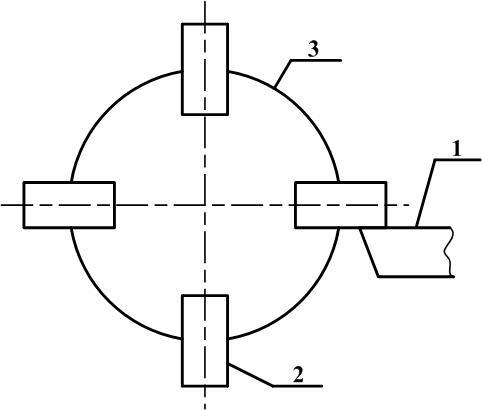

[0033] A method for optimizing cutting parameters of a ceramic tool under interrupted cutting conditions of the present invention comprises the following steps:

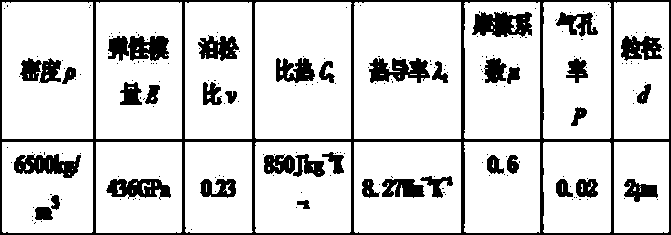

[0034] (1), first determine the macroscopic physical performance parameters and microstructural parameters of ceramic cutting tools;

[0035] (2) Determine the initial state value and critical state value of the microscopic damage of ceramic tools through theoretical calculation methods;

[0036] (3) Determine the physical performance parameters of the workpiece material and the parameters of the Johnson-Cook constitutive model;

[0037] (4) Set the geometry of the tool and the workpiece in the finite element simulation software, and import the relevant parameters of the tool material and workpiece material;

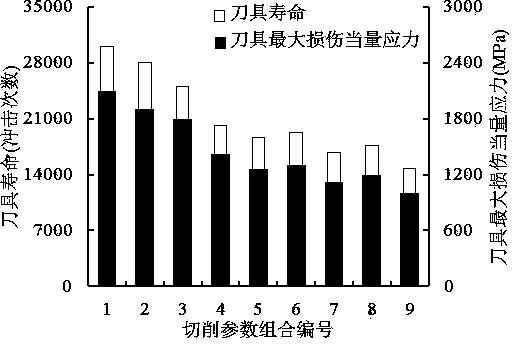

[0038] (5) According to the actual processing conditions, the combination of cutting parameters used in the finite element simulation process is determined by the orthogonal experimental design method, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com