Aluminum oxide reinforced high-entropy boride ceramic as well as preparation method and application thereof

A technology of borides and alumina, which is applied in the field of alumina-enhanced high-entropy boride ceramics and its preparation, can solve problems that have not been reported in the application, and achieve grain growth inhibition, good high-temperature strength and hardness, and good wear resistance The effect of sex and machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

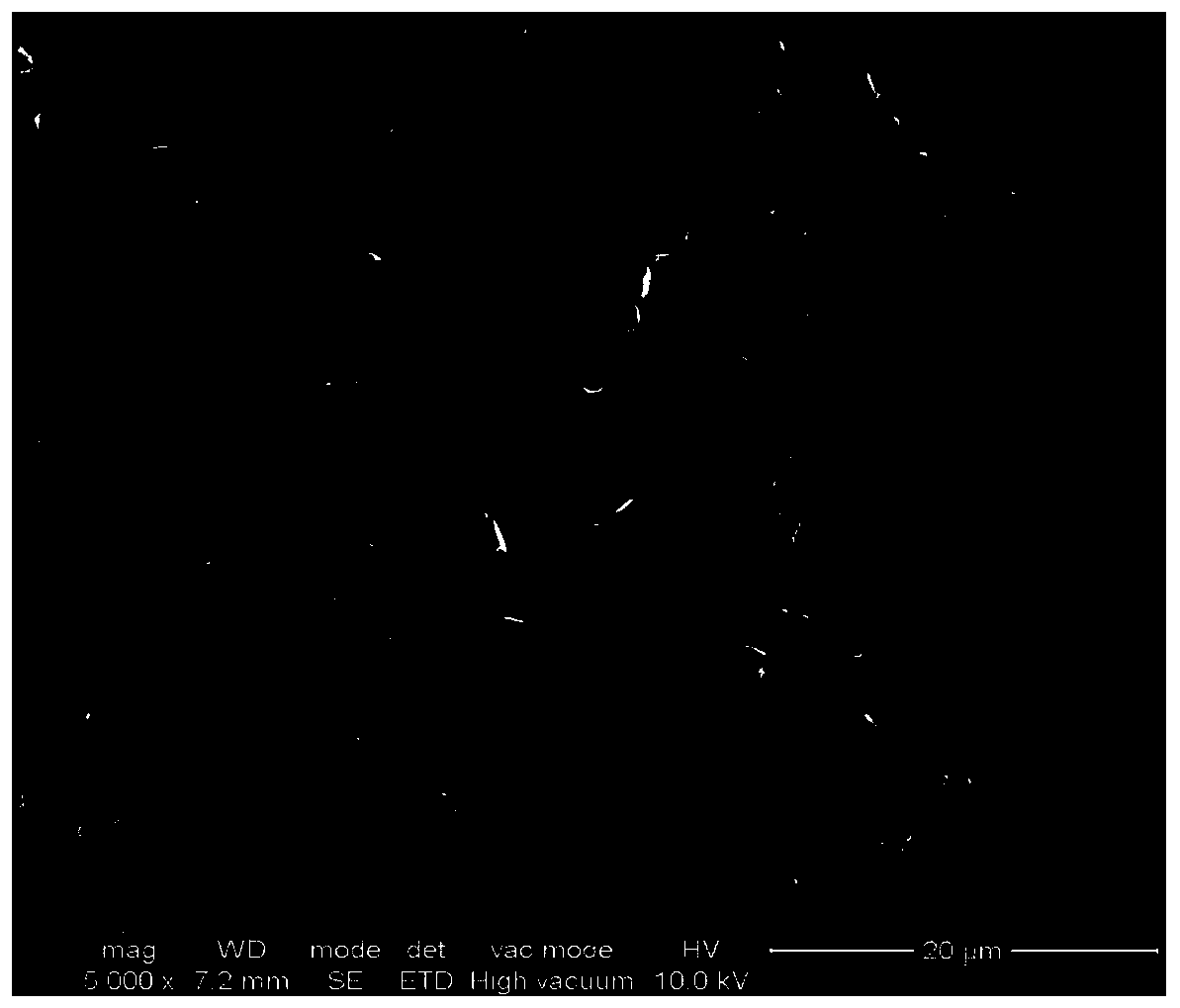

Embodiment 1

[0029] 1. Preparation:

[0030] (1) With (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 Powder is (particle size 2 O 3 Powder (purity is 99.5%, particle size is 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 : Al 2 O 3 The volume ratio is 80:20 for batching, ethanol is used as solvent, cemented carbide Al 2 O 3 The ball is the ball milling medium. After the planetary ball mill is mixed at 300r / min for 24h, a uniformly mixed (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Al 2 O 3 Powder.

[0031] (2) Put (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Al 2 O 3 The mixed powder is put into the graphite mold of the spark plasma sintering furnace, heated to 900°C at a rate of 300°C / min under the vacuum condition of less than 1mbar, and then filled with 1atm argon within 1min. After the filling is completed, within 2min The inner axis is pressurized to 40MPa, and at the same time as the inflation starts, the temperature is increased to 1800°C at a rate of 100°C / min, and the temperature is kept for 15 minutes. Afte...

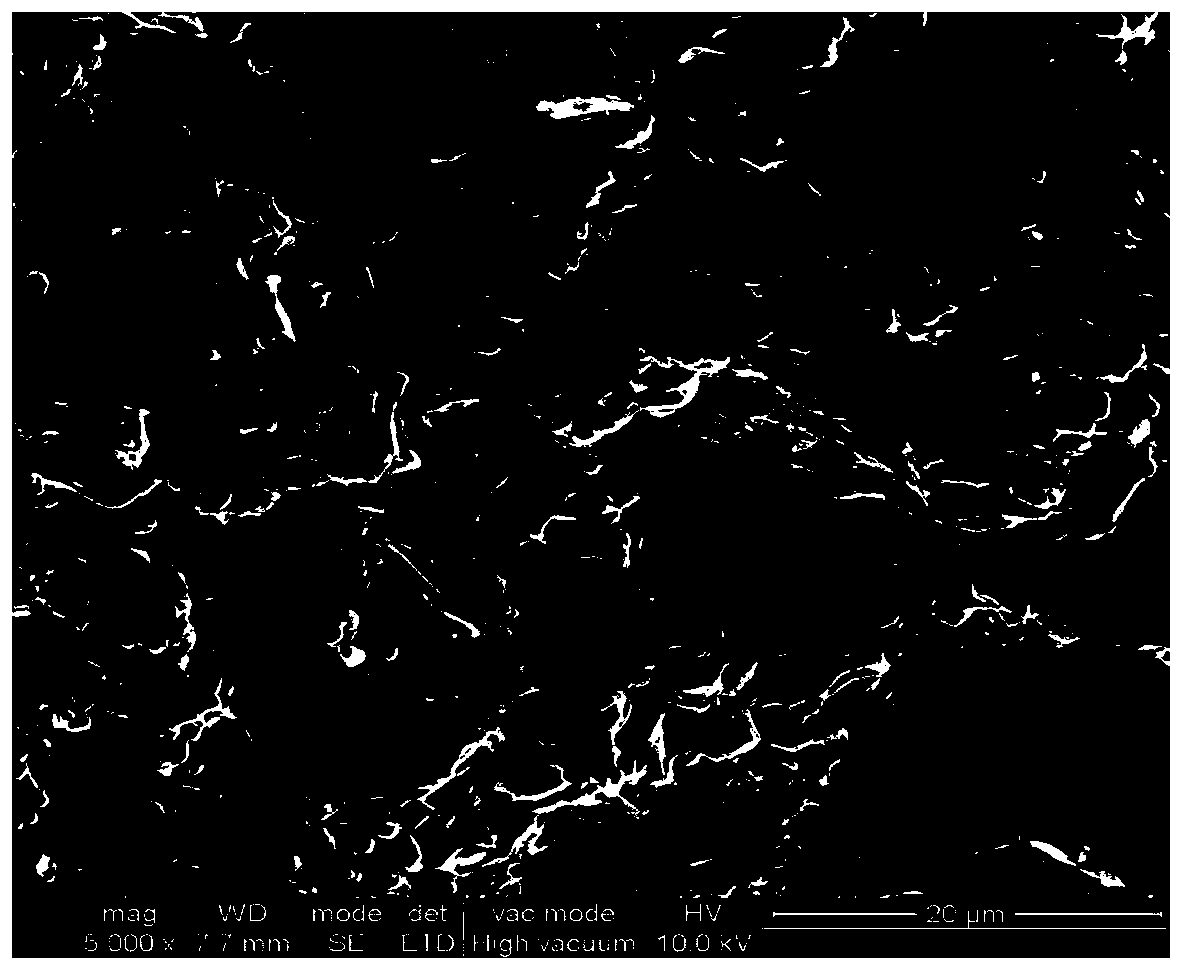

Embodiment 2

[0038] 1. Preparation:

[0039] (1) With (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 Powder is (particle size 2 O 3 Powder (purity 99.5%, particle size 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 : Al 2 O 3 The volume ratio is 75:25 for batching, ethanol is used as solvent, and cemented carbide Al 2 O 3 The ball is the ball milling medium. After the planetary ball mill is mixed at 300r / min for 24h, a uniformly mixed (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Al 2 O 3 Powder.

[0040] (2) Put (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Al 2 O 3 The mixed powder is put into the graphite mold of the spark plasma sintering furnace, heated to 900°C at a rate of 300°C / min under the vacuum condition of less than 1mbar, and then filled with 1atm argon within 1min. After the filling is completed, within 2min The inner axial pressure is increased to 30MPa, and at the same time the inflation starts, the temperature is increased to 1900°C at a rate of 100°C / min, and the temperature is kept for 10 minutes. A...

Embodiment 3

[0043] 1. Preparation:

[0044] (1) With (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 Powder is (particle size 2 O 3 Powder (purity 99.5%, particle size 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 : Al 2 O 3 The volume ratio is 85:15 for batching, ethanol is used as solvent, and cemented carbide Al 2 O 3 The ball is the ball milling medium. After the planetary ball mill is mixed at 300r / min for 24h, a uniformly mixed (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Al 2 O 3 Powder.

[0045] (2) Put (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Al 2 O 3 The mixed powder is put into the graphite mold of the spark plasma sintering furnace, heated to 900°C at a rate of 300°C / min under the vacuum condition of less than 1mbar, and then filled with 1atm argon within 1min. After the filling is completed, within 2min The inner axial pressure is increased to 35MPa, and at the same time the inflation is started, the temperature is increased to 1900°C at a rate of 100°C / min, and the temperature is kept for 15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com