Methods for preparing multiphase high-strength highly-wear-resistant silicon nitride ceramic cutting tool material and tool

A technology of silicon nitride ceramics and cutting tool materials, which is applied in the accessories of tool holders, cutting tools for lathes, turning equipment, etc., and can solve the problems of the impact of material compactness and insufficient wear resistance of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The weight percentage (hereinafter referred to as wt%) is 89% α-Si3N4 powder, 1% is β-Si 3 N 4 Seed crystals and 8% of different rare earth oxide sintering aids, and different weight percentages of sub-densification aids (see Table 1 for details), mix the mixed powder with alcohol, ball mill for 48-80 hours, and dry , through a 100-mesh sieve, and then put it into a graphite grinding tool, under the pressure of 10-15MPa in a hot-pressed sintering furnace, 2 Warm up to 1750-1800°C for 20-40min, anneal at 1350°C for 1 hour, cool down to room temperature and process into required test samples, mirror polish, measure strength and hardness, and obtain sample results (see Table 2 for details).

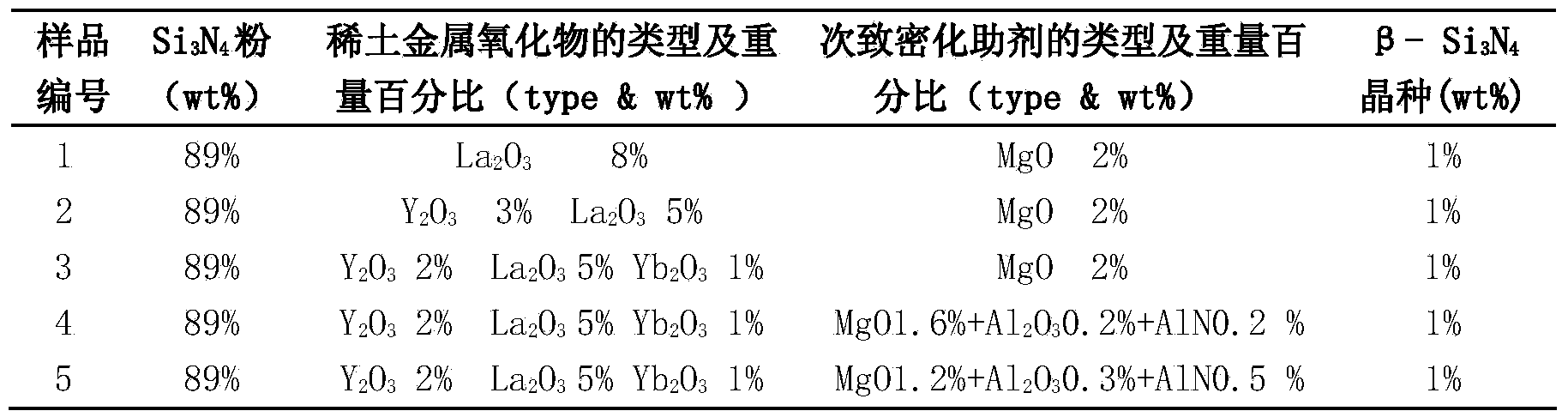

[0037] Table 1

[0038]

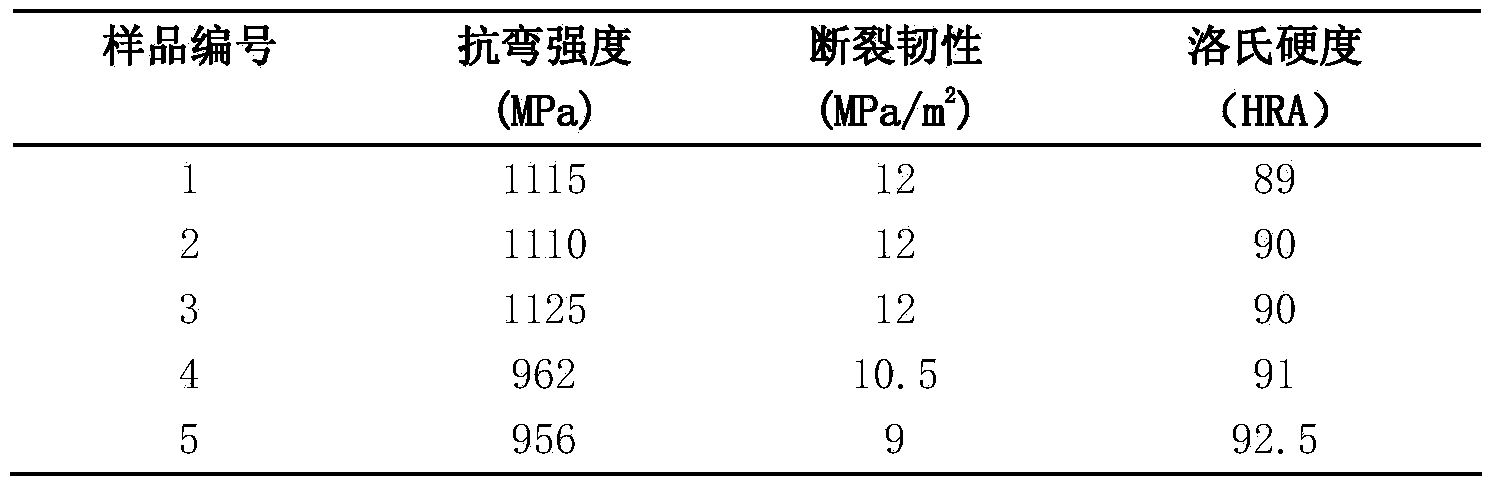

[0039] Table 2

[0040]

Embodiment 2

[0042] Different weight percentages of α-Si 3 N 4 Powder, 1% β-Si 3 N 4 Seed crystals are mixed with different weight percentages of rare earth metal oxide sintering aids and corresponding weight percentages of sub-densification aids (see Table 3 for details), ball milled, dried, sieved, put into graphite grinding tools, and heated Under the pressure of 10-15MPa in the pressure sintering furnace, under N 2 Warm up to 1750-1800°C for 30-60min, then anneal at 1350°C for 1 hour, cool down to room temperature and process into required test samples, mirror polished, and measure strength and hardness (see Table 4 for details).

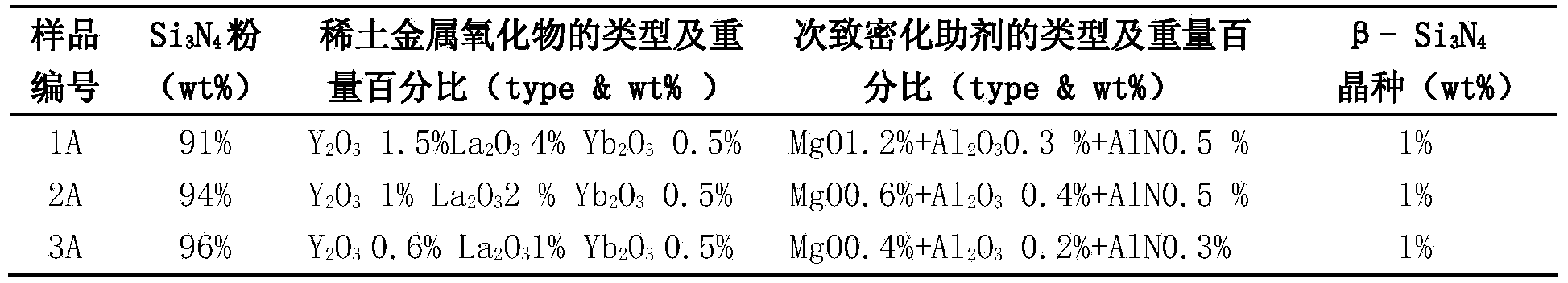

[0043] table 3

[0044]

[0045] Table 4

[0046]

Embodiment 3

[0048] The powders of samples 1, 5, 2A, and 3A were ball-milled, dried, sieved, and put into graphite grinding tools. 2 Rapidly raise the temperature to 1400°C-1450°C for 1min, then raise the temperature to 1750-1800°C for 20-40min, anneal at 1350°C for 1h, cool down to room temperature and process into required test samples, mirror polished, measure strength and hardness , (see Table 5 for details).

[0049] table 5

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com