Anisotropic graphene-toughened Al2O3 nano composite ceramic cutting tool material and preparation method thereof

A nano-composite and anisotropic technology, applied in the field of graphene toughened A12O3 nano-composite ceramic tool materials and its preparation, to achieve the effect of graphene toughening effect, convenient operation, and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

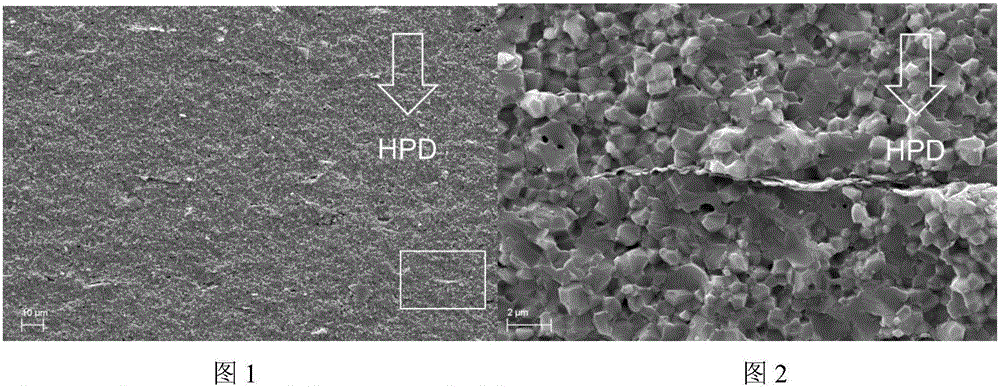

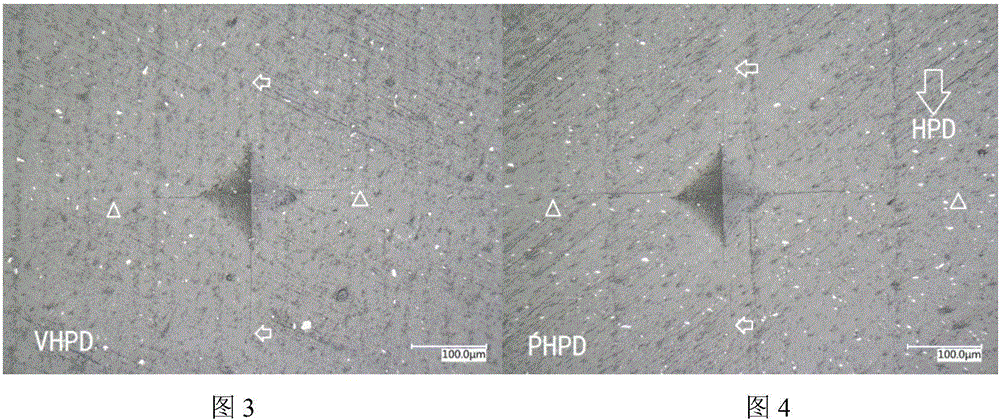

[0044] Graphene toughened Al 2 o 3 Composite ceramic material, the volume percentage of raw material components is: graphene 0.25%, Mo0.75%, Ni1.25%, MgO 0.5%, the rest is Al 2 o 3 .

[0045] The preparation method is as follows:

[0046] According to Al 2 o 3 Weigh polyethylene glycol (PEG4000) at 2% of the mass, dissolve it completely in absolute ethanol, ultrasonically disperse and mechanically stir for 10 min; weigh A1 2 o 3 And pour it into the polyethylene glycol dispersion that has been completely dissolved, ultrasonically disperse and mechanically stir for 10 minutes to obtain Al 2 o 3 -Polyethylene glycol dispersion; Al 2 o 3 -The polyethylene glycol dispersion is poured into a ball mill jar, and ball milled with cemented carbide ball YG6 for 24 hours under a nitrogen protective atmosphere, with a mass ratio of ball to material of 10:1; weigh polyvinylpyrrolidone (PVP) according to 60% of the mass of graphene , K30), make it dissolve in absolute ethanol, ul...

Embodiment 2

[0049] Graphene toughened Al 2 o 3 Composite ceramic material, the volume percentage of raw material components is: graphene 0.5%, Mo0.75%, Ni1.25%, MgO0.5%, the rest is Al 2 o 3 .

[0050] The preparation method is as follows:

[0051] According to Al 2 o 3 Weigh polyethylene glycol (PEG4000) at 2% of the mass, dissolve it completely in absolute ethanol, ultrasonically disperse and mechanically stir for 20min; weigh A1 2 o 3 and poured into the completely dissolved polyethylene glycol dispersion, ultrasonically dispersed and mechanically stirred for 20 minutes to obtain Al 2 o 3 -Polyethylene glycol dispersion; Al 2 o 3 - The polyethylene glycol dispersion is poured into a ball mill jar, and ball milled for 36 hours under a nitrogen protective atmosphere using cemented carbide ball YG6, with a mass ratio of ball to material of 12:1; weigh polyvinylpyrrolidone (PVP , K30), make it dissolve in absolute ethanol, ultrasonically disperse and mechanically stir for 20min;...

Embodiment 3

[0054] Graphene toughened Al 2 o 3 Composite ceramic material, the volume percentage of raw material components is: graphene 0.75%, Mo0.75%, Ni1.25%, MgO0.5%, the rest is Al 2 o 3 .

[0055] The preparation method is as follows:

[0056] According to Al 2 o 3 Weigh polyethylene glycol (PEG4000) at 2% of the mass, dissolve it completely in absolute ethanol, ultrasonically disperse and mechanically stir for 30min; weigh A1 2 o 3 And pour it into the polyethylene glycol dispersion that has been completely dissolved, ultrasonically disperse and mechanically stir for 30 minutes to obtain Al 2 o 3 -Polyethylene glycol dispersion; Al 2 o 3 - The polyethylene glycol dispersion is poured into a ball mill jar, and ball milled with cemented carbide ball YG6 for 48 hours under a nitrogen protective atmosphere, the mass ratio of the ball to material is 10:1; weigh polyvinylpyrrolidone (PVP) according to 70% of the mass of graphene , K30), make it dissolve in absolute ethanol, ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com