High-entropy boride-based ceramic, preparation method and applications thereof

A boride, high-entropy technology, applied in the field of ceramic cutting tools, can solve the problems that the application of boride-based ceramic materials has not been reported, and achieve shortened grain growth time, good high temperature strength and hardness, good wear resistance and The effect of cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

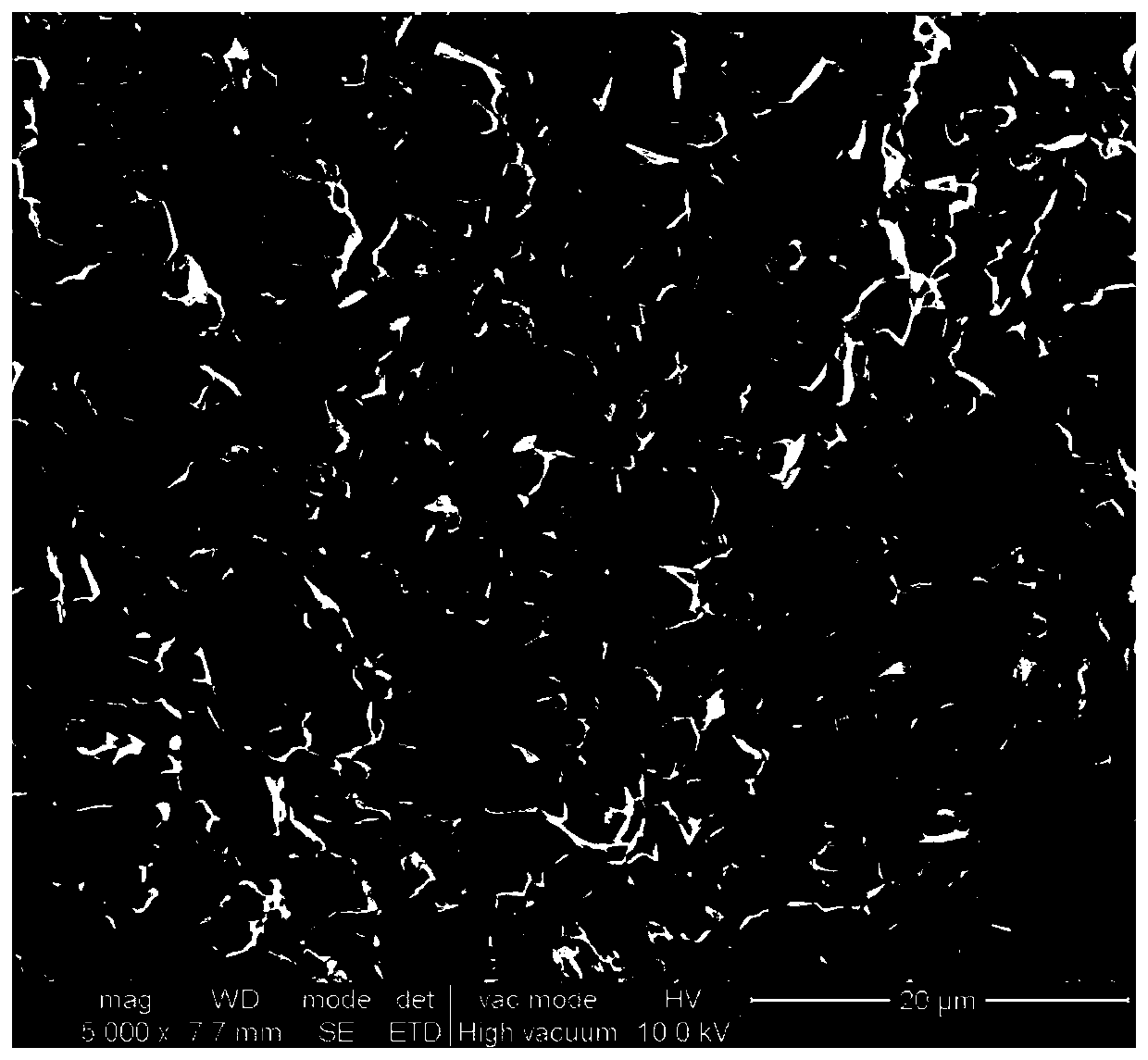

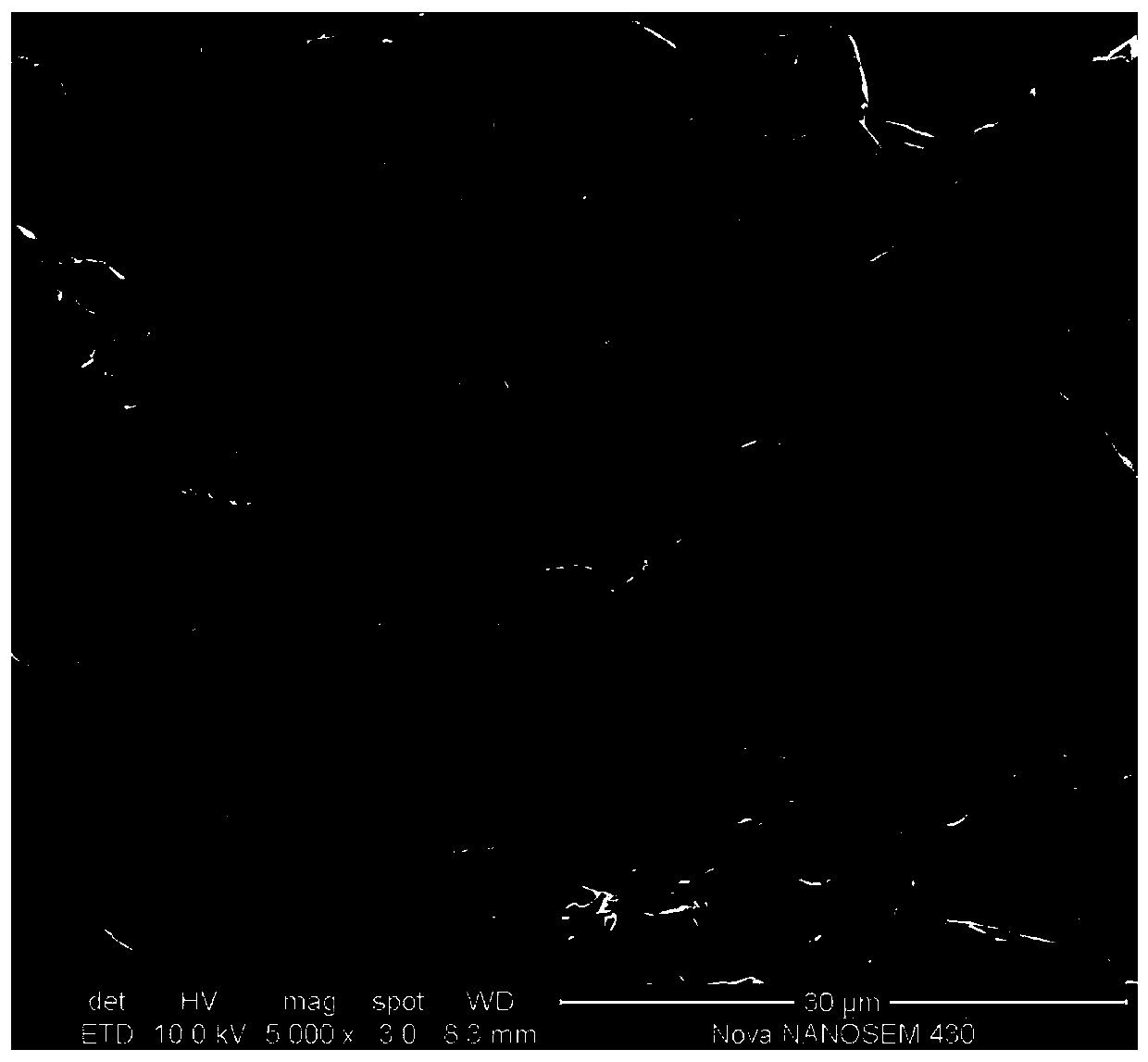

Image

Examples

Embodiment 1

[0028] 1. Preparation:

[0029] (1) with (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 Powder is (particle size4 C powder (purity is 99.5%, particle size is 1μm), SiC (purity is 99.5%, particle size is 300nm), according to (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 :B 4 C: The volume ratio of SiC is 70:15:15 for batching, ethanol is used as solvent, and cemented carbide YG6 balls are used as ball milling medium. After mixing for 6 hours at a speed of 300r / min in a planetary ball mill, a uniformly mixed (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 -B 4 C-SiC powder.

[0030] (2) will (Ti 0.2 Zr 0.2 f 0.2 Ta0.2 Cr 0.2 )B 2 -B 4 Put the C-SiC mixed powder into the graphite mold of the spark plasma sintering furnace, raise the temperature to 1000°C at a rate of 300°C / min under a vacuum of less than 1mbar, and then fill it with 1atm argon gas within 1min, after the inflation is completed , pressurize axially to 40MPa within 2 minutes, and raise the temperature to 1900°C ...

Embodiment 2

[0037] 1. Preparation:

[0038] (1) with (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 Powder is (particle size4 C powder (purity is 99.5%, particle size is 1μm), SiC (purity is 99.5%, particle size is 300nm), according to (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 :B 4 C: The volume ratio of SiC is 70:25:5 for batching, ethanol is used as solvent, and cemented carbide YG6 balls are used as ball milling medium. After mixing for 6 hours at a speed of 300r / min in a planetary ball mill, a uniformly mixed (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -B 4 C-SiC powder.

[0039] (2) will (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -B 4 Put the C-SiC mixed powder into the graphite mold of the spark plasma sintering furnace, raise the temperature to 1000°C at a rate of 300°C / min under a vacuum of less than 1mbar, and then fill it with 1atm argon gas within 1min, after the inflation is completed , pressurize axially to 40MPa within 2 minutes, and raise the temperature to 19...

Embodiment 3

[0042] 1. Preparation:

[0043] (1) with (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 Powder is (particle size4 C powder (purity is 99.5%, particle size is 1μm), SiC (purity is 99.5%, particle size is 300nm), according to (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 :B 4 C: The volume ratio of SiC is 70:5:25 for batching, ethanol is used as solvent, and cemented carbide YG6 balls are used as ball milling medium. After mixing for 6 hours at a speed of 300r / min in a planetary ball mill, a uniformly mixed (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -B 4 C-SiC powder.

[0044] (2) will (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -B 4 Put the C-SiC mixed powder into the graphite mold of the spark plasma sintering furnace, raise the temperature to 1000°C at a rate of 300°C / min under a vacuum of less than 1mbar, and then fill it with 1atm argon gas within 1min, after the inflation is completed , pressurize axially to 40MPa within 2 minutes, and raise the temperature to 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com