High-entropy metal ceramic and preparation method and application thereof

A cermet and high-entropy technology, which is applied in the field of high-entropy cermet and its preparation, can solve the unreported problems in the field of cutting tools, and achieve the effects of high toughness, improved toughness, good wear resistance and cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

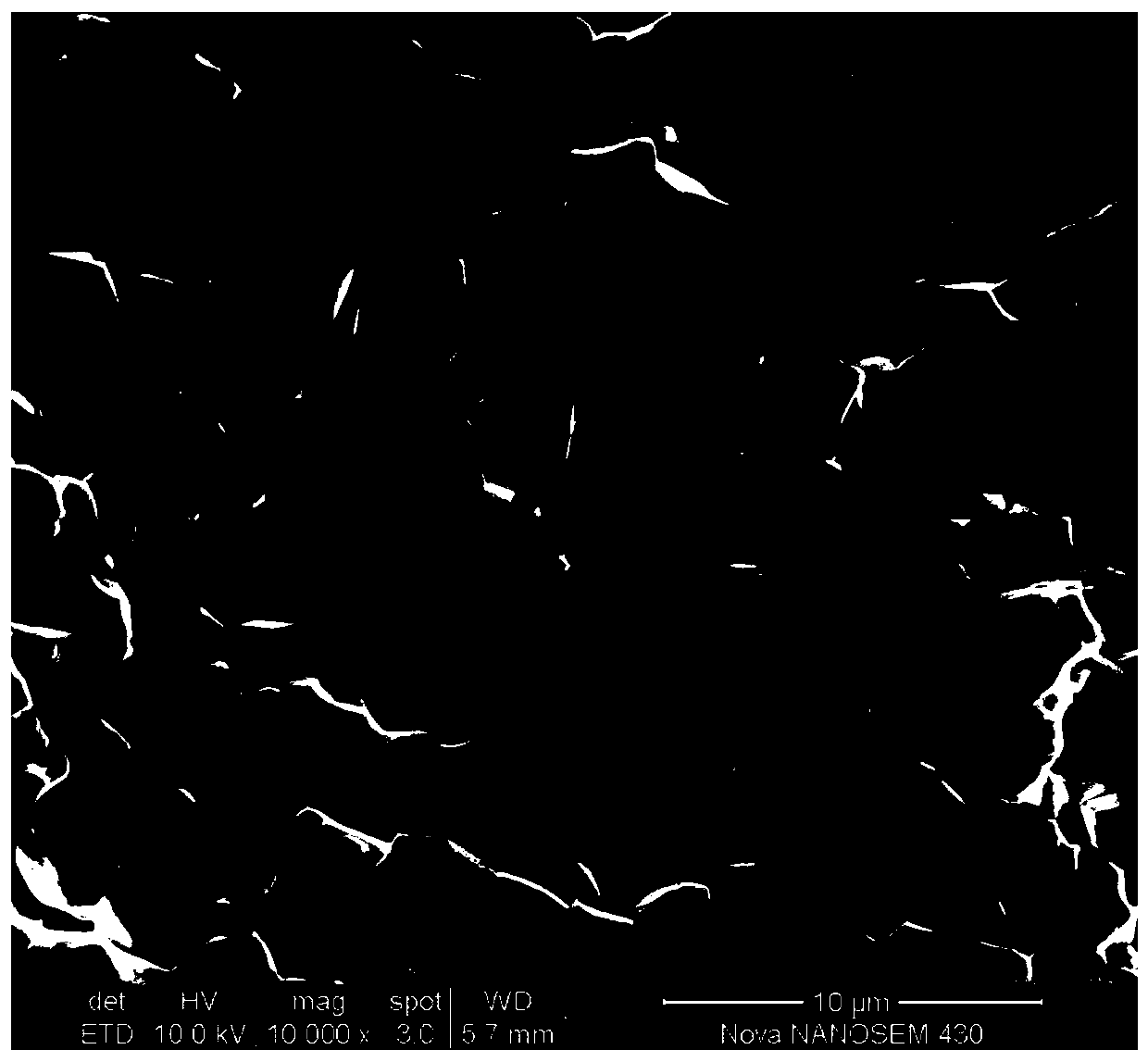

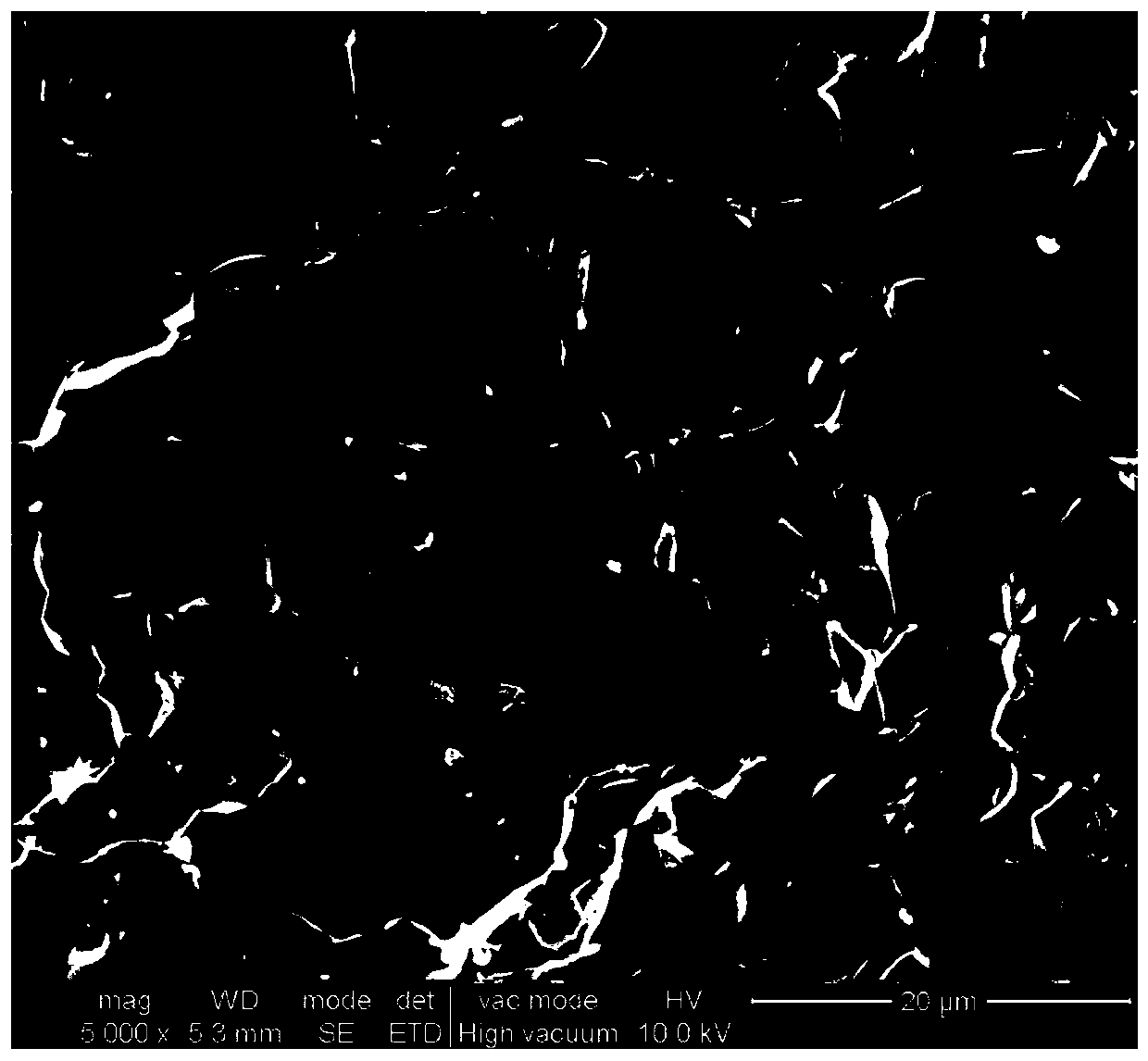

Image

Examples

Embodiment 1

[0029] 1. Preparation:

[0030] (1) with (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 The powder is (1.5μm in particle size) matrix raw material, Ni, Co, Mo powder (purity is 99.5%, particle size is 3μm) is used as binder, according to (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 : The volume ratio of Ni: Co: Mo is 78:8:8:6 for batching, with ethanol as the solvent, and cemented carbide YG6 balls as the ball milling medium. Uniform (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Ni-Co-Mo powder.

[0031] (2) The dried (Ti 0.2 Zr 0.2 Hf 0.2 Ta 0.2 Cr 0.2 )B 2 -Put the Ni-Co-Mo mixed powder into a dry pressing mold, and perform dry pressing at 200MPa to obtain a molded green body

[0032](3) Put the molded biscuit into the atmosphere sintering furnace, raise the temperature to 1000°C at a rate of 20°C / min under a vacuum of less than 1mbar, and then fill it with 1atm argon within 5min. Raise the temperature to 1650°C / min, hold for 90 minutes, then cool down to 800°C at 2...

Embodiment 2

[0039] 1. Preparation:

[0040] (1) with (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 powder (1.5 μm in particle size) as matrix raw material, Ni, Co, Mo powder (99.5% in purity, 3 μm in particle size) as binder, according to (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 : The volume ratio of Ni: Co: Mo is 72:10:11:7 for batching, with ethanol as the solvent, and cemented carbide YG6 balls as the ball milling medium. After mixing for 12 hours at the speed of 200r / min in the planetary ball mill, the mixed Uniform (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 -Ni-Co-Mo powder.

[0041] (2) The dried (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 -Put the Ni-Co-Mo mixed powder into a dry pressing mold, and perform dry pressing at 200MPa to obtain a molded green body

[0042] (3) Put the molded biscuit into the atmosphere sintering furnace, raise the temperature to 800°C at 20°C / min under a vacuum of less than 1mbar, and then fill it with 1atm argon within 5min, and start the infl...

Embodiment 3

[0045] 1. Preparation:

[0046] (1) with (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 powder (1.5 μm in particle size) as matrix raw material, Ni, Co, Mo powder (99.5% in purity, 3 μm in particle size) as binder, according to (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 : The volume ratio of Ni: Co: Mo is 67:13:12:8 for batching, with ethanol as the solvent, and cemented carbide YG6 balls as the ball milling medium. After mixing for 12 hours at the speed of 200r / min in the planetary ball mill, the mixed Uniform (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 -Ni-Co-Mo powder.

[0047] (2) The dried (Ti 0.2 Zr 0.2 f 0.2 Ta 0.2 Cr 0.2 )B 2 -Put the Ni-Co-Mo mixed powder into a dry pressing mold, and perform dry pressing at 200MPa to obtain a molded green body

[0048] (3) Put the molded biscuit into the atmosphere sintering furnace, raise the temperature to 1000°C at a rate of 20°C / min under a vacuum of less than 1mbar, and then fill it with 1atm argon within 5min. Raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com