Alumina-based composite ceramic knife material and microwave preparation method thereof

A tool material and composite ceramic technology, which is applied in the field of alumina-based composite ceramic tool material and its microwave preparation, can solve the problems of low density, long heat preservation time, high cost, etc., and achieve the purpose of inhibiting the growth of material grains and improving the structure The effect of density and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

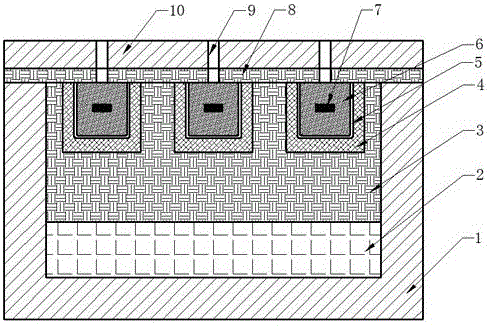

Embodiment 1

[0031] By mass percentage Al 2 O 3 61.4%, TiC is 30%, Mo, Ni, MgO, Y 2 O 3 , Cr 3 C 2 The ingredients are respectively 3%, 3%, 0.65%, 0.65%, and 1.3%. The Al 2 O 3 The particle size of the powder particles is 0.6μm, the particle size of TiC powder is 1μm, using alcohol as the ball milling medium, ball milling in a QM~3SP2 planetary ball mill at 200rpm for 48h, and then adding a 5wt% PVA solution to the raw materials , Continue ball milling for 2 hours; take out the mixture and place it in a drying oven for drying, then sieving. The obtained mixture is put into a mold, and a green body with a certain shape and strength is obtained by a cold pressing method through a pressure of 200 MPa, and the pressure is maintained for 3 minutes. Place the pressed blanks in a special multi-cavity microwave heat preservation device, put them into the NJZ5~1 vacuum microwave sintering furnace, heat up to 1700°C at a heating rate of 40-50°C / min and keep the temperature for 10 minutes, and complete...

Embodiment 2

[0034] By mass percentage: Group I Al 2 O 3 Is 71.4%, TiC is 20%, group II Al 2 O 3 Is 61.4%, TiC of group III is 30%, Al 2 O 3 51.4%, 40% TiC, additives Mo, Ni, MgO, Y 2 O 3 , Cr 3 C 2 The content remains the same, and they are 3%, 3%, 0.65%, 0.65%, and 1.3% ingredients respectively. The Al 2 O 3 The particle size of the powder particles is 0.6μm, the particle size of TiC powder is 1μm, using alcohol as the ball milling medium, ball milling in a QM~3SP2 planetary ball mill at 200rpm for 48h, and then adding a 5wt% PVA solution to the raw materials , Continue ball milling for 2 hours; take out the mixture and place it in a drying oven for drying, then sieving. The obtained mixture is put into a mold, and a green body with a certain shape and strength is obtained by a cold pressing method through a pressure of 200 MPa, and the pressure is maintained for 3 minutes. Put the three types of pressed blanks into a special multi-cavity microwave heat preservation device, put them into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com