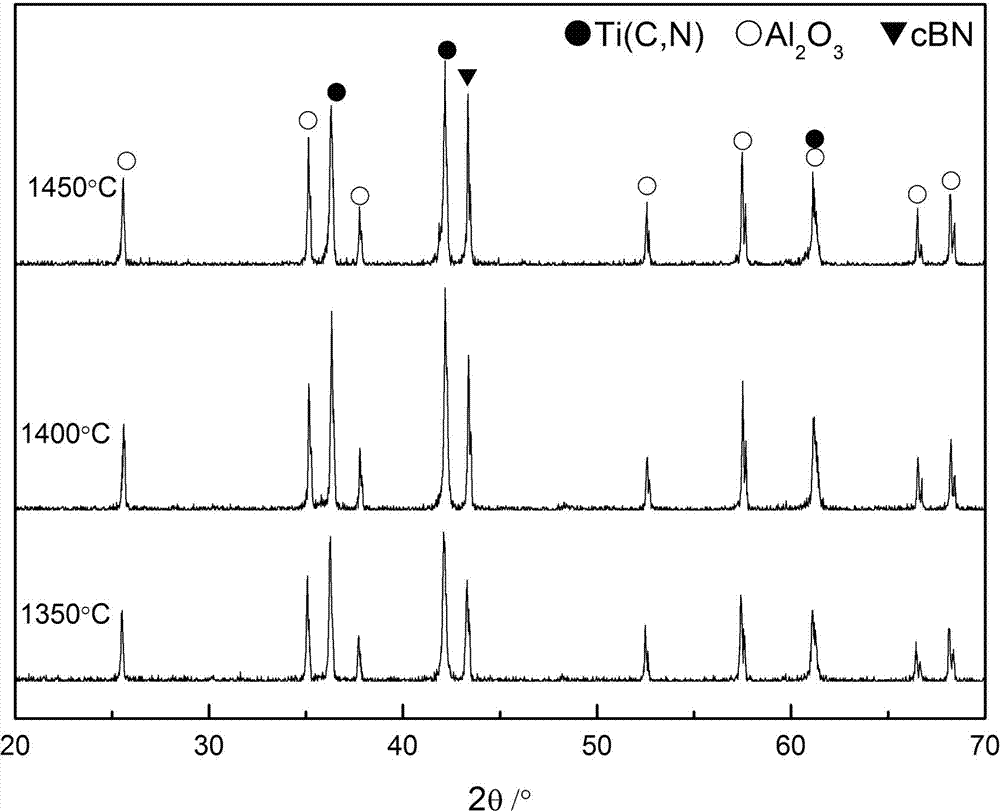

Al2O3-Ti(C,N)-cBN ceramic tool material and preparation method thereof

A technology of al2o3-ti and ceramic cutting tools, which is applied in the field of materials, can solve problems such as harsh reaction conditions, unsatisfactory performance, and complicated operation, and achieve the effects of enhanced interface bonding strength, low preparation cost, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

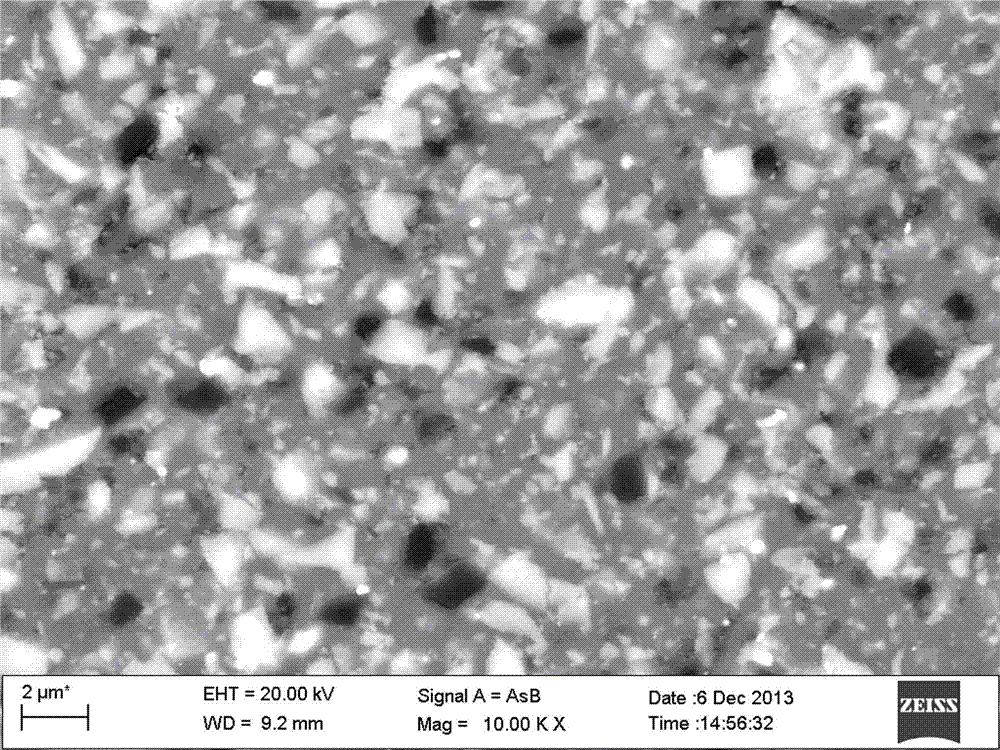

Embodiment 1

[0041] Prepare Al 2 o 3 powder, Ti(C,N) powder as the main raw material; Al 2 o 3 The particle size of the powder is 0.08~0.2μm, accounting for 65% of the total volume of all main raw materials; the particle size of Ti(C,N) powder is 0.08~0.1μm, accounting for 35% of the total volume of all main raw materials;

[0042] Ti(C,N) in Ti(C,N) powder 1-X N X ) weight content ≥ 99.9%, where x = 0.3; cBN powder cubic phase BN ≥ 99%;

[0043] Prepare cBN powder as an auxiliary raw material, the particle size of cBN powder is 0.5~1μm, accounting for 5% of the total volume of all main raw materials;

[0044] Prepare Ti powder as an additive, with a particle size of ≤3 μm, and the additive accounts for 1% of the total volume of all main raw materials;

[0045] Dissolve the dispersant ammonium polyacrylate in water to make a primary dispersant solution, the weight concentration of ammonium polyacrylate is 0.6%; put the prepared main raw material and primary dispersant solution in a b...

Embodiment 2

[0049] Method is with embodiment 1, and difference is:

[0050] Prepare Al 2 o 3 powder, Ti(C,N) powder as the main raw material; Al 2 o 3 Powder accounts for 70% of the total volume of all main raw materials; Ti(C,N) powder accounts for 30% of the total volume of all main raw materials; Ti(C,N) powder in Ti(C,N) 1-X N X ) x = 0.5;

[0051] The particle size of the auxiliary raw material cBN powder is 2~3μm, accounting for 0.5% of the total volume of the main raw material;

[0052] Prepare Al powder as an additive, and the additive accounts for 0.5% of the total volume of all main raw materials;

[0053] The weight concentration of ammonium polyacrylate in the primary dispersant solution is 0.8%; the prepared main raw material and the primary dispersant solution are placed in a ball mill for ball milling and mixing for 16 hours, and then dried at 90°C for 40 hours to obtain Al 2 o 3 -Ti(C,N) mixed powder; the volume ratio of the primary dispersant to the main raw mater...

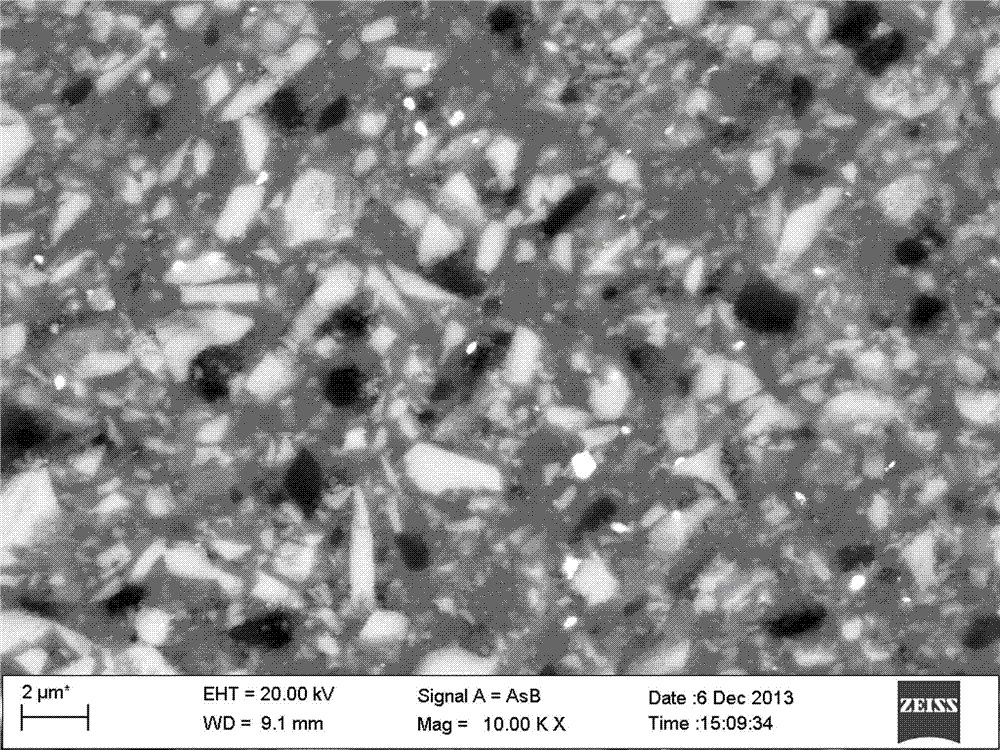

Embodiment 3

[0057] Method is with embodiment 1, and difference is:

[0058] Prepare Al 2 o 3 powder, Ti(C,N) powder as the main raw material; Al 2 o 3 Powder accounts for 85% of the total volume of all main raw materials; Ti(C,N) powder accounts for 15% of the total volume of all main raw materials; Ti(C,N) powder in Ti(C,N) 1-X N X ) x = 0.7;

[0059] The particle size of the auxiliary raw material cBN powder is 3~5μm, accounting for 5% of the total volume of all main raw materials;

[0060] Prepare Ti powder and Ni powder to be mixed by equal mass as an additive, and the additive accounts for 3% of the total volume of all main raw materials;

[0061] The weight concentration of ammonium polyacrylate in the primary dispersant solution is 1.0%; the prepared main raw material and the primary dispersant solution are placed in a ball mill for ball milling and mixing for 20 hours, and then dried at 100°C for 36 hours to obtain Al 2 o 3 -Ti(C,N) mixed powder; the volume ratio of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com