High-performance ceramic knife and preparation method thereof

A ceramic knife, high-performance technology, applied in the field of ceramic knives, can solve the problems of not having high hardness, brittleness, insufficient toughness, etc., and achieve the effect of high sharpness and durable sharpness, high strength and toughness, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

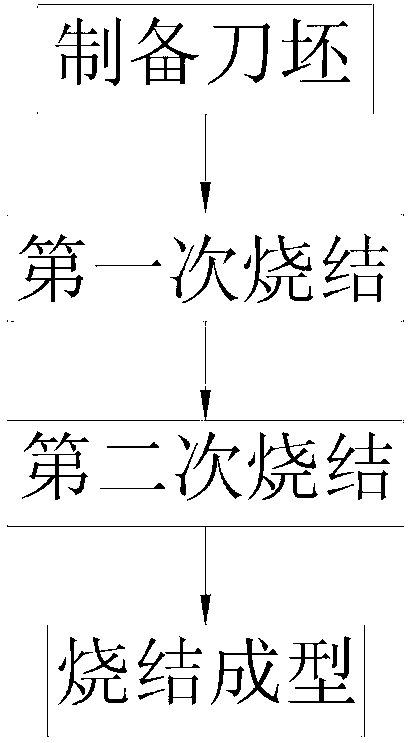

Method used

Image

Examples

Embodiment Construction

[0018] In the present embodiment, the raw materials used in the ceramic knife of the present invention are calculated by weight percentage, and it consists of the following components:

[0019] ZrO 2 and HfO 2 The mixture of 93~94wt%; Y 2 o 3 5~6wt%; Al 2 o 3 0.2~1wt%. Specifically, the first scheme is: ZrO 2 and HfO 2 The mixture of 93wt%; Y 2 o 3 6wt%; Al 2 o 3 1wt%. The second option is: ZrO 2 and HfO 2 The mixture of 94wt%; Y 2 o 3 5.5wt%; Al 2 o 3 0.5wt%. The third option is: ZrO 2 and HfO 2 The mixture of 93.5wt%; Y 2 o 3 5.5wt%; Al 2 o 3 1wt%. Of course, there are other specific solutions, such as: ZrO 2 and HfO 2 The mixture of 93.8wt%; Y 2 o 3 5.8wt%; Al 2 o 3 0.4wt%. In short, any ZrO 2 and HfO 2 The content of the mixture is in the range of 93 ~ 94wt%, Y 2 o 3 The content of Al is in the range of 5-6wt%, Al 2 o 3 The content is in the range of 0.2 to 1wt%, all falling within the protection scope of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com