Ceramic knife and preparation method thereof

A technology of ceramic knives and raw materials, which is applied in the field of new materials, can solve the problems that cannot meet the high demand of ceramic knives, and achieve the effect of light weight, high hardness and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

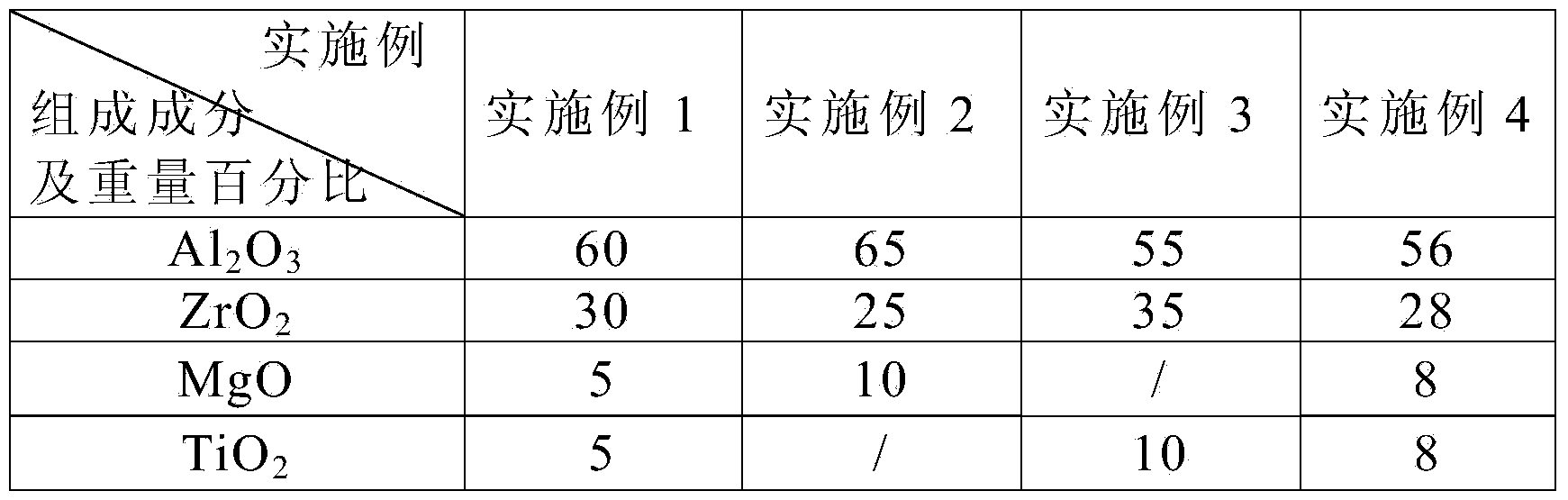

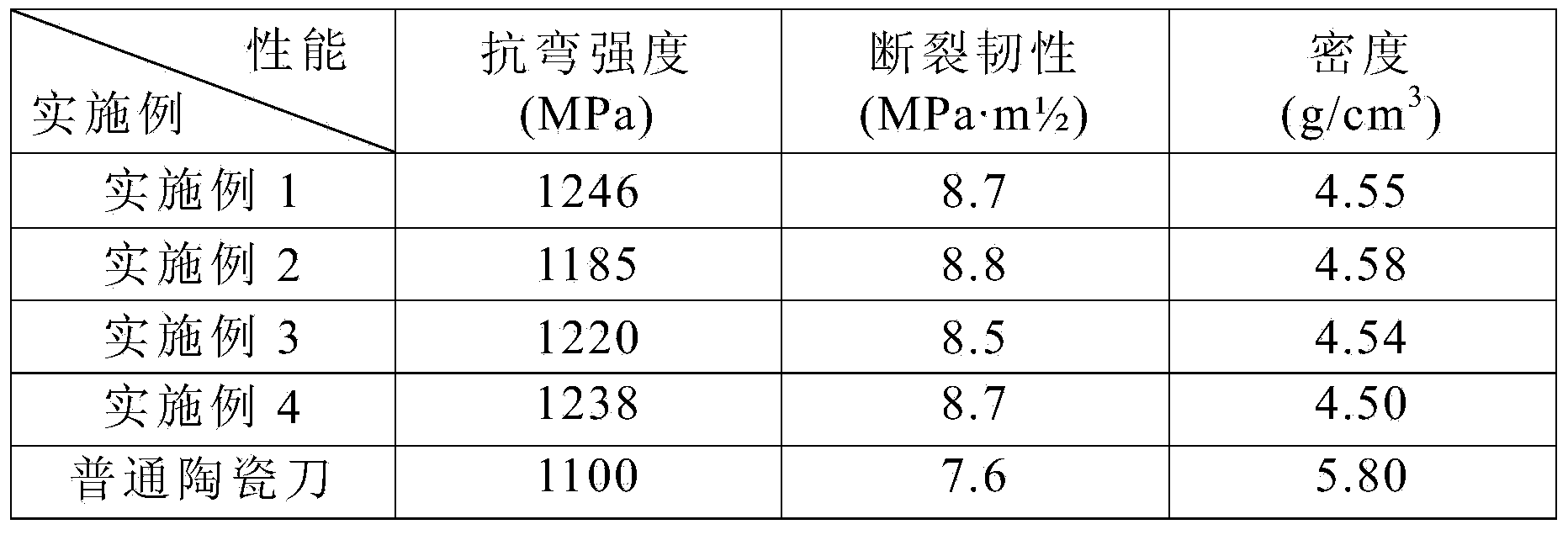

[0029] Weigh raw materials: weigh raw materials according to the composition and mass percentage of the ceramic knife raw materials described in Table 1, Example 1, and pour the weighed raw materials into a ball mill for mixing for 60 min; wherein the Al 2 o 3 The particle size is 5μm, ZrO 2 The particle size of MgO is 0.5 μm, the particle size of MgO is 8 μm, and the particle size of TiO 2 The particle size is 0.1μm, ZrO 2 The stabilizer is Y 2 o 3 , Y 2 o 3 accounted for ZrO 2 The mass fraction of the product is 2%;

[0030] Compression forming: the above-mentioned ceramic knife raw material mixed uniformly is pressed into a ceramic knife blank under 55MPa by cold isostatic pressing;

[0031] Sintering: Put the ceramic knife blank into a vacuum sintering furnace, pre-fire it to 1100°C at a heating rate of 0.8°C / min, keep it at 110°C for 2 hours, and then heat it to 1500°C at a heating rate of 2.5°C / min. Keep the temperature at 1500°C for 3 hours, and finally cool in...

Embodiment 2

[0033]Weigh raw materials: weigh raw materials according to the composition and mass percentage of the ceramic knife raw materials described in Table 1, Example 2, and pour the weighed raw materials into a ball mill for mixing for 80 min; wherein the Al 2 o 3 The particle size is 7μm, ZrO 2 The particle size of MgO is 0.6 μm, the particle size of MgO is 10 μm, and the particle size of TiO 2 The particle size is 0.3μm, ZrO 2 The stabilizer is CeO 2 , CeO 2 accounted for ZrO 2 The quality fraction of the product is 3%;

[0034] Compression forming: the above-mentioned ceramic knife raw material mixed uniformly is pressed into a ceramic knife blank under 58 MPa by cold isostatic pressing;

[0035] Sintering: Put the ceramic knife blank into a vacuum sintering furnace, pre-sinter it to 1150°C at a heating rate of 0.6°C / min, keep it at 1150°C for 1 hour, and then heat it to 1550°C at a heating rate of 2°C / min. Keep the temperature at 1550°C for 3 hours, and finally cool in t...

Embodiment 3

[0037] Weigh raw materials: weigh raw materials according to the composition and mass percentage of the ceramic knife raw materials described in the embodiment 3 of table 1, pour the weighed raw materials into a ball mill and carry out mixing for 120min; wherein the Al 2 o 3 The particle size is 10μm, ZrO 2 The particle size of MgO is 0.8μm, the particle size of MgO is 15μm, and the particle size of TiO 2 The particle size is 0.5μm, ZrO 2 The stabilizer is Y 2 o 3 , Y 2 o 3 accounted for ZrO 2 The mass fraction of 4%;

[0038] Compression forming: the above-mentioned ceramic knife raw material mixed uniformly is pressed into a ceramic knife blank under 60 MPa by cold isostatic pressing;

[0039] Sintering: Put the ceramic knife blank into a vacuum sintering furnace, pre-fire it to 1000°C at a heating rate of 0.5°C / min, keep it at 1000°C for 2 hours, and then heat it to 1450°C at a heating rate of 1.5°C / min. Keep the temperature at 1450°C for 2 hours, and finally cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com